+86 1525 3141 880

+86 1525 3141 880

HOME >> Support and Service >> CNC FAQs

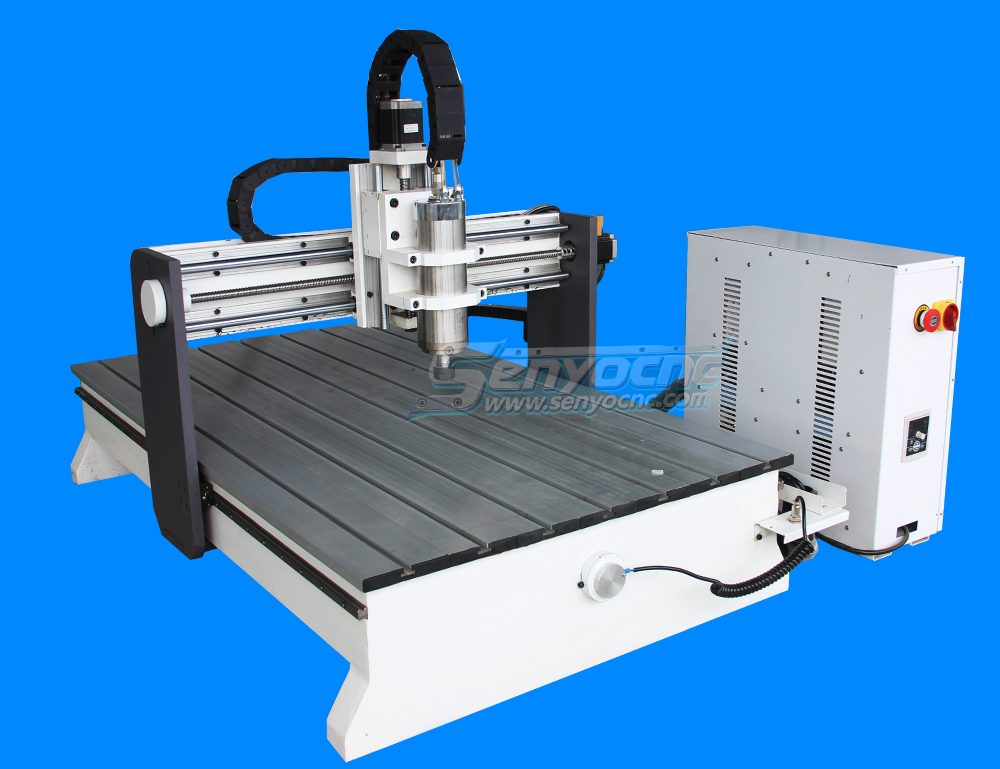

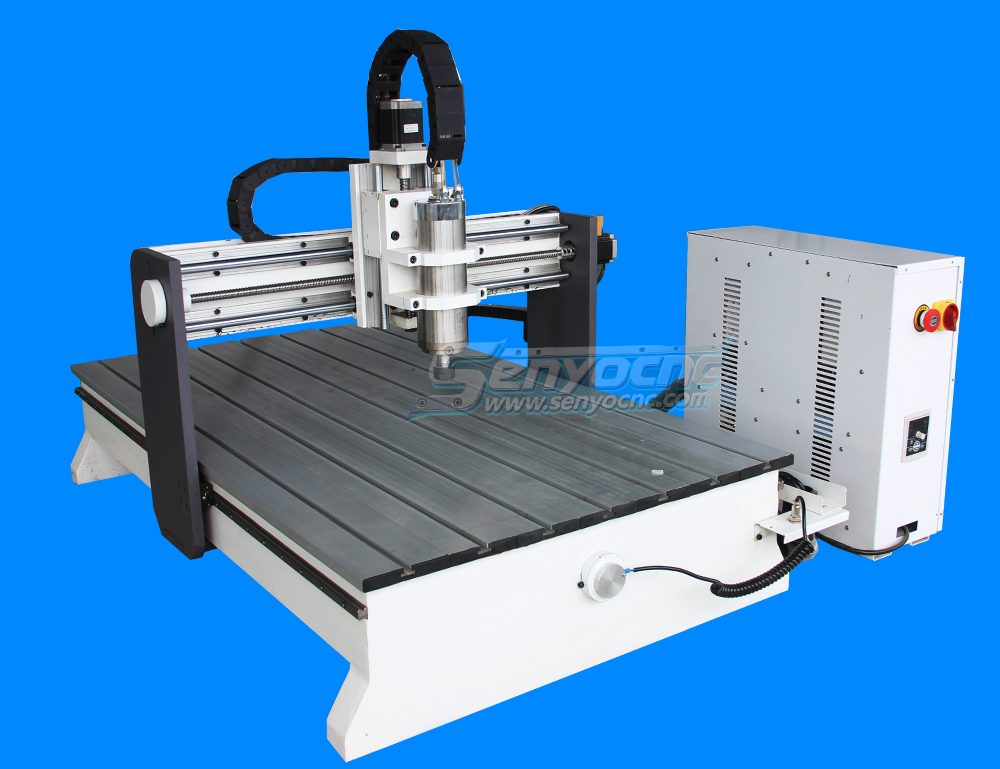

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

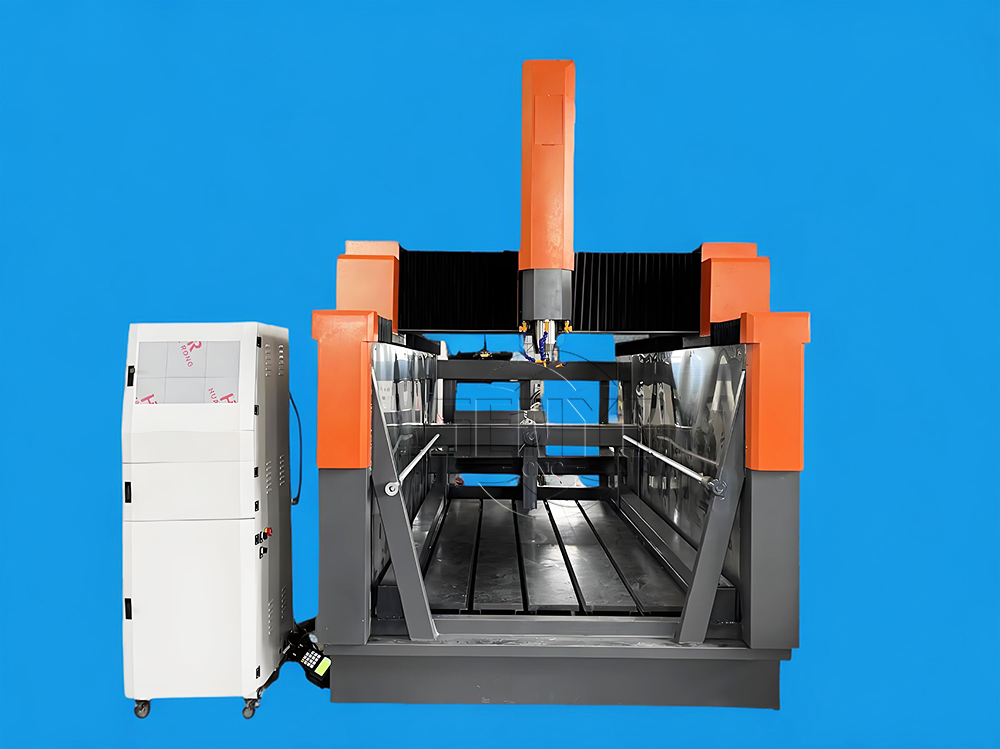

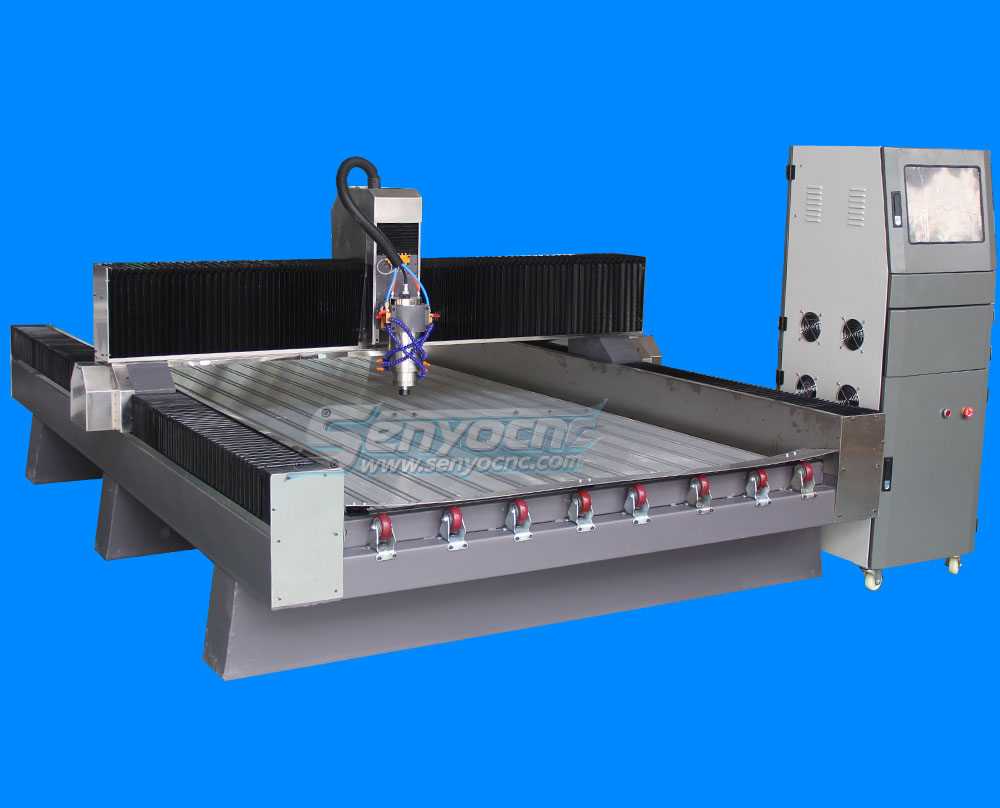

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining

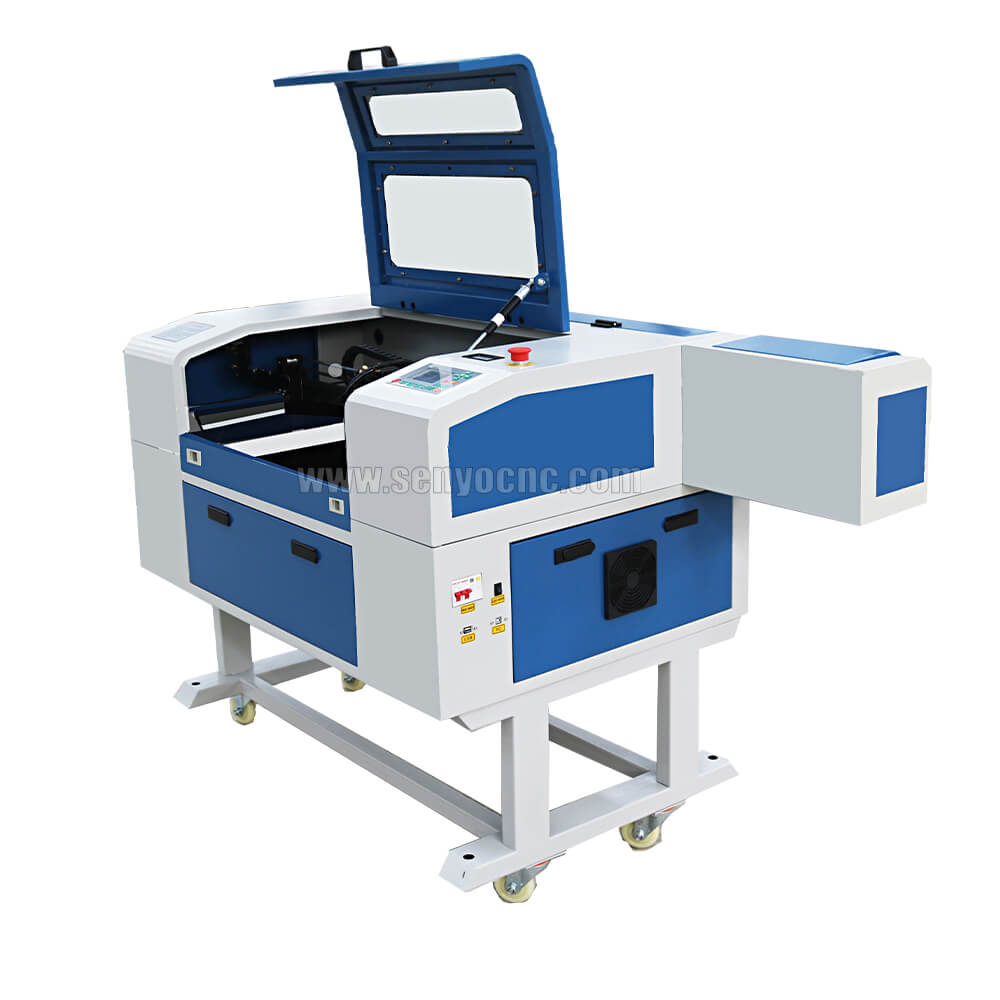

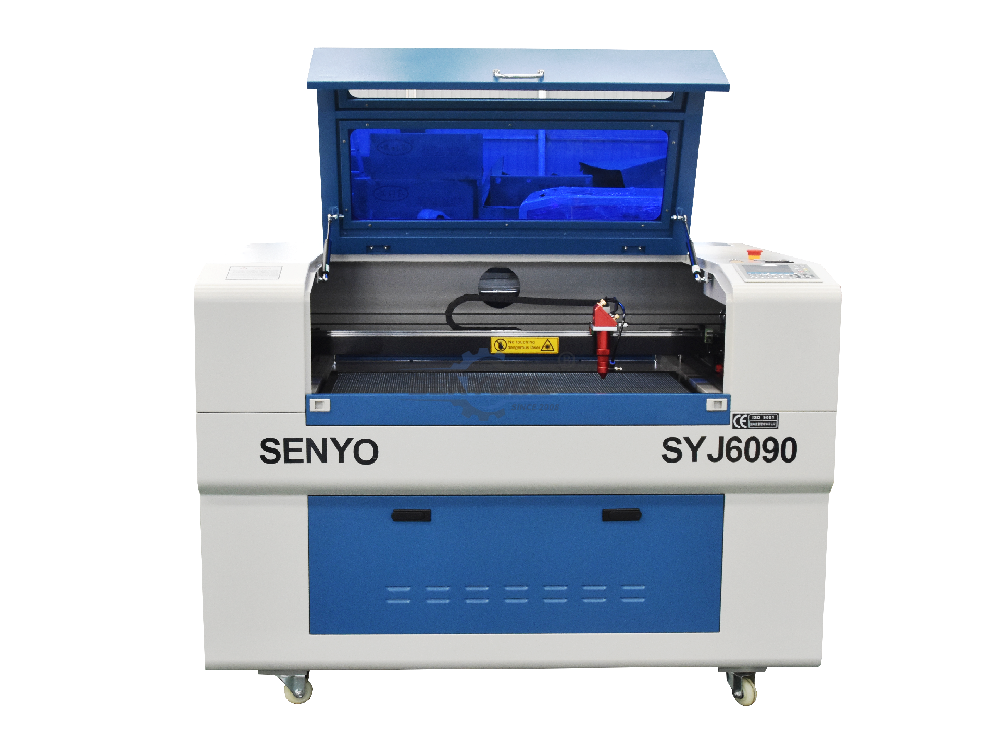

3020 40W Mini CO2 Laser Engraving Cutting Machine

New Design Mini Stone CNC Machine for Marble, Granite and Quartz

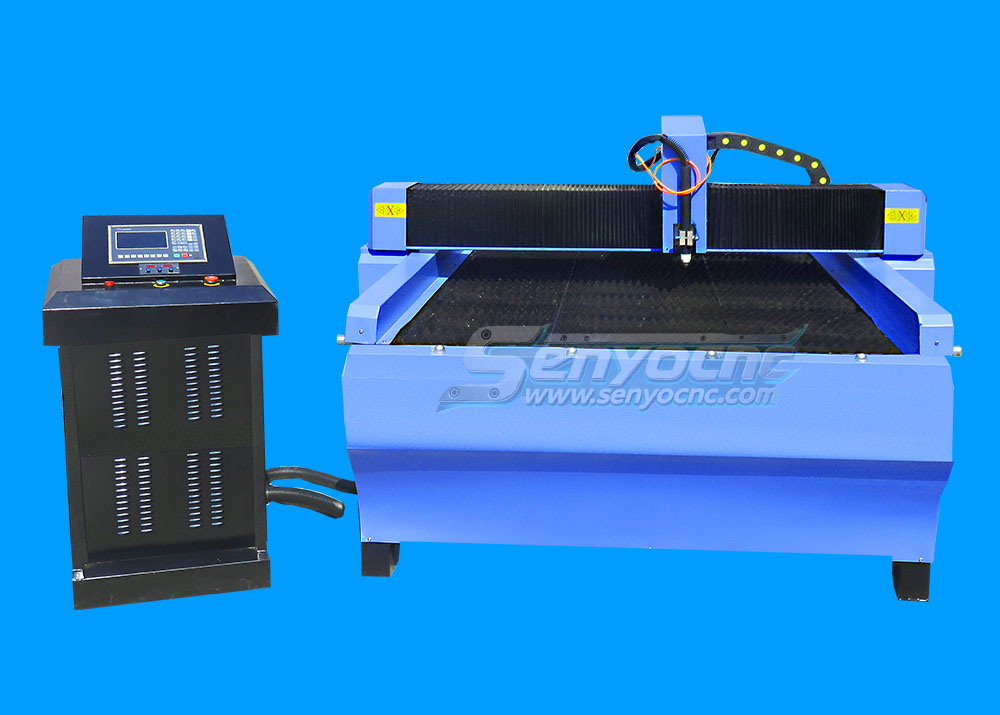

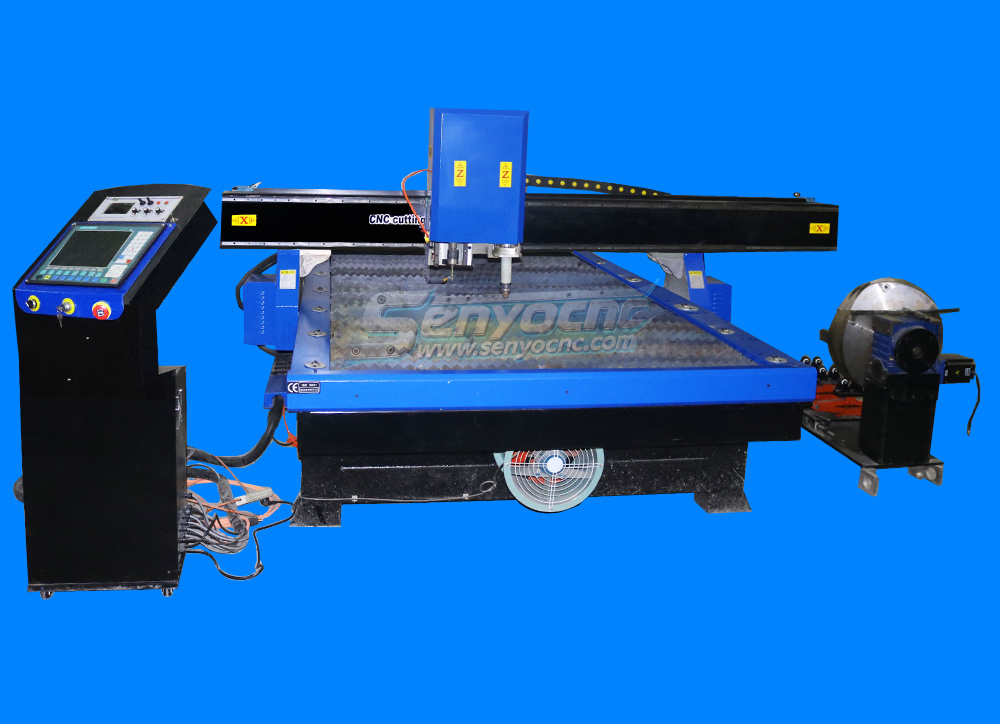

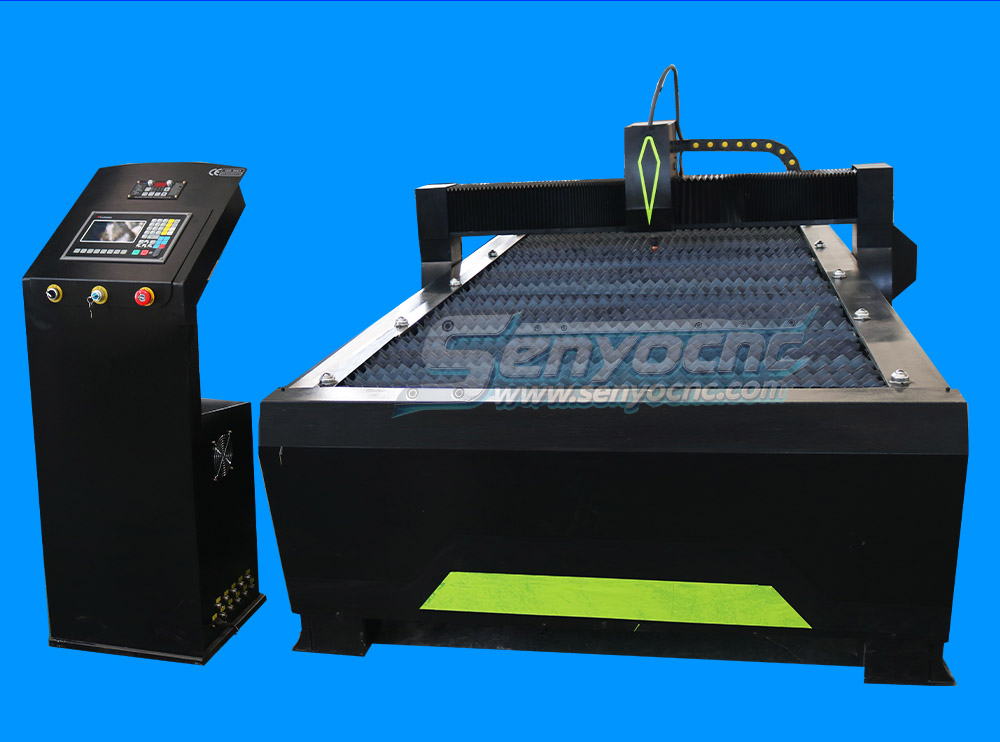

Portable CNC Flame Cutting Machine with Plasma Torch for Sale

High-Precision Mini Hobby CNC Plasma Cutting Machine for Metal

Mini CNC Plasma Cutter With Rotary

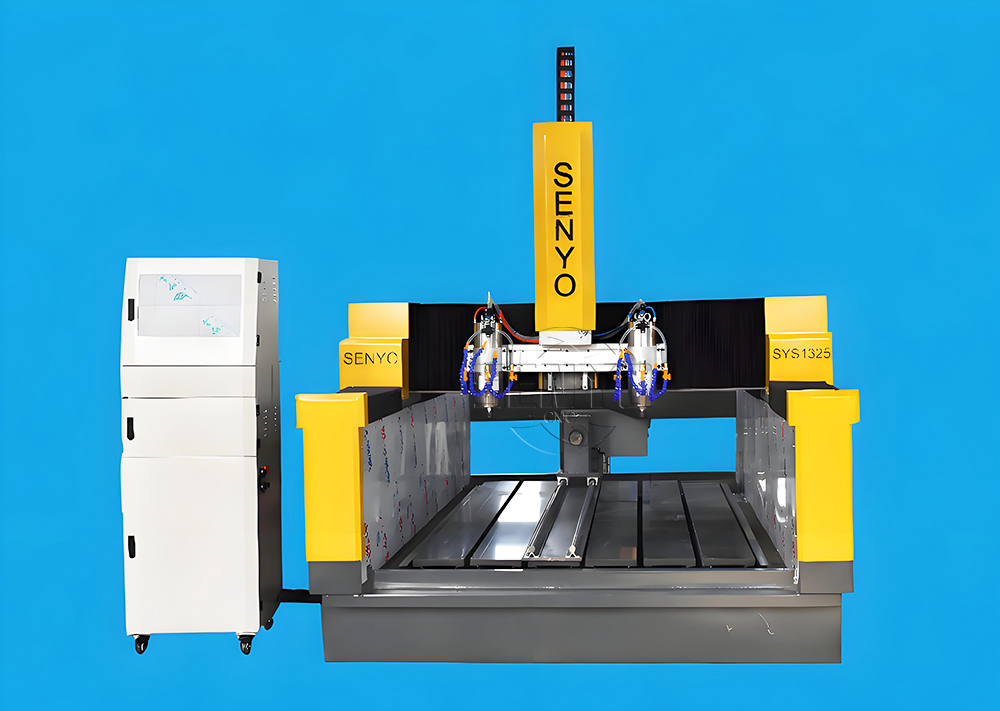

4 Axis 1325 Sculpture Machine Cnc Carving Marble Granite Stone Cnc Router

Z Height 1000MM 4-AXIS Stone Engraving CNC Machine Heavy-duty Stone CNC Machine Stone Relief Carving CNC For Sale

4030 portable mini co2 laser carving and desktop rubber stamp laser engraving machine

Stone CNC Router For Kitchen sink tile carving and cutting Marble, Granite and Quartz

Robust CNC Plasma Cutting Machines with Flame Cut Head for Heavy-Duty Industrial Use

Small Portable CO₂ Laser Cutter Engraving for DIY & Business – Ideal for Wood, Acrylic, Leather

1325 3 Axis 4x8 CNC Stone Router for Sale

Mini CO2 Laser 5030 Cutting Engraving Machine For Sale

Portable CNC Plasma Flame Cutting Machine for Sale at Cost Price

Portable Cnc Plasma Oxyfuel Sheet Metal Cutting Machine for sale

CNC Plasma Cutters for Customized Metalwork –Rotary&Drilling Head

Small Table design 6040 Easy Move CO2 Hobby Laser Cutter Machine for Beginners

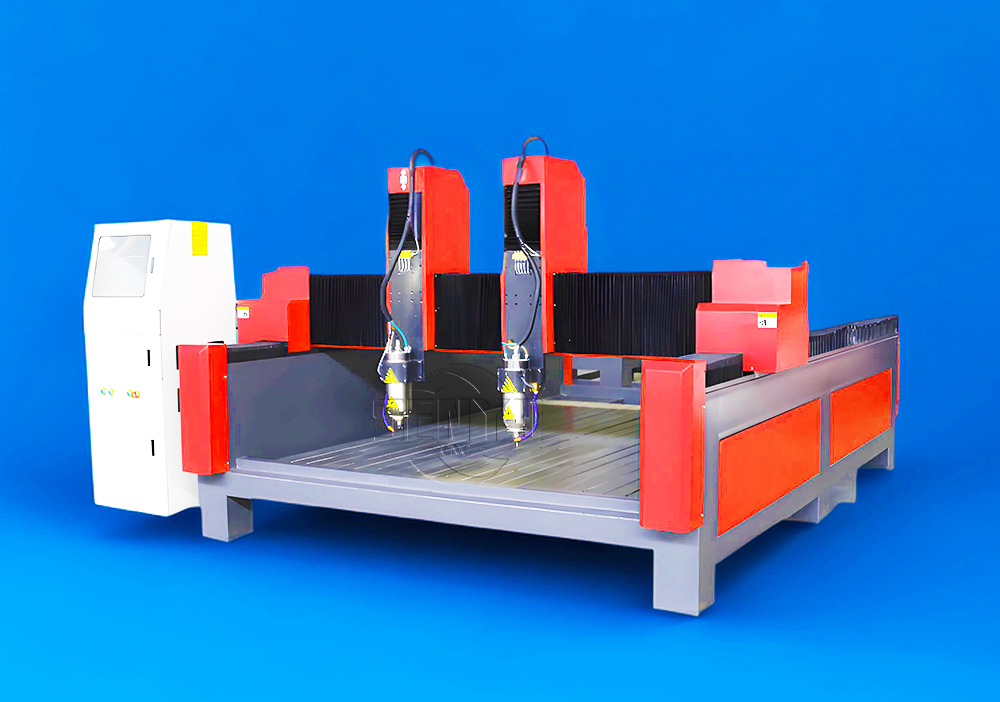

High-Efficiency 2 Heads CNC Machine for Aluminum Stone Marble Engraving & Cutting

Best CNC 2 Spindle 4-AXIS Stone Carving Machine High-precision Stone Carving Stone Countertop Fabrication

Top Rated 2x3 CO2 Hobby Laser Cutting Machine for Sale at Affordable Price

Best 4x8 CNC Plasma Cutter Table for Sale at Affordable Price

Entry Level CO2 Hobby Laser Cutter Machine for Beginners

Top CNC Plasma Cutters for Automotive, Aerospace, and Manufacturing Industries

Precision Stone Engraving Machines for Memorials & Signs

Portable Co2 9060 Laser Nonmetal Cutting Engraving Machine

1090 CO2 Laser Machine with Ruida Controller for Non-metal Glass Acrylic Engraving Cutting

Entry Level 9060 CO2 Hobby Laser Cutter Machine for Beginners

Aluminium machining, e.g. Machine parts, gears, components

Plastics Processing, e.g. Components for modelling / architectural modelling

Stainless steel processing, e.g. logos, emblems, trophies, inscriptions and initials for wind deflectors, tombstones and gravestones

Woodworking, e.g. 3D coat of arms, 3D wood reliefs, wooden toys, wooden signs, flaps, doors and candle arches, model components, etc.

Stoneworking, e.g. Gravestones, grave plates, ornaments, nameplates etc.

Increasingly popular are also applications in the field of 3D. So-called G-codes are sent to the machining centre using appropriate 3D CAD / CAM software. Due to the design of a portal milling machine, it is possible to use up to 6 axes: A, B, C and X, Y and Z, the A-, B- and C-axis represents a rotation around the axes X, Y and Z. Thus it is possible to mill in three dimensions and produce 3D statues, components and much more in a single step.

As individual as your wishes can be, the individual should be the advice you receive, because the more precisely your milling machine is tuned to key points, such as size, performance and workpiece to be machined, the better milling results you will receive later. An authorised dealer should also offer free support beyond the purchase, so entry is made easier and cheaper.

In terms of types of milling machines these differs by 2 points:

Location of the milling spindle

Horizontal milling machines

Vertical milling machines

Type of control

Mechanically controlled milling machines

Numerically controlled milling machines

In the field of CNC mills, the most common one is probably the portal milling machine.

The milling machine is often mentioned in connection with the abbreviation CNC. A CNC milling machine designates a computerised machine tool, lifting off material by rotating around a workpiece, and thereby giving it a predetermined shape.

Often small and large milling machines are used in the industrial sector. Due to the large variety of interchangeable tools, the CNC milling machine is to be found, increasingly, in the hobby sector.

You should ask yourself the following questions before buying a CNC mill:

What type of material do I want to process and how hard is it regarding the engine power of the milling motor? Hard or soft? Heat sensitive?

What are the maximum sizes of my workpieces concerning the size of my desired milling machine?

Which quantities do I want to manufacture in one operation?

How exactly do the features of my chosen portal milling machine match the needs of my workpiece to be processed?

Do I get expert support even after purchasing, possibly even free?

The more precisely you can define the requirements of the desired machine before buying, the more accurate a competent seller can offer the right machine, and then the more precise the milling results will be achieved. In a professional, experienced company, you will always have a trained technician and/or seller.

paper and pencil, happens today, with much less effort, using a PC. Thanks to modern CAD (Computer-aided design) / CAM (Computer-aided manufacturing) control software, it is possible to send data sets, usually called DIN ISO G-codes, of almost any shape, whether 2D or 3D, to the machine. The machine then works row by row, until the workpiece has been processed as desired. Ready is your customized workpiece. Because also here applies:

The better all components are matched to one another, the more efficient and accurate a CNC mill will work!

A CNC mill describes as the name indicates, a particular building type of a milling machine. Here, the X-axis is arranged horizontal, the Y-axis vertical, and the Z-axis perpendicular on the two other axes, which together results in a so-called portal. Some portal milling machines have multiple milling heads on the Z-axis, in addition to the milling head on the Y-bridge, to allow simultaneous processing of all sides in one step.

The workpiece to be machined is either mounted on a movable clamping table which moves within the portal in accordance with the desired material to be removed, or on a stationary clamping table which is travelled by the sled of the milling machine.

On closer examination of the CNC sector and related milling machines, we find the CNC mill is very popular. This fact encouraged us to answer some questions regarding portal milling machines:

What is a CNC mill?

What is this machine type used for?

Which software is suitable for working with a milling machine?

Which points are important when buying a CNC controlled mill?

The standard equipment also includes the ergonomic operating terminal with an industrial PC with touch display and integrated control. Accordingly, you can work either directly on the touch display or very conveniently with the wireless keyboard and mouse included in the scope of delivery at a comfortable height on the control panel. Due to the sloping design of the terminal, the Full-HD 1920 x 1080 screen is optimally visible and accessible.

The optionally selectable dust extraction system operates pneumatically and keeps the work surface free of dust and chips during the work process. The suction shoe can be lowered and raised again by using the toggle switch on the control panel. An all-round brush strip surrounds the suction shoe and can therefore adapt to any shape of the workpiece.

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining