+86 1525 3141 880

+86 1525 3141 880

HOME >> Support and Service >> CNC FAQs

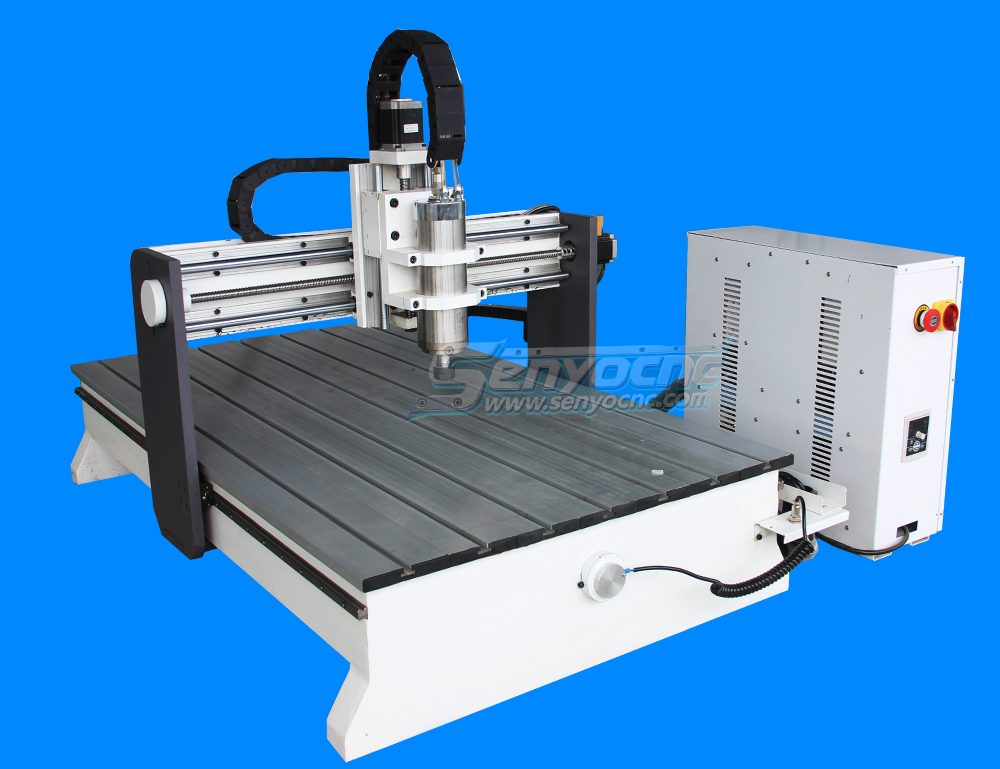

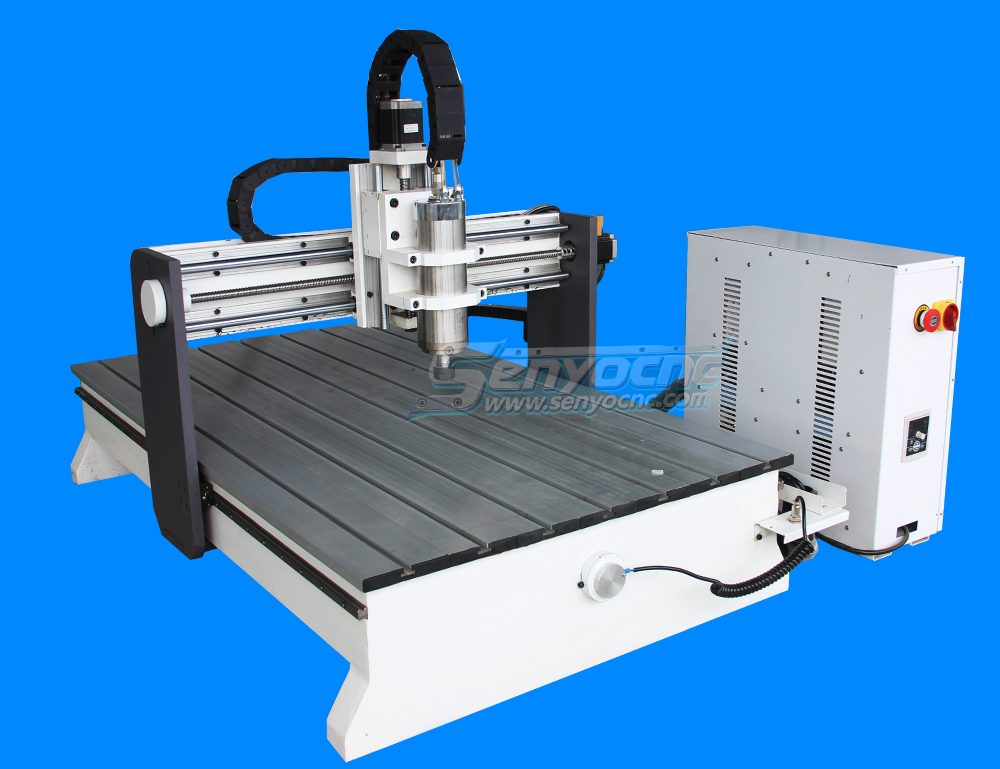

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

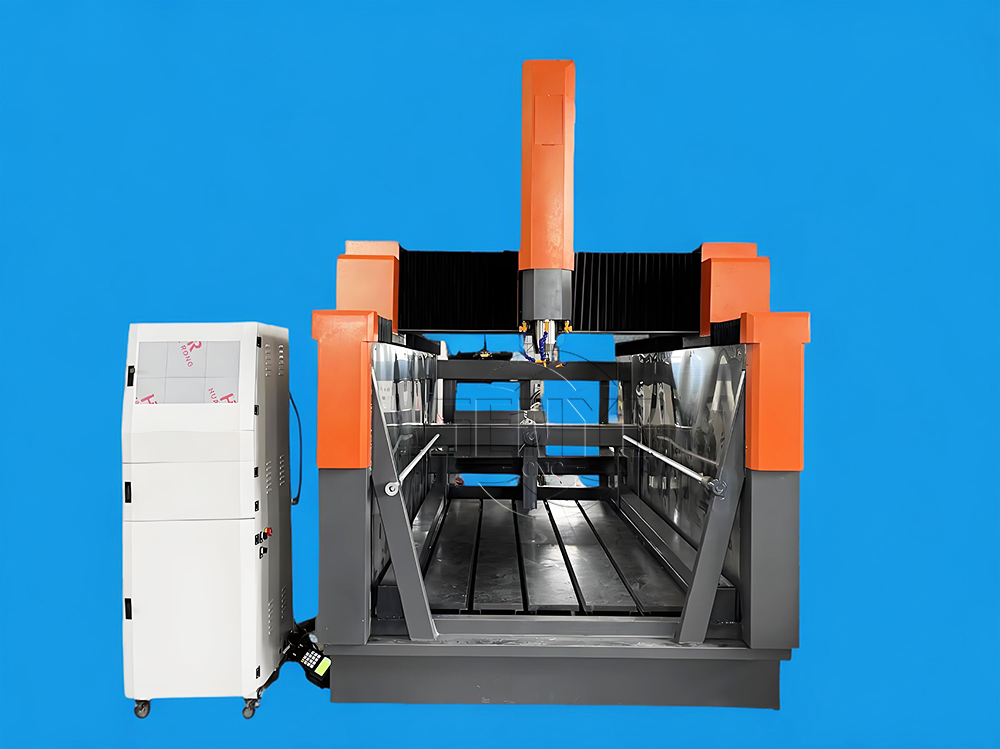

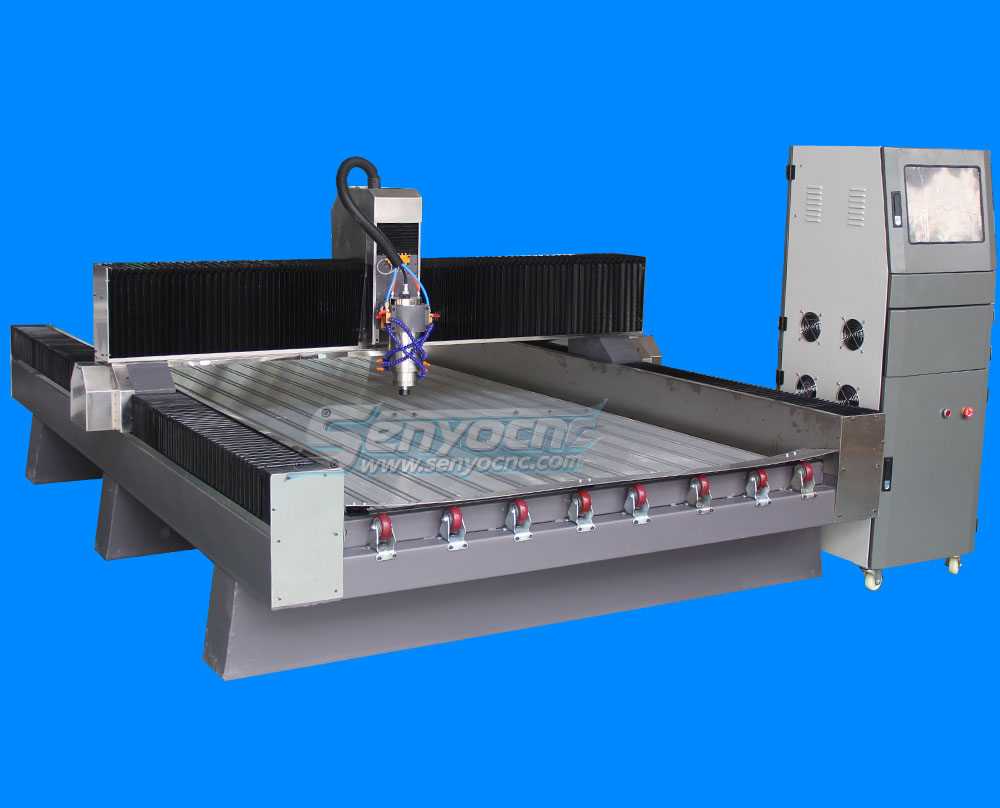

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining

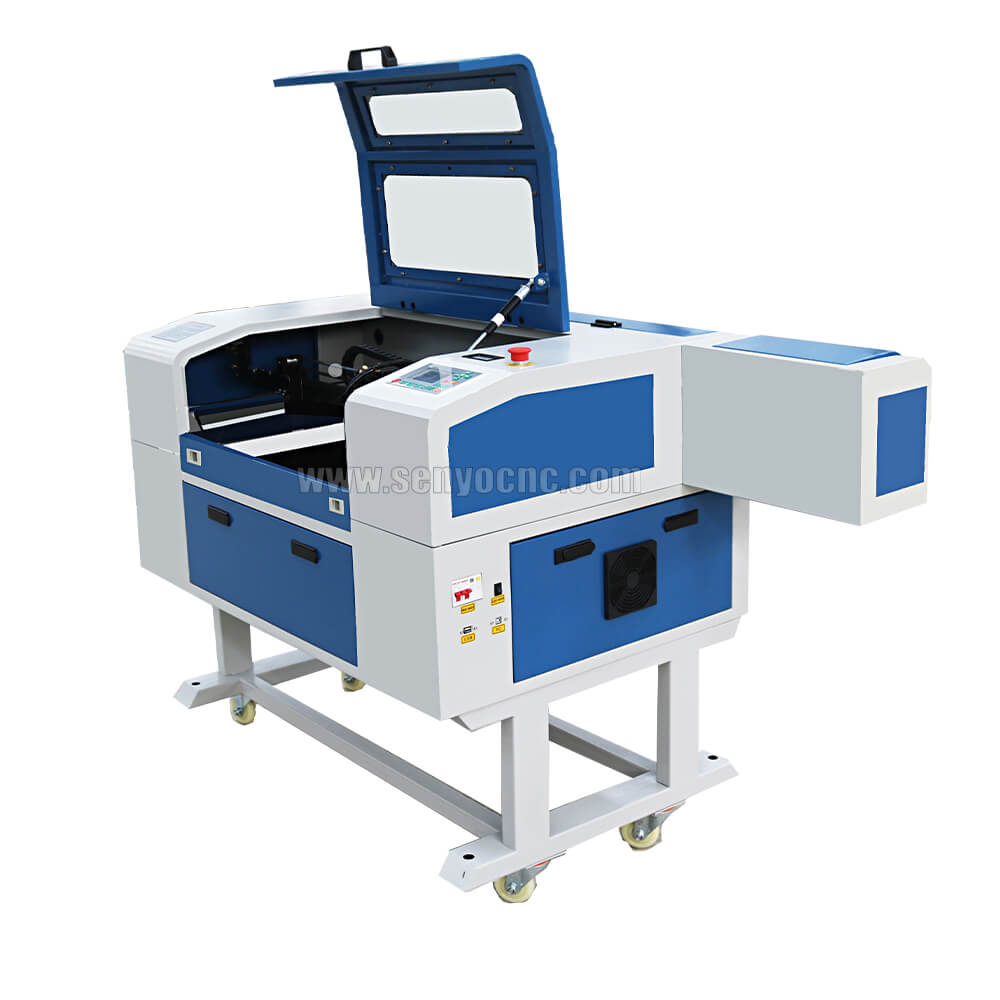

3020 40W Mini CO2 Laser Engraving Cutting Machine

New Design Mini Stone CNC Machine for Marble, Granite and Quartz

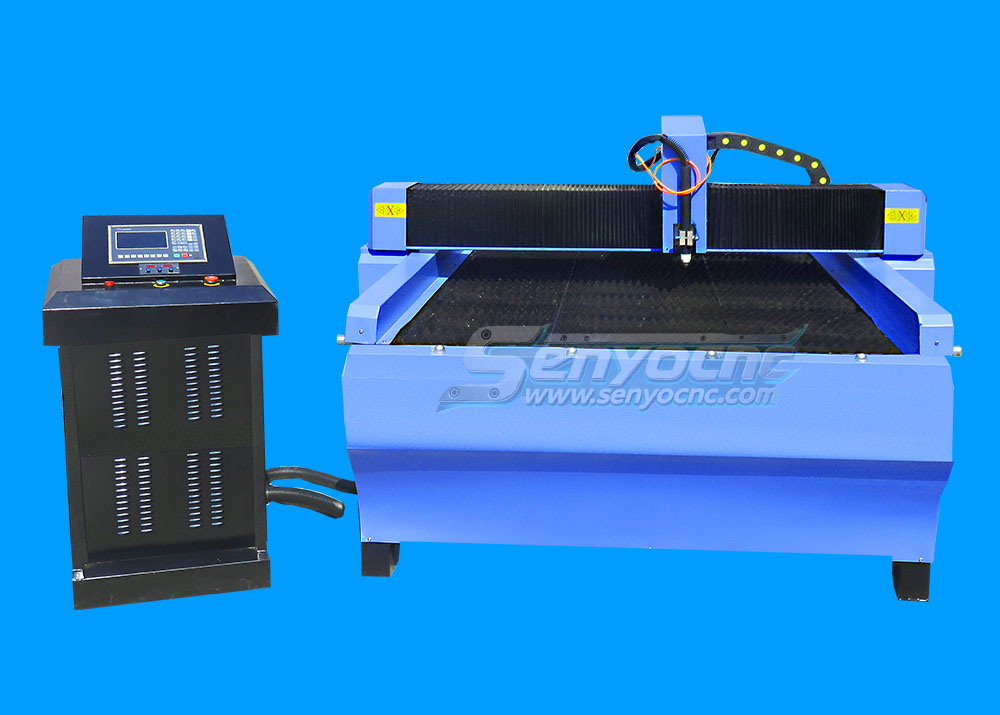

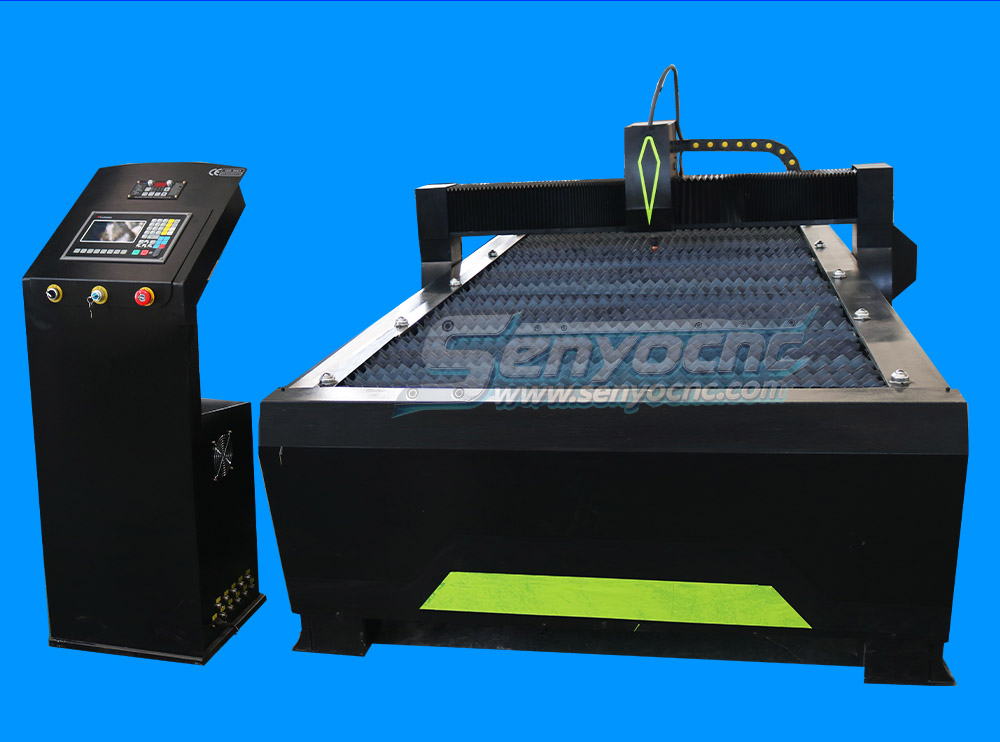

Portable CNC Flame Cutting Machine with Plasma Torch for Sale

High-Precision Mini Hobby CNC Plasma Cutting Machine for Metal

Mini CNC Plasma Cutter With Rotary

4 Axis 1325 Sculpture Machine Cnc Carving Marble Granite Stone Cnc Router

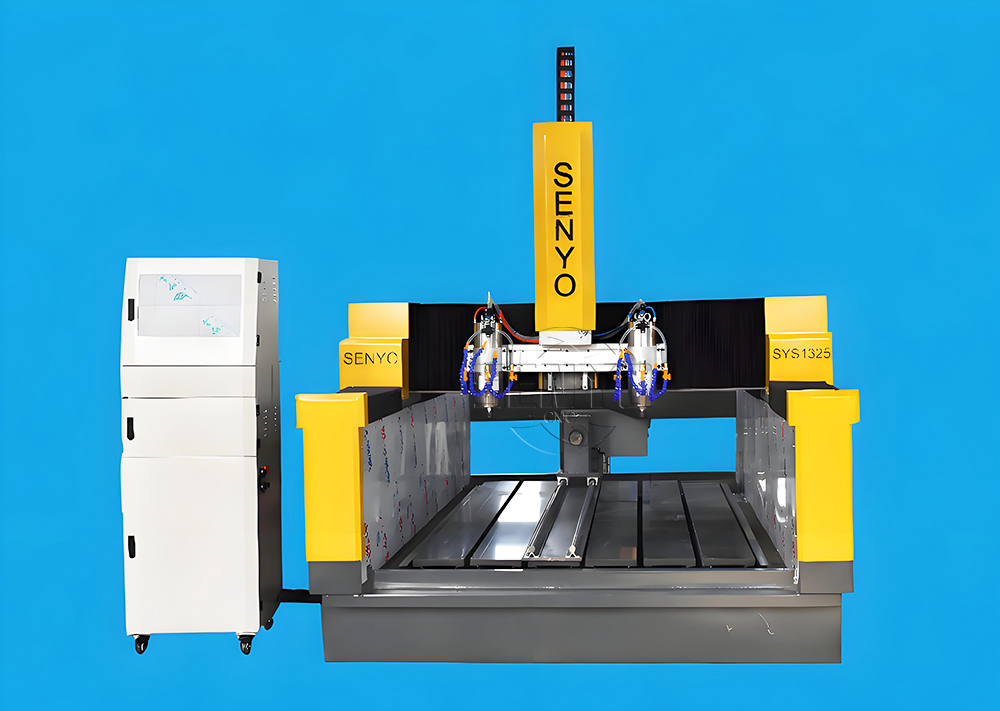

Z Height 1000MM 4-AXIS Stone Engraving CNC Machine Heavy-duty Stone CNC Machine Stone Relief Carving CNC For Sale

4030 portable mini co2 laser carving and desktop rubber stamp laser engraving machine

Stone CNC Router For Kitchen sink tile carving and cutting Marble, Granite and Quartz

Robust CNC Plasma Cutting Machines with Flame Cut Head for Heavy-Duty Industrial Use

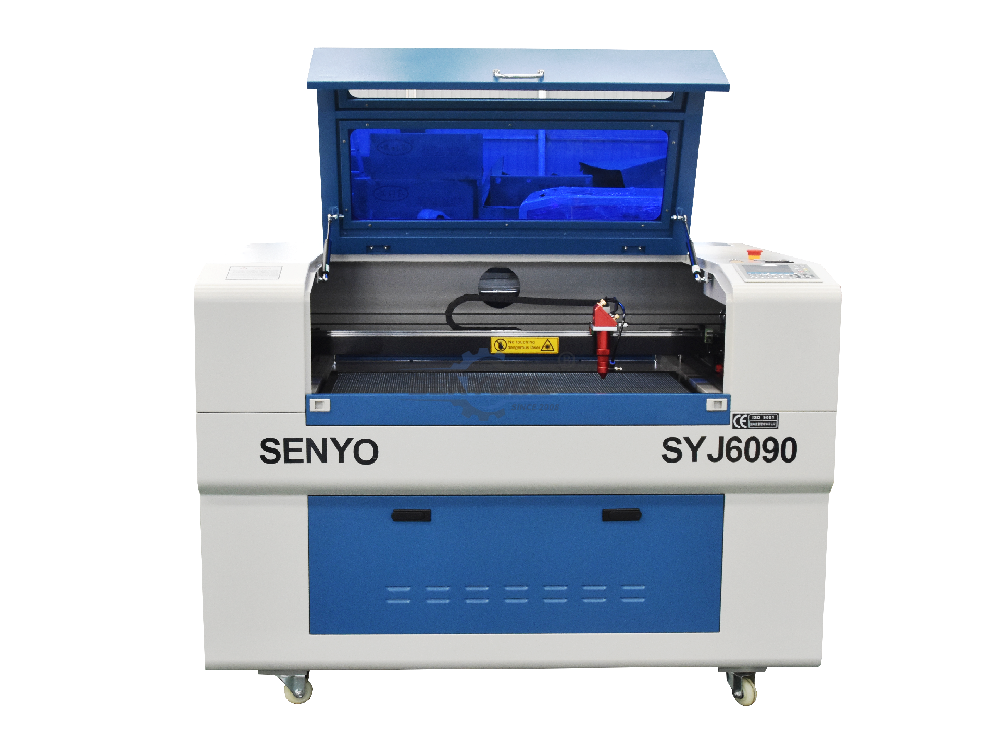

Small Portable CO₂ Laser Cutter Engraving for DIY & Business – Ideal for Wood, Acrylic, Leather

1325 3 Axis 4x8 CNC Stone Router for Sale

Mini CO2 Laser 5030 Cutting Engraving Machine For Sale

Portable CNC Plasma Flame Cutting Machine for Sale at Cost Price

Portable Cnc Plasma Oxyfuel Sheet Metal Cutting Machine for sale

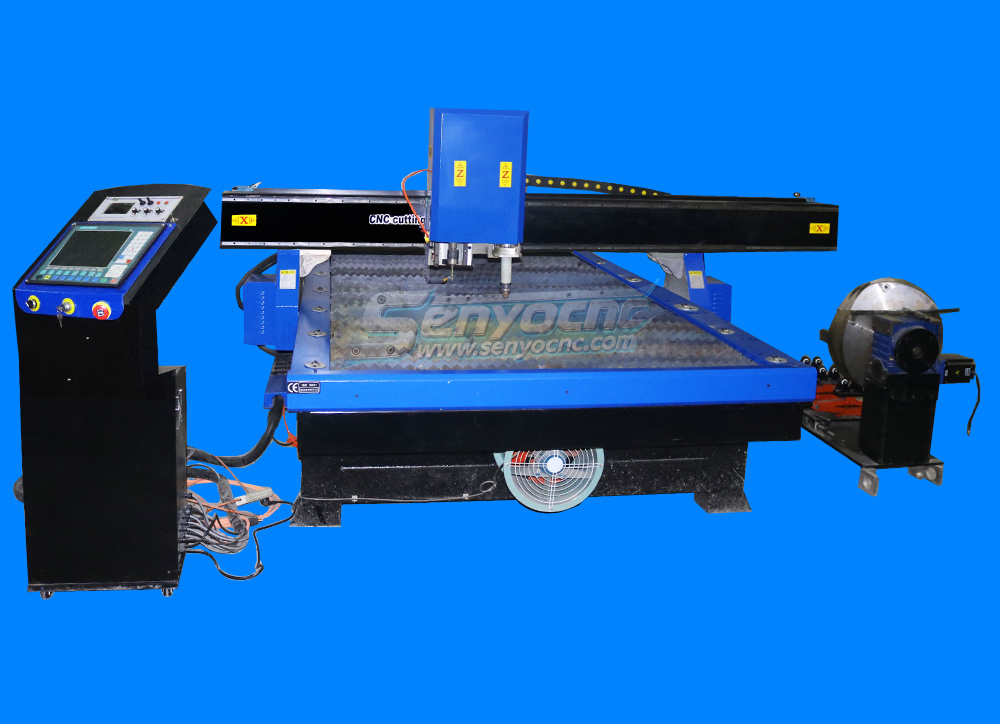

CNC Plasma Cutters for Customized Metalwork –Rotary&Drilling Head

Small Table design 6040 Easy Move CO2 Hobby Laser Cutter Machine for Beginners

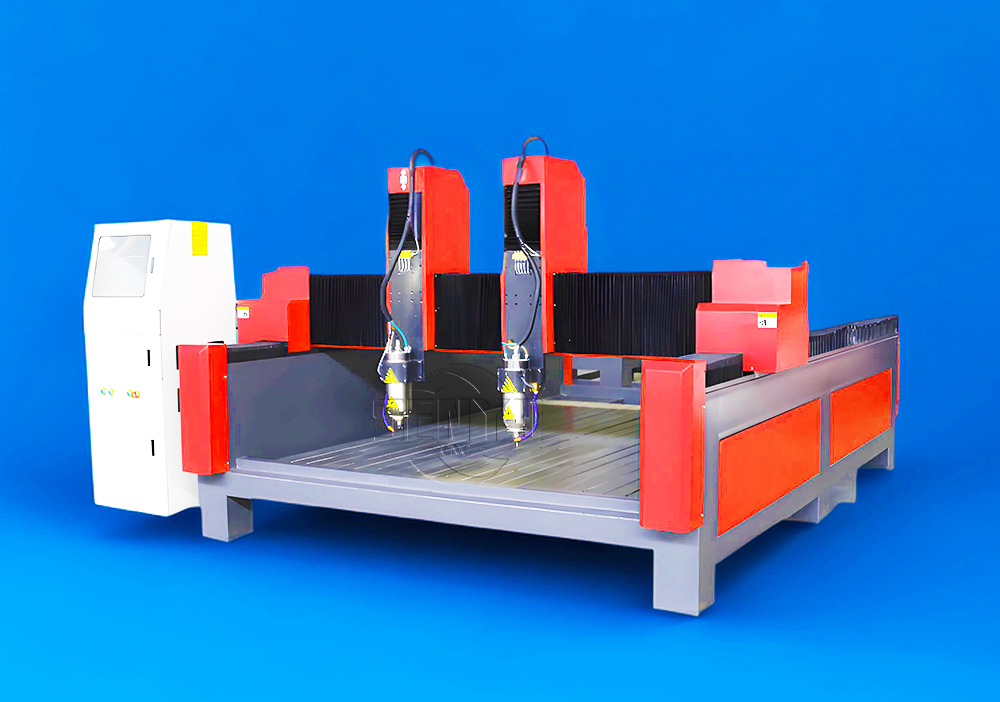

High-Efficiency 2 Heads CNC Machine for Aluminum Stone Marble Engraving & Cutting

Best CNC 2 Spindle 4-AXIS Stone Carving Machine High-precision Stone Carving Stone Countertop Fabrication

Top Rated 2x3 CO2 Hobby Laser Cutting Machine for Sale at Affordable Price

Best 4x8 CNC Plasma Cutter Table for Sale at Affordable Price

Entry Level CO2 Hobby Laser Cutter Machine for Beginners

Top CNC Plasma Cutters for Automotive, Aerospace, and Manufacturing Industries

Precision Stone Engraving Machines for Memorials & Signs

Portable Co2 9060 Laser Nonmetal Cutting Engraving Machine

1090 CO2 Laser Machine with Ruida Controller for Non-metal Glass Acrylic Engraving Cutting

Entry Level 9060 CO2 Hobby Laser Cutter Machine for Beginners

Just like the CNC router, the manually operated router table also makes work in the wood industry and the craft sector considerably easier. Compact bench routers are available in a wide variety of designs and variants.

When you want to buy a milling machine to make some work steps easier or to manufacture individual workpieces, there is a fundamental question to ask: “What is essential for you to take into consideration when you buy a CNC Router?

The size of the material

Before you start to look for a manufacturer, you should think about the

size of the desired material you want to machine because the working

area determines the maximum size of the material. Maybe you want to

machine larger workpieces in the future. Think of the biggest

measurements which come to your mind and then look for a CNC router in

that size.

Type of milling spindle

It often depends on the material which milling spindle you have to use.

Softwood or plastic, for example, require less drive power than solid

materials like stainless steel. There are standard milling motors with

different performances, and for high-end milling operations, there are

various high-frequency spindles on the market. A trustworthy

manufacturer should be able to offer both kinds of spindles.

Hardness and resistance of the material

Solid materials such as steel or granite offer more resistance to the

whole machine construction than soft materials. The harder the material,

the more stable the machine has to be built. A CNC router which can

machine stainless steel and granite with high precision is usually more

expensive than a CNC router which is only made to mill soft materials.

Precision

In general, only a professional mounted CNC Router with high-quality

components can provide highly precise milling results. The components

should be well adapted to the machined material. Before shipping, the

machine should have been extensively tested.

These questions will help you to find the right CNC Router:

How big is the material that you want to process?

What kind of milling spindle do you need for your material?

How hard is the material which you want to machine?

Which extra components do you need for your application (e.g. spray cooling, additional stability)?

A CNC router can machine a lot of different materials.

Here listed just a few materials that can be machined 2D or 3D:

Metals / Non-ferrous metals

Brass

aluminium

titanium

Noble metals such as silver, gold

Steel and cast steel

Wood

multiplex

plastics

acrylic glass

Granite and marble

It is important to know that a few materials require spray cooling during the machining process, either for cooling down the milling tool, the material or to bind the chips. What can happen if a spray cooling is necessary but there isn’t any during the milling operation?

Chips can clog or glue the grooves of the milling tool until it breaks.

The blades of the milling cutter can get blunt quickly which prevents accurate milling results.

Plastic can melt if it becomes too hot.

As already mentioned, CNC routers are operated by a computer. The required controlling commands, the so-called G-code, are successively listed in a CNC program. Each G-code-command starts with the letter „G“ followed by an instruction of numbers and types telling the machine in which direction it is supposed to move the milling cutter through the material. The computer transfers the G-code-commands to the control unit which implements them into machine movements.

Formerly the operator had to write the G-code by hand which required programming skills and was very time-consuming. Today there is no need to do this anymore. There are many CAD-CAM software solutions which turn the drawing directly into G-Code.

As the rotating milling tool penetrates the clamped workpiece, it executes a cutting movement. It depends on the tool cutting geometry on how the material is chipped. The G-Code-commands determine the moving direction itself. Both the G-code-commands and the tool cutting geometry ensure the desired shape.

To understand what exactly a CNC Router is, it is important to know what the word CNC means.CNC is an abbreviation of the English description “computerized numerical control“, and refers to an electronic method for controlling machine tools. Consequently, a CNC Router Machine is nothing more than a machine tool, which is numerically driven with computer assistance to process a variety of materials, such as Metals, wood, granite and much more.

A CNC router can mill complex shapes and fine contours in different materials by moving a high-quality tool through the clamped workpiece on a least three axis. The bridge itself is the X-axis and its back- and forward-movement symbolises the Y-axis. The up- and down movement of the milling tool stands for the Z-axis. The bridge looks like a portal, and this is why a CNC Router is also well-known as a portal milling machine.

Laser engraving or laser cutting is to converge the laser beam into a small spot through a focusing mirror and project it onto the

surface of an object. The focal point reaches a high power density. At this time, the irradiated part of the material is quickly heated

and vaporized, and the laser beam and the material move relatively linearly, so as to realize laser engraving cutting plans.

When the laser engraving machine or laser cutting machine is working for a long time, the optical path will deviate, which will affect the

cutting effect. Only the perfect cooperation of laser tube, reflecting mirror frame (A, B, C), focusing lens and corresponding

adjustment device can achieve the best effect and process the best projects. This is the core part of using CO2 laser machine.

Therefore, it is very necessary to check the laser beam path and adjust it regularly .

You are welcome to get a free quotation by flling up the form with name, email, detailed address, product and requirements,

we'll estimate the shipping cost for your CNC machine.

Please note, customs fees and additional fees may apply for international shipments. Contact your local customs office for more

information.

If you want to get the final price, please contact us to get a free quotation, we'll calculate the final price of the required CNC machine.

1. When laser engraving with gradient, double phenomenon.

This phenomenon occurs when the slope of words carved smaller, usually the reason is "wide" setting slope too large, cause

calculation errors, please set "wide" itle slope.

2. If you only can move a graphic with one direction, please click " Shft" or "Ctrl" to recover.

3. PLT format cannot to engrave.

There are two reasons, one is the graphic is not closed, the other is graphic double. Please detect this phenomenon with "data

detect" tools.

4. The size is not same with laser engraving and cutting samples.

Open the item "laser engraving machine set", adjust the pulse.

5. The edge is irregularity when laser engraving.

The edge is iregularity maybe happen when you use the DSP laser engraver sofware, that means "burr", this is mainly caused by

mechanical return clearance, this is the solution.

a. Draw a box (rectangular or square), set work mode for the laser engraving machine, the sculpture is 0. 5 mm instead, then see

laser engraving effect, theretically, should be aligned, namely the odd interlaces did edge should be aligned, even did edge also

should be aligned, only the odd and even did not have a ittle.

b. When you open "set laser engraving parameters", the parameters for different. laser engraving speed can be seen, the reverse

gap is '0", you should adjust it as the matter of fact.

c. You can choose "single -track light" when best laser engraving needed ,Not to choose the draw of "dual engrave",but when you choose it, the effciency would be lower.

6. The X-axis or the Y-axis not move.

a. Stir knob to chose the DC 5V, test the voltage between PULX (or PULY) and GND. Take Y axis as example, click the button of "up

or "down", the normal voltage is 2.8V, if it is not, we could confirm the controller was broken, please change the controller. If it is,

please go to next step.

b. Exchange the output terminal of the two drivers, then press "Up" or "Down" button; if X axis works normal, it means there is

something wrong with the motor on Y axis, please change a new one; if X axis doesn't work, it means there is something wrong with

the driver on Y axis, please chance it.

7. X Axis and Y Axis work in only one direction.

a. Test the voltage between the DIRX and GND after pressed the multimeter into grade 5V; take the X Axis for example, press "Ilft",

then press "right" to see if there is some change on high level (>2 8V) and the low level(<0 8V); if not, the control card is broken and

need to change a new one.

b. If with change, please check the driver, if works normal, please change the driver on Y Axis.

8.No Ray

Test the voltage between the LAS and GND after pressed the multimeter into grade 5V; press "fixed fire" in the control panel, to see if

there is some change on high level (<>2 .8V) and the low level(<0 8V); if not, the control card is broken and need to change a new one.

Also set up the time of fixed fir as 0 millisecond, which is in the PAD03 menu.

Adjust the power from 0%~100%, enter and press "fixed fire" button, then test if any change between the DA1 and GND from 0V to

5V; if not, the control card is broken, please change it, if both with, it means there is something wrong with the laser power supply.

1. CNC router spindle rotation sound is not normal

a. The drive is set incorrectly.

b. Check whether the cooling water circulation.

C. There are problems with the spindle (bearing damage).

d. If the noise when loaded knife, normal, replace the tool without tooling.

2. CNC router spindle hot or noisy:

a. Check whether the cooling water circulation.

b. Check whether the bearing problem.

C. If loaded knife noise, without tooling normal, replace the tool.

3. CNC router spindle cooling water does not flow:

a. Check the coolant pump is working properly.

b. Check whether the water flow, the water from the spindle joint apart, blowing to the other side of the steam gun from one side or the

connector on the spindle with a needle penetrating.

4. Motor reversal:

Check the motor cable is phase output UVW terminal ends of any exchange.

1. The machine and the computer must have a good grounding.

2. Open the cutting software, click the file menu, communication settings to receive and send the buffer time is changed to 5 or 10.

3. The replacement of the data line or motherboard.

According to the same direction of the panel button, the laser cutting machine appears to be turning and reversing and motor power

can not be locked.

1. First disconnect all power supply, the high pressure head with cotton cloth to wipe clean. (gentle scrub)

2. Cut off the broken pipe, re received the laser tube. And bundled with a tie.

3. The high voltage line (high pressure line with 7 silver thread, one less).

4. The fan will dry high pressure wet place, after half an hour, and then boot.

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining