+86 1525 3141 880

+86 1525 3141 880

HOME >> Support and Service >> CNC FAQs

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining

3020 40W Mini CO2 Laser Engraving Cutting Machine

New Design Mini Stone CNC Machine for Marble, Granite and Quartz

Portable CNC Flame Cutting Machine with Plasma Torch for Sale

High-Precision Mini Hobby CNC Plasma Cutting Machine for Metal

Mini CNC Plasma Cutter With Rotary

4 Axis 1325 Sculpture Machine Cnc Carving Marble Granite Stone Cnc Router

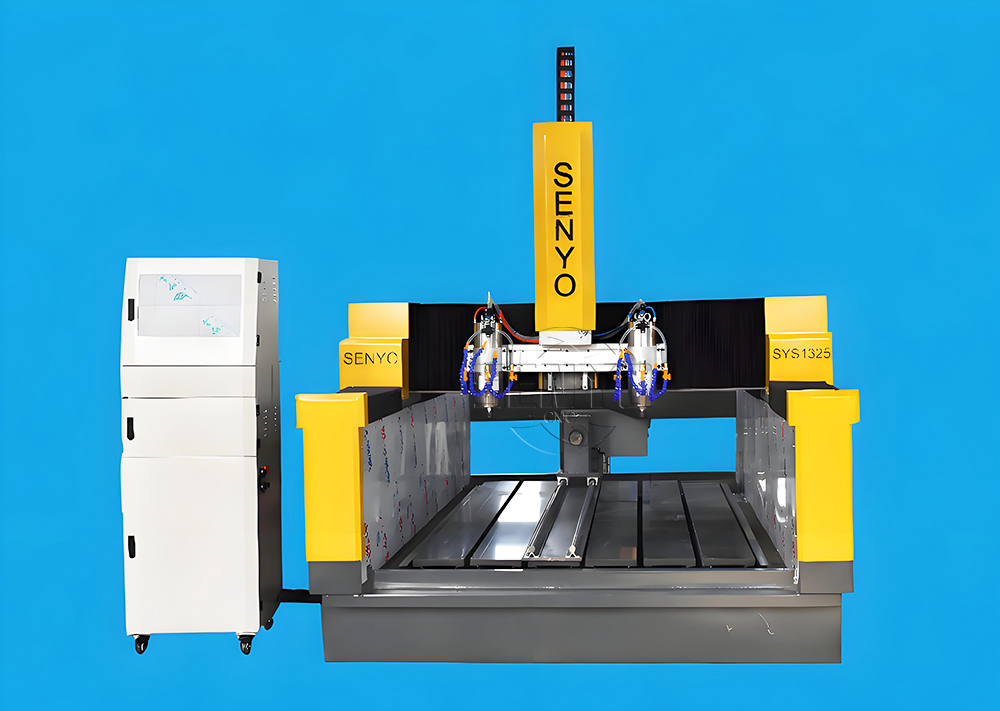

Z Height 1000MM 4-AXIS Stone Engraving CNC Machine Heavy-duty Stone CNC Machine Stone Relief Carving CNC For Sale

4030 portable mini co2 laser carving and desktop rubber stamp laser engraving machine

Stone CNC Router For Kitchen sink tile carving and cutting Marble, Granite and Quartz

Robust CNC Plasma Cutting Machines with Flame Cut Head for Heavy-Duty Industrial Use

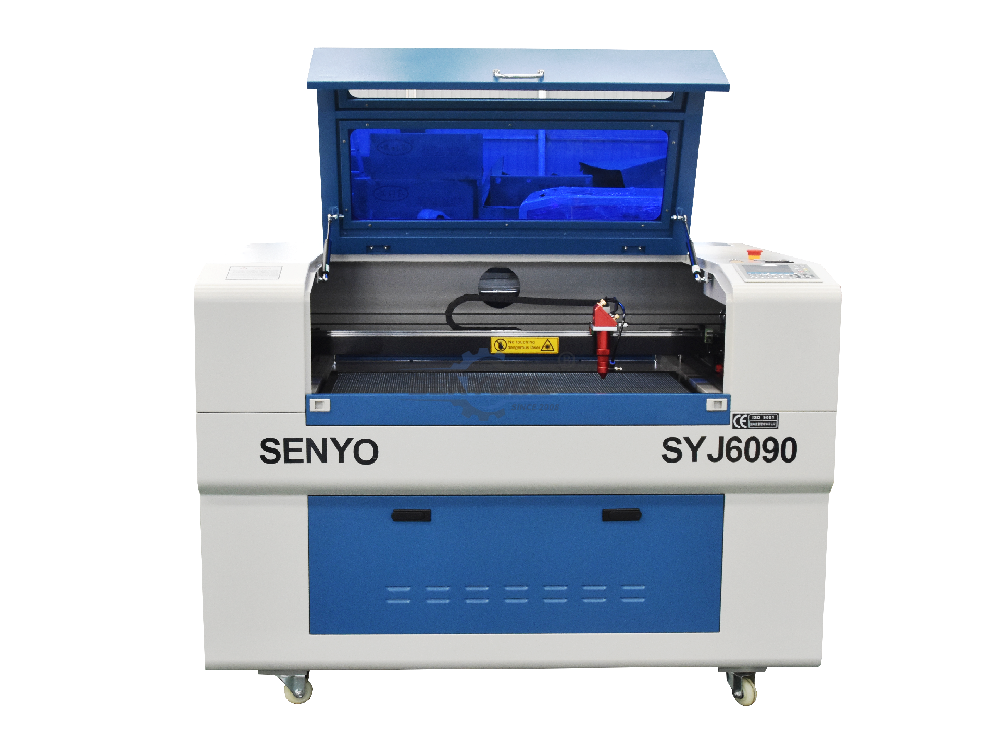

Small Portable CO₂ Laser Cutter Engraving for DIY & Business – Ideal for Wood, Acrylic, Leather

1325 3 Axis 4x8 CNC Stone Router for Sale

Mini CO2 Laser 5030 Cutting Engraving Machine For Sale

Portable CNC Plasma Flame Cutting Machine for Sale at Cost Price

Portable Cnc Plasma Oxyfuel Sheet Metal Cutting Machine for sale

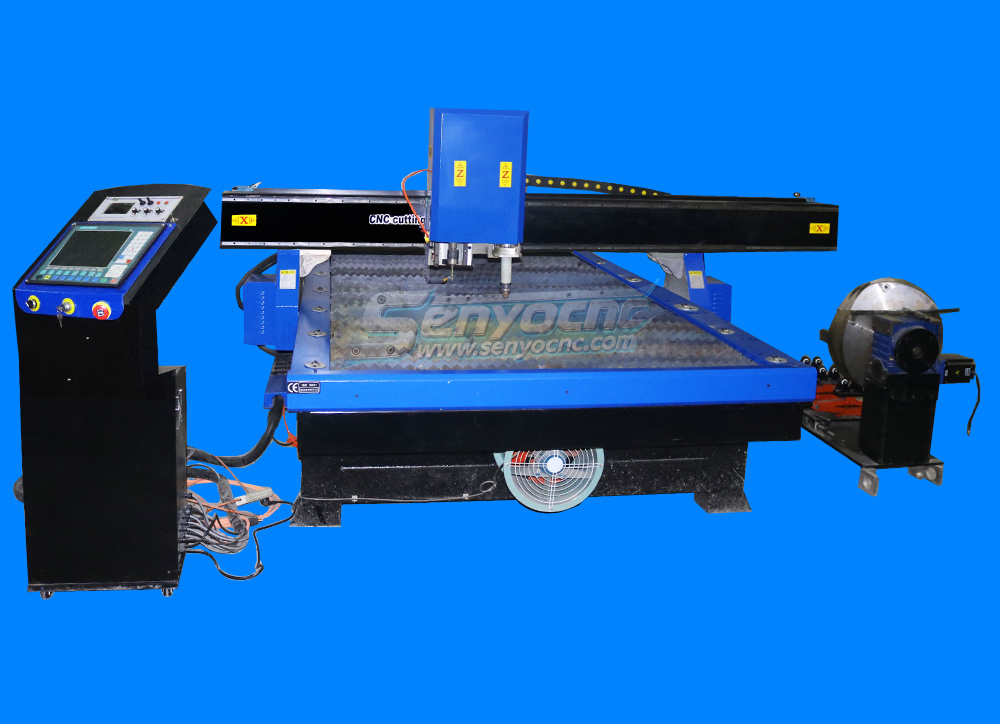

CNC Plasma Cutters for Customized Metalwork –Rotary&Drilling Head

Small Table design 6040 Easy Move CO2 Hobby Laser Cutter Machine for Beginners

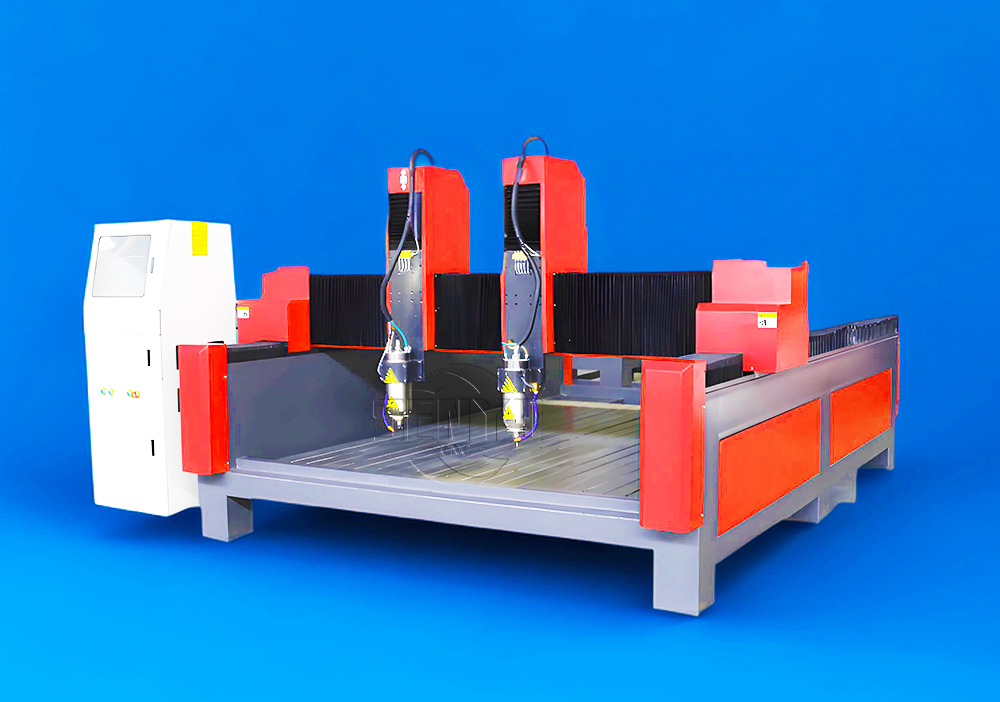

High-Efficiency 2 Heads CNC Machine for Aluminum Stone Marble Engraving & Cutting

Best CNC 2 Spindle 4-AXIS Stone Carving Machine High-precision Stone Carving Stone Countertop Fabrication

Top Rated 2x3 CO2 Hobby Laser Cutting Machine for Sale at Affordable Price

Best 4x8 CNC Plasma Cutter Table for Sale at Affordable Price

Entry Level CO2 Hobby Laser Cutter Machine for Beginners

Top CNC Plasma Cutters for Automotive, Aerospace, and Manufacturing Industries

Precision Stone Engraving Machines for Memorials & Signs

Portable Co2 9060 Laser Nonmetal Cutting Engraving Machine

1090 CO2 Laser Machine with Ruida Controller for Non-metal Glass Acrylic Engraving Cutting

Entry Level 9060 CO2 Hobby Laser Cutter Machine for Beginners

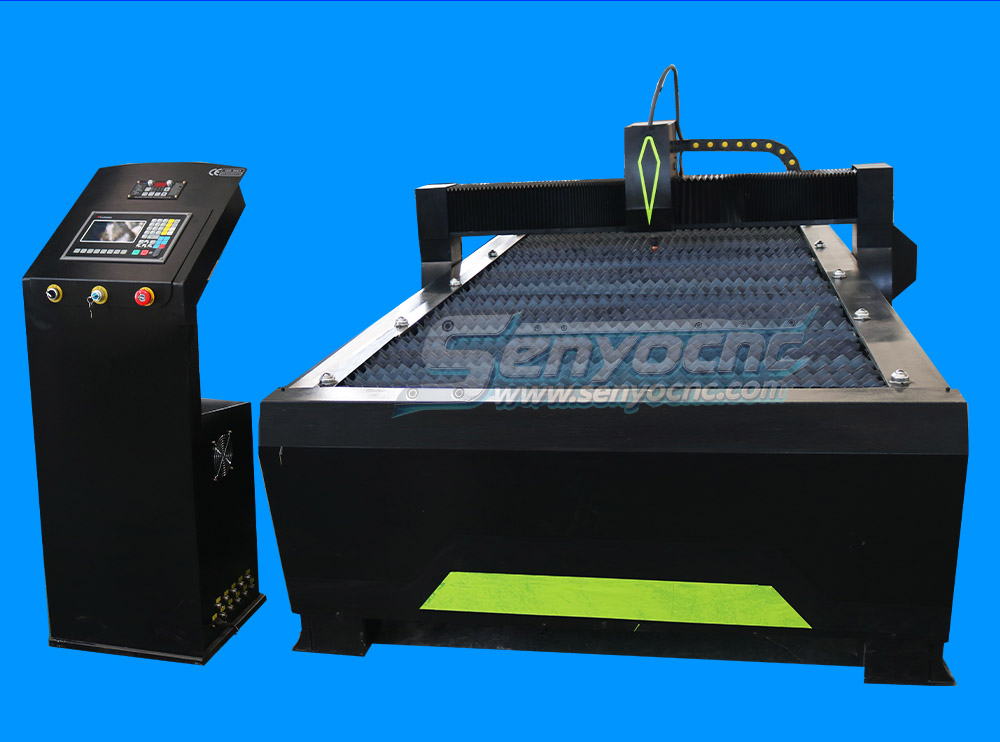

CNC Plasma cutters are an efficient metal cutting method for sheet metal and metal tubes, which has made it to be widely used in many different industries. You can get benefits from 10 best advantages with fast cuts, ease of use, lower cost, safe to use, multi-tasking, expanded versatility, wide range of material and thickness, eliminated plate warping, raised inside piercing speed, and diminished dross. Compared with traditional semi-automatic and manual cutting method, automatic CNC metal cutter has greatly improved the efficiency and quality. CNC metal cutting system is an exponentially controlled plasma, flame, water jet and laser cutting machine. It performs automatic, full-time, high-quality, high-utilization and efficient cutting according to the CNC nesting software. In industrial production, metal thermal cutting generally includes gas cutting, plasma cutting, and laser cutting.

Compared with gas cutting, plasma cutting has a wider cutting range and higher efficiency. The fine plasma cutting technology is close to the quality of laser cutting in terms of the cutting surface quality of the material, but the cost is much lower than that of laser cutting. It has shown great advantages in saving materials and improving labor productivity. This has promoted the development of plasma cutting technology from manual or semi-automatic to numerical control, and has become one of the main directions of the development of numerical control cutting technology.

It can cut thicker metals, such as stainless steel, aluminum and its alloys, copper and its alloys, cast iron and other metal materials. You can also use a non-transferred plasma arc cutting gun to cut non-conductive non-metallic materials and insulating materials with a cutting thickness of more than 150mm.

The cutting speed is fast, and the production efficiency is high, especially when cutting thin metals with high power, the production efficiency is improved more significantly.

The cutting quality is high, the slit is smooth and flat, the incision is narrow, and the heat-affected zone and deformation are smaller than other cutting methods.

Low

cost, due to the high speed, the use of cheap gas such as nitrogen

requires less raw materials and labor than other methods to cut the same

material.

Plasma CNC cutters are used for cutting sheet metals, square and round metal tubes, including iron, cold rolled steel, hot rolled steel, stainless steel, galvanized steel, carbon steel, copper, brass, alloy, bronze, aluminum, titanium. Plasma cutting machines are widely used in the industries of machine tool manufacturing, petro-chemical equipment, light-industrial machinery, pressure vessel, shipbuilding, mining machinery, electric power, bridge construction, aerospace, steel structure, etc. Plasma cutters can be applied to hobbyists, home shop, home business, small shop, small business, school education, industrial manufacturing.

Plasma cutting is a machining method that

uses the heat of a high-temperature plasma arc to melt at a metal

workpiece, and to eliminate the molten metal by high-speed plasma

momentum to create a slit. Plasma cutters send an electric arc by using

gas like oxygen, nitrogen or compressed air. This turns the gas to

plasma, as well as it promptly blasts through metal to cut it with

broadband. A flame cutting torch works by adding a blast of oxygen to

the flame which oxidizes the metal and turns it into slag. The plasma

torch moves with a tool path directed by a computer. The term “CNC”

means “Computer Numerical Control”, which implies that a computer is

used to control the motion supported G-code in a program. Compared to

handheld plasma cutters, plasma CNC cutters realize automatic machining

with high efficiency, high speed, and high quality.

CNC plasma table is a type of plasma CNC

cutter with custom welding workbench table top, which can be well adapt

to cut metal projects with different sizes. There are slide rails on

both sides of the workbench table frame, and the cutting mounting seat

is slidably connected to the two slide rails above the workbench frame.

The cutting mounting seat is slidably connected with cutting components.

The workbench frame includes a sink and multiple supports column, both

sides of the sink are fixedly provided with flanges, and a pressing

structure is installed at the flanges. The pressing structure includes a

pressing plate arranged above the supporting column and a pressing

assembly connected to the flange position. The pressing assembly

includes a rotating The screw rod connected to the flange and the

compression ring threadedly connected to the screw rod, the screw rod

passes through the compression plate, and the compression plate is

located below the compression ring on the screw rod. A pressing

mechanism is set on the workbench table frame. After the plate is placed

on the workbench frame, the pressing ring is rotated to make the

pressing plate compress the plate on the workbench frame, which can

flatten the plate with poor flatness and tendency to roll, saving the

labor of sheet metal fabrication, and the cutting is more convenient and

safe.

CNC plasma cutter is a type of computer

numerical controlled metal cutting machine with CNC controller that

adopts plasma torch to cut different metals into different profiles and

shapes, including mild steel, stainless steel, carbon steel, galvanized

steel, hot rolled steel, cold rolled steel, iron, brass, copper, alloy,

aluminum, bronze, titanium. A CNC plasma kit is composed of machine

frame, plasma CNC controller, plasma power supply, plasma torch, blade

or sawtooth plasma table, driver, motor, plasma CNC cutting system,

harbor freight tools (harbor freight generator, harbor freight air

compressor parts – pump and motor), plasma CNC cutting software, guide

rail, ball screw, optional parts and consumble parts. CNC plasma cutter

is also known as plasma CNC cutter, CNC plasma table, CNC plasma cutting

machine, CNC plasma cutting table, CNC flame cutting machine, CNC

oxy-fuel gas cutting machine, CNC flame plasma cutting machine, CNC oxy

fuel cutting machine, CNC plasma & oxy-fuel cutting machine.

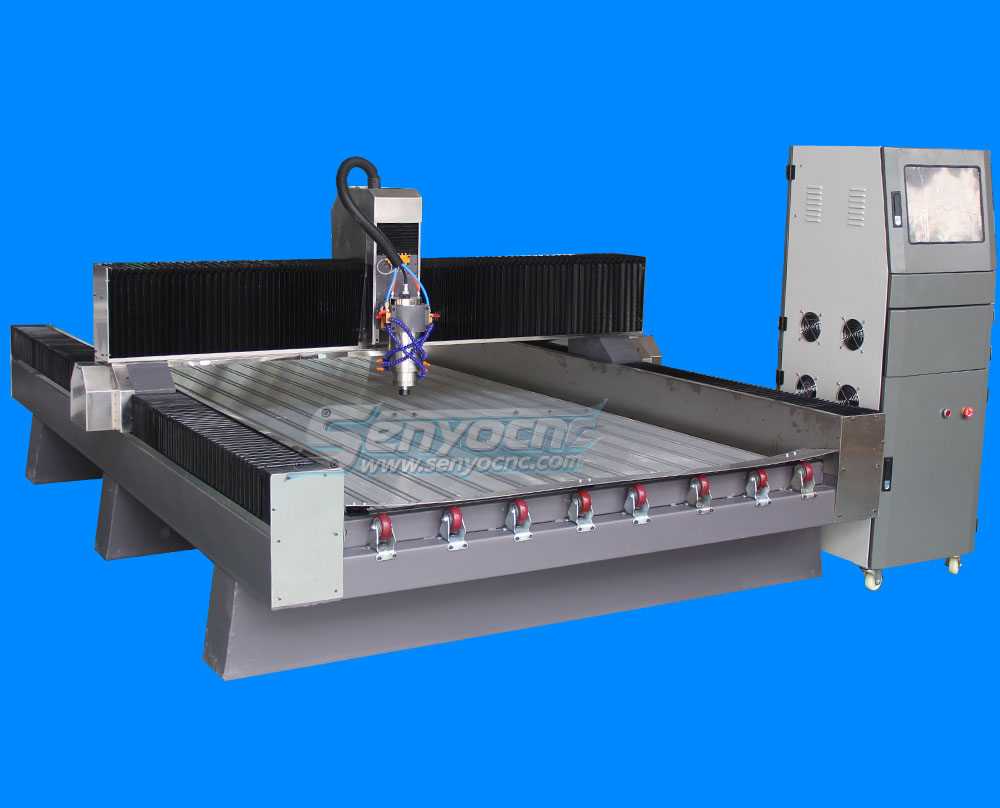

Stone machine CNC is a machine tool with computer number controlled for stone machining. A stone machine CNC is

also known as CNC stone carving machine, CNC stone engraving machine,

CNC stone cutting machine, stone CNC router or CNC stone router. Stone

CNC machines have functions of carving, engraving, cutting and polishing

for marble, granite, artificial stone, tombstone, ceramic tiles.

Types of Table: 2×3 CNC wood router

tables, 2×4 CNC wood router tables, 4×4 CNC wood router tables, 4×6 CNC

wood router tables, 4×8 CNC wood router tables, 5×10 CNC wood router

tables, 6×12 CNC wood router tables. Types of Application: Home wood CNC

machines, Desktop wood CNC machines, 3D wood CNC machines, Hobby wood

CNC machines, Industrial wood CNC machines. Types of Axis: 3 axis CNC

wood routers, rotary axis CNC wood routers, 4th axis CNC wood routers, 4

axis CNC wood routers, 5 axis CNC wood routers.

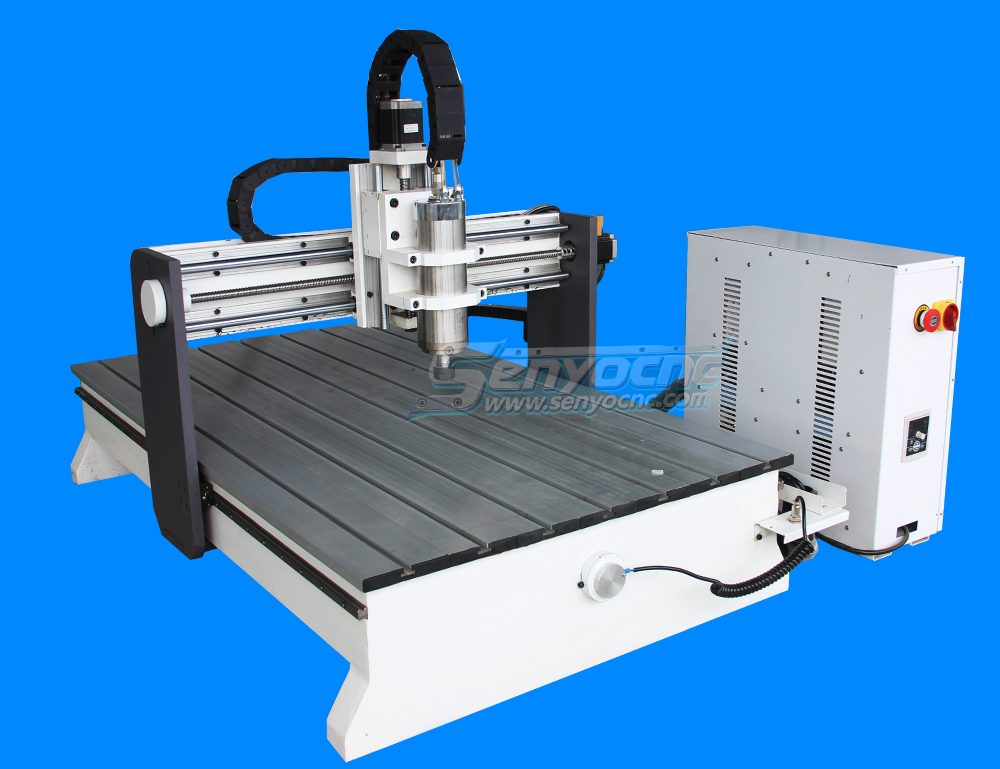

The woodworking CNC machine adopts a

computer to realize digital program control, and executes the control

program stored in advance through the computer to realize the machine’s

motion control, timing, logic and other functions, so as to control the

equipment to complete the automatic woodworking.

Wood CNC Machine is a type of CNC wood router with

Computer Numerical Controlled for smart 2D/3D cutting, carving,

routing, milling, drilling and grooving on most popular woodworking,

including wood crafts, wood arts, wood signs making, cabinet making,

wood door making, wood gifts, wood toys, wood modeling, decorations,

wardrobe and other wood furniture making. A CNC wood router is composed

of CNC controller, machine frame, gantry, spindles, CNC operating

system, CNC software, driver, motor, ball screw, guide rail, T-slot

table or vacuum table, vacuum pump, power supply, limit switch, collet,

rack and pinion. A CNC wood router is also known as wood CNC machine,

wood CNC router, CNC woodworking router, woodworking CNC router,

woodworking CNC machine, wood CNC carver, wood CNC engraver, wood CNC

cutter, wood CNC table, CNC wood machine, CNC wood table, CNC wood

engraver, CNC wood carver, CNC wood cutter, CNC wood routing machine,

CNC wood carving machine, CNC wood cutting machine, CNC woodworking

machine, CNC router for woodworking, CNC woodworking tool.

(1). Industries:

Building Industry (General Woodworking, Kitchen Cabinet & Door, Facades & Curtainwall, Column & Balustrade)

Sign & Advertising (Signage Indoor & Outdoor, Engraving& Bas-Relief, 3D Letters, Funeral)

Models & Prototyping

Plastics & Composites (ACP, ACM and solid surface material etc)

Non-ferrous metals & Marine

(2). Material:

Wood: Plywood, Soft Wood, Hard Wood, MDF, Chipboard

Plastic: Acrylic, ABS, HDPE, PVC, UHMW, HDPE

Stone: Granite, Marble, Slate, Basalt, Pebbles, Natural Stone, Ceramic, Porcelain

Metal: Aluminium, Brass, Copper, Mild Steel, Stainless Steel

Composite: Aluminium Composite, Copper Composite, Titanium Composite, Zinc Composite.

Mini Desktop CNC Router for Gifts Making Small Business

Best Granite marble manual polishing machine For Sale

Stone Processing CNC Equipment Automatic Tool Changer CNC Quartz Stone Machining