How to get started with laser cutting in 4 steps

From: 本站 Date: 03rd September 2021 Author: shengangtong Views: 3281

Here’s a step-by-step overview of what you need to consider to make it happen.

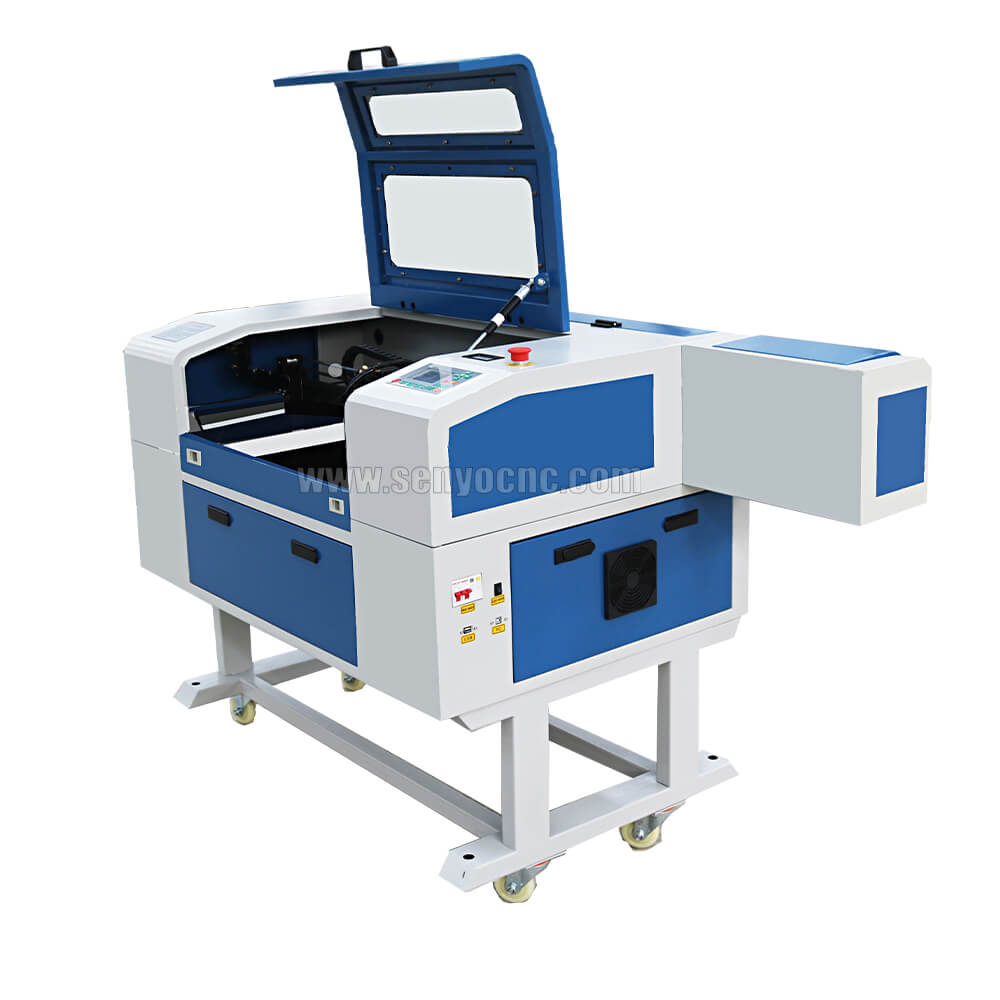

1. Get access to a laser cutter

2. Choose a material to cut or engrave

3. Create your design

4. Cut or engrave it

1.There are a lot of other options to get access to a laser cutter:

Makerspaces

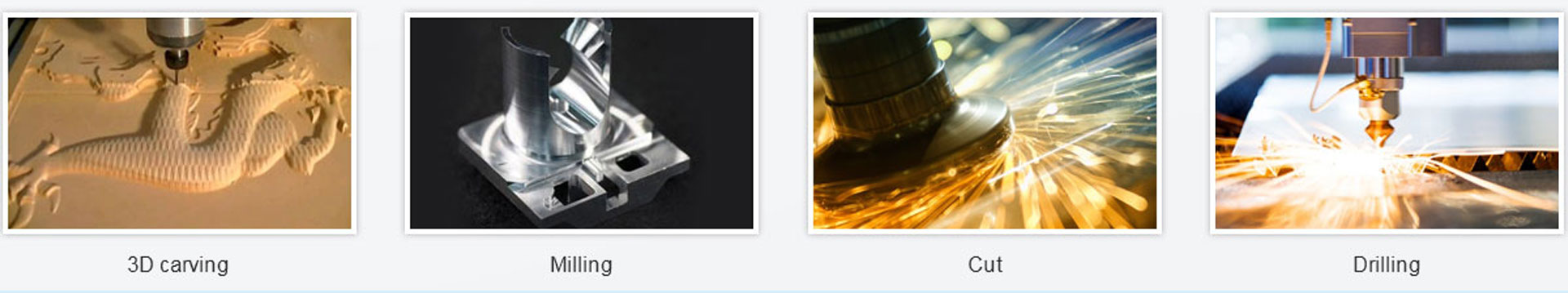

If you are interested in getting some hands-on experience with a laser cutter, I recommend looking for a local makerspace. Makerspaces – sometimes also called maker lab or hackerspace – are collaborative work spaces for making and learning. They offer a variety of equipment like for example 3D printers, CNC machines, soldering irons and very often also laser cutters!

Schools, colleges and universities

Especially if you are a student, schools, colleges and universities are also a good place to look for a laser cutter.

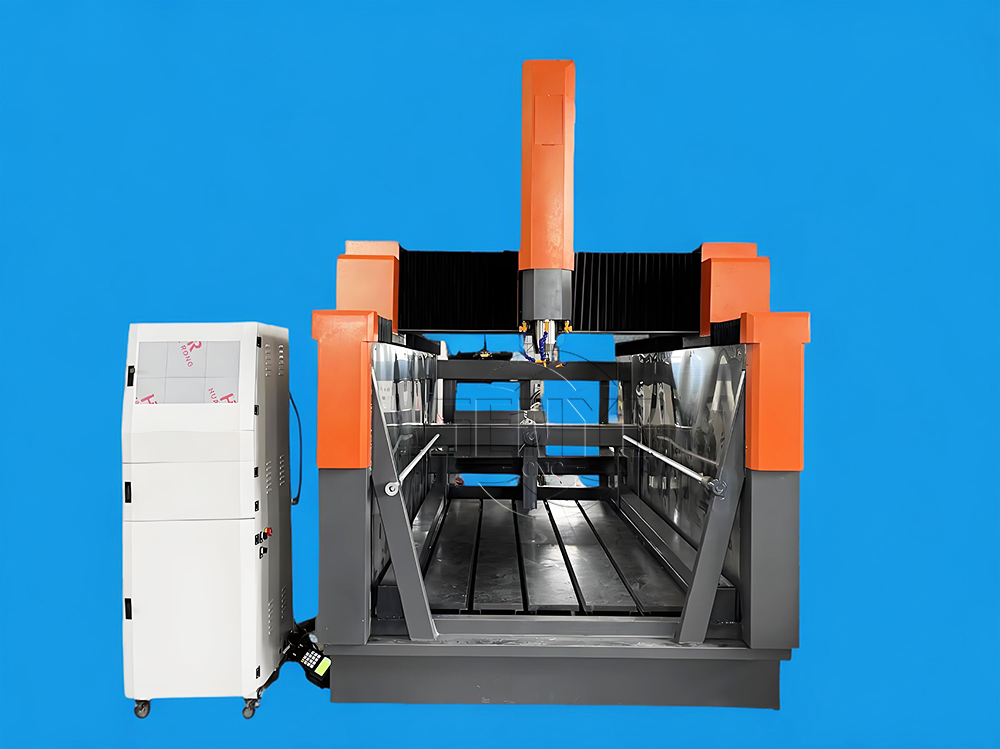

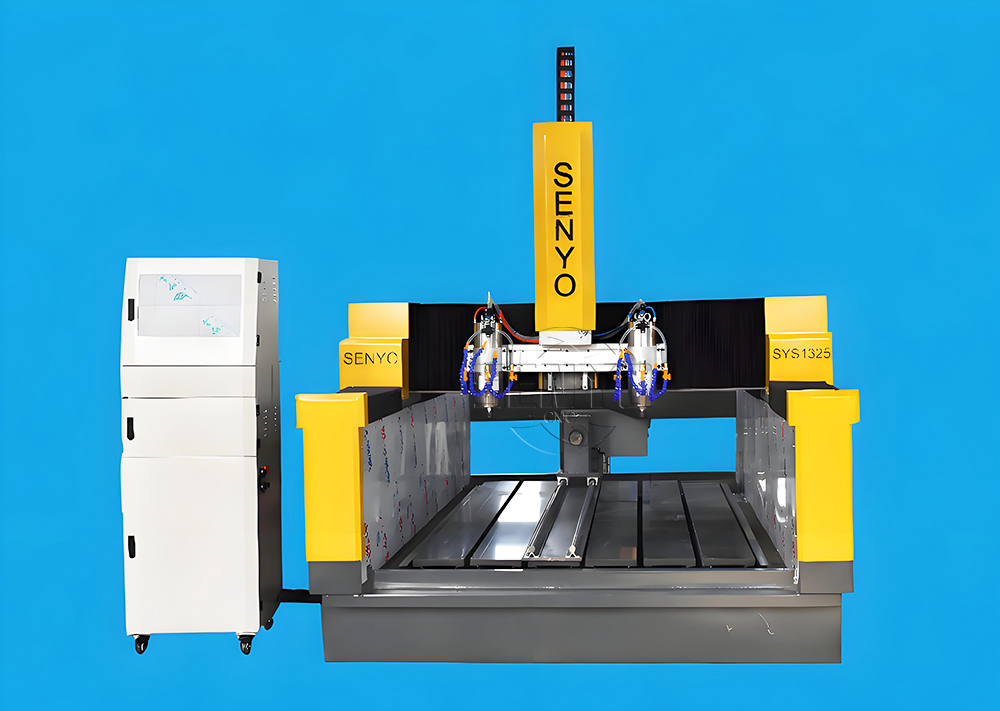

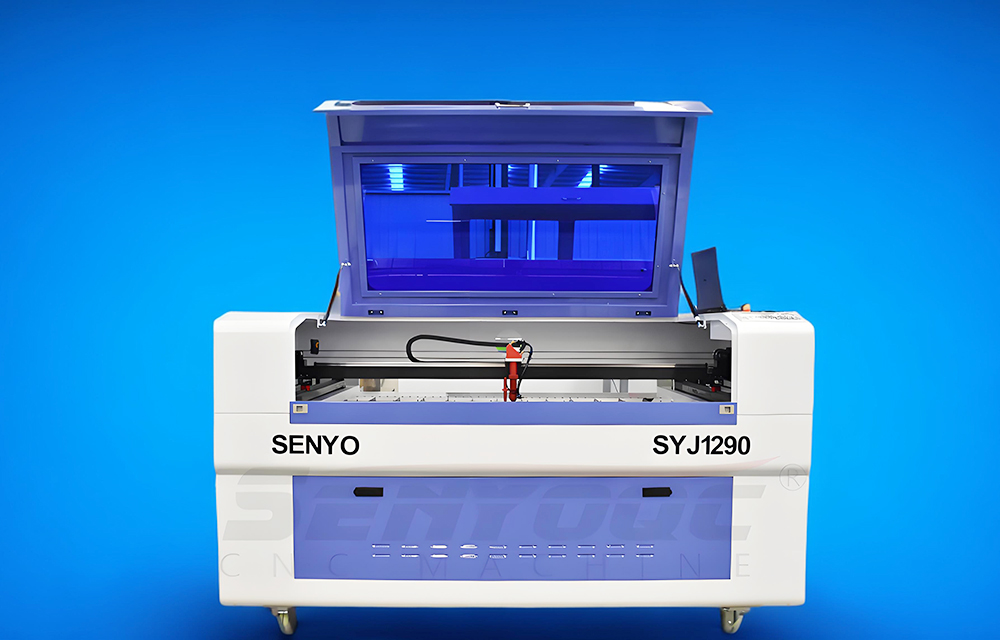

Buying a Laser Cutter

If you are just starting with laser cutting I recommend trying one of the options above before looking into buying a laser cutter to get some experience and find out which features are most important for you

2. What materials can be cut or engraved with a laser?

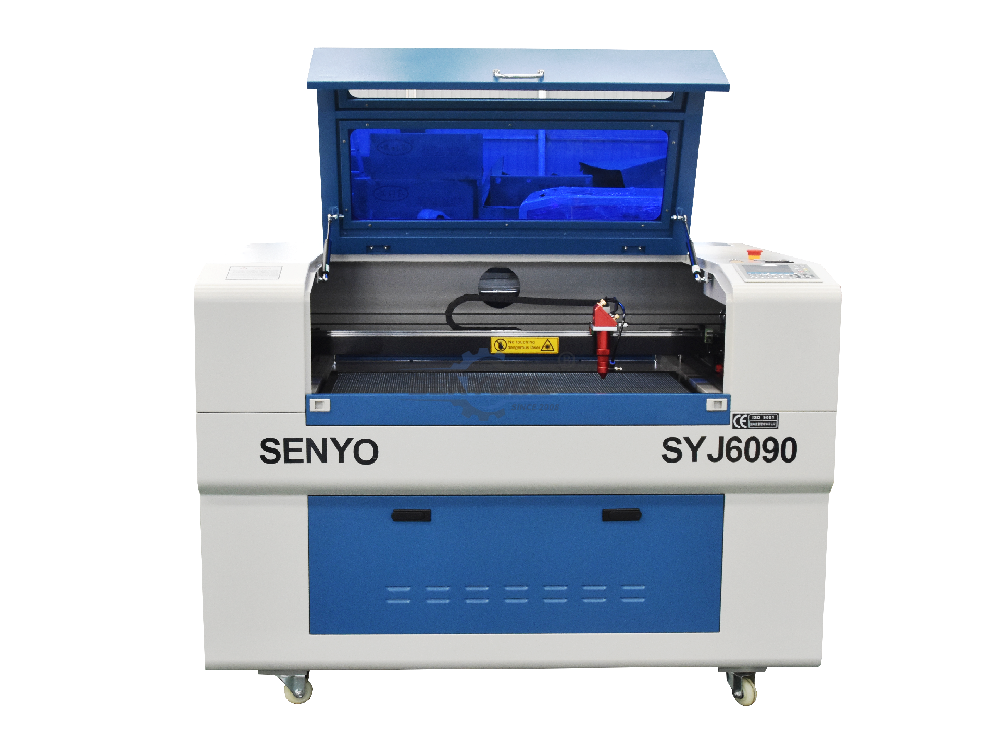

CO2 laser machines are capable of cutting and engraving a variety of materials. However, there are also materials which cannot be processed. This may be because the laser can not cut through the material, or because toxic gases would form. Also, very flammable materials cannot be used.

Depending on the power and other specifications of the machine you are using, the maximal material thickness that can be cut will vary. The power of laser cutters is measured in Watt. Typical power levels range between 30 Watt and 300 Watt. Lasers with higher power are mostly used in industrial applications only.

| Material | Cut | Engrave | Comment |

Wood | yes | yes | |

| Plywood | yes | yes | Lasers can struggle to cut plywood sheets with exterior glue. Use plywood with interior glue. |

| MDF | yes | yes | |

| Cork | yes | yes | |

| Cardboard | yes | yes | |

| Paper | yes | yes | |

| Leather | yes | yes | Use vegetable-tanned for best results |

| Felt | yes | yes | |

| Cotton | yes | yes | |

| Acrylic (Plexiglas) | yes | yes | |

| Delrin (POM, acetal) | yes | yes | |

| High-density polyethylene (HDPE) | yes | yes | Edges melt badly. Watch closely – easily catches fire. |

| Polypropylene (PP) | yes | yes | Melts somewhat |

| Granite | yes | ||

| Marble | yes | ||

| Slate | yes | ||

| Stone tiles | yes | ||

| Ceramic, Porcelain | yes | ||

| Glass | yes | ||

| Stainless Steel | yes | Can be marked | |

| Aluminum | yes | Can be marked |

Materials that should not be cut or engraved with a laser

There are materials that should never be processed with a laser because this will lead to the creation of toxic gases or dust which can also damage the machine.

These materials include (but are not limited to):

Leather and artificial leather that contains chromium (VI)

Carbon fibers (Carbon)

Polyvinyl chloride (PVC)

Polyvinyl butyrale (PVB)

Polytetrafluoroethylenes (PTFE /Teflon)

Beryllium oxide

Any material containing halogens (fluorine, chlorine, bromine, iodine and astatine), epoxy or phenolic resins

3. How to create a design for laser cutting or engraving?

Most CO2 laser cutters work very much like your everyday inkjet printer. The laser cutter comes with specific drivers which convert an image from a computer into a format that the laser cutter can read.

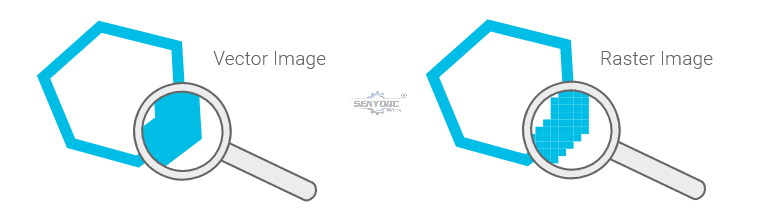

When working with laser cutters it is important to know the difference between vector images and raster images. Both image file types can be processed but raster images can only be used for engraving and not for cutting.

A vector image stores all the lines and colors as mathematical formulas. Raster images are pixel based. Which means that the image is made up of many small squares. Vector images can be scaled up without any loss in quality whereas raster images will start to “pixelate” at a certain enlargement.

Vector file types: SVG, EPS, PDF, DXF, DWG, CDR (CorelDRAW), AI (Adobe Illustrator)

Raster file types: JPG, PNG, GIF

You can use the software of your choice as long as you export your file in a suitable format. Below are some examples of graphic design software.

General settings

The first thing that should be considered is

the size of your material / the maximal size that the laser bed can

accommodate. This defines the maximum size of your design. In general,

it is a good idea to set the work area to this size.

The color

mode should be set to RGB. Different colors are usually used to specify

different processes. For example, red could be used for all the parts

that will be cut and black will be used for engraving.

Creating a file for laser cutting

As

explained before, during a cutting operation, the laser fires a

continuous beam at the material to slice through it. To know where to

cut the laser machine needs a vector path as the input file.

Only

vector graphics with the smallest possible line thickness (this depends

on the software you are using) will be cut by the laser. All other

graphics, like solid shapes or thicker lines, won’t be cut.

When cutting out text or other complex shapes you to consider that unconnected middle parts – like the inside of an “O” – will fall out. Depending on your desired design you may want to prevent this. For text you could, for instance, use a stencil font where all the inside parts of the letters are connected to the outside parts.

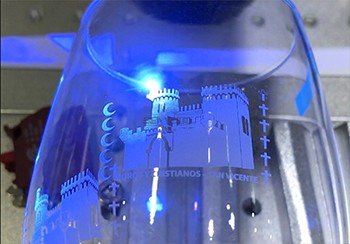

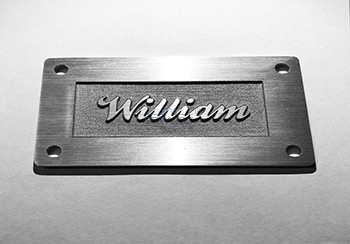

Creating a file for laser engraving

When engraving with a laser one can distinguish between vector engraving and raster engraving. Vector engraving is basically the same as cutting with the only difference that for the engraving the power is lower so that the laser just removes parts of the material and does not cut through.

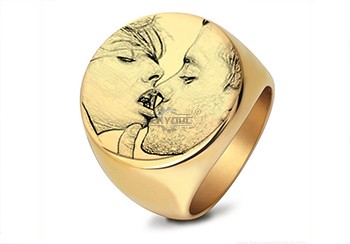

For raster engraving, the input file can either be a vector file or a raster image. During raster engraving, the image is engraved by the laser line by line, pixel by pixel. The process is similar to the way in which an inkjet printer applies ink, but instead of ink being applied, material is removed by the laser beam.

Engraving works for simple shapes as well as for complex images. Photos need to be turned into grayscale images to be engraved.

4. How to use a laser cutter?

Once you have your design

ready, it is time for the final step – the cutting on the laser. Laser

cutters are very powerful machines. You can create great things with

them but they are also potentially dangerous, so first a word of

warning.

Before using a laser cutter always first make sure you read

and understand all the safety instructions that come with it. In

addition be aware that that wavelength of a CO2 laser is in the

Infra-Red part of the light spectrum, so it is invisible to the human

eye ye. The red dot you see with many machines on the material surface

is only a positioning aid and not the laser beam that actually doing the

cutting.

Preparation

First of all, check that

your material fits inside the work area of the laser cutter and cut it

to size if necessary. Also, be prepared to make some test cuts or

engravings and bring some spare material with you.

You don’t necessarily need any extra tools when working with a laser cutter but in my experience, the following tool might come in handy:

Utility Knife: For cutting material that wasn’t cut all the way through by the laser cutter or to cut paper and cardboard to size.

Painter’s Tape/Masking Tape: Use it for masking the surface of your material to prevent burn stains and to tape down light materials.

Measurement Tape/Calipers: For measuring dimensions and making sure your final objects have the right size.

Settings

The four most important settings of a laser cutter are power, speed, frequency and for focus distance.

Power: Defines the output power of the laser. Typically can be set from 0 to 100% (maximum power). High power is used for cutting thick materials and lower power is used for engraving and cutting of thin materials such as paper.

Speed: Determines the movement speed of the laser head. For engraving and cutting of thin material, the speed is usually set (close) to the maximum.

Frequency (Hz, PPI): The frequency parameter specifies the number of laser pulses per second. Frequency depends completely on the material used. For example wood cuts best at around 500 to 1000 Hz and for acrylic 5000 to 20000Hz are recommended to achieve a smooth edge.

Focus: As previously explained, there is a focusing lens inside the laser head. The focus point (where the laser beam is thinnest) should be on the material surface or slightly below, for most applications. To ensure this the material needs to be a certain distance away from the lens. The exact distance depends on the type of focusing lens that is used.

Many laser machines have a motorized bed which can be moved up and down to set the focus distance. Alternatively the position of the material surface a has to be manually adjusted.

So now that you have a basic understanding of the available settings you might ask yourself how to find the right settings for your projects? A good starting point is the laser cutter manual. Often you will find suggested settings for many materials. If you are working on a shared laser in a makerspace there are usually lists with recommended settings available.

Time to Cut!

Finally, you should be prepared to make your first cuts. It can take a few tries to find the ideal settings for your material.

Always

change only one parameter in a test process. For example, start with

the power by testing different values in 5-10% increments. Once your

are happy with your results, don’t forget to write down your settings

for future reference.

• Previous: How does a laser cutter work?

• Next: How to Create Connected Text – Inkscape for Laser Cutting

- Fiber metal Laser Sensor And Its Application

- Laser Cutting Machine Inspection Process For Manufacture

- How Control Costs Use of UV Printers ?

- Why UV flat printing machine is popular in market ?

- How does UV ink jet printer save UV ink?

- Waterjet Machine delivery and Shipping

- Waterjet Machine finish manufacture 5axis

- Waterjet Machine delivery and Shipping

- How to Create Connected Text – Inkscape for Laser Cutting

- How to get started with laser cutting in 4 steps

- How does a laser cutter work?

- Wine butler

Jacob from United States

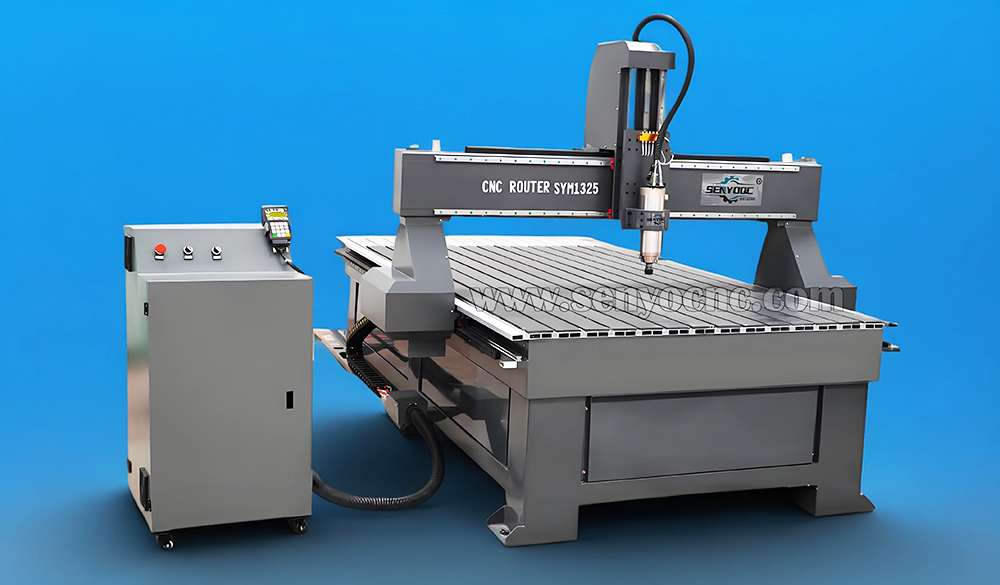

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

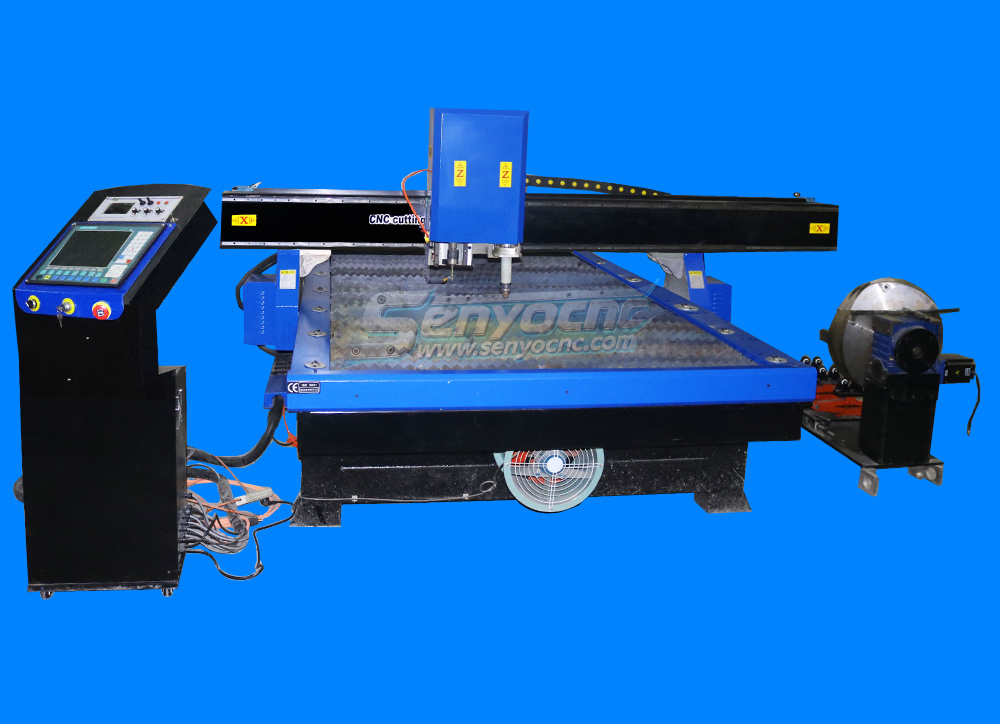

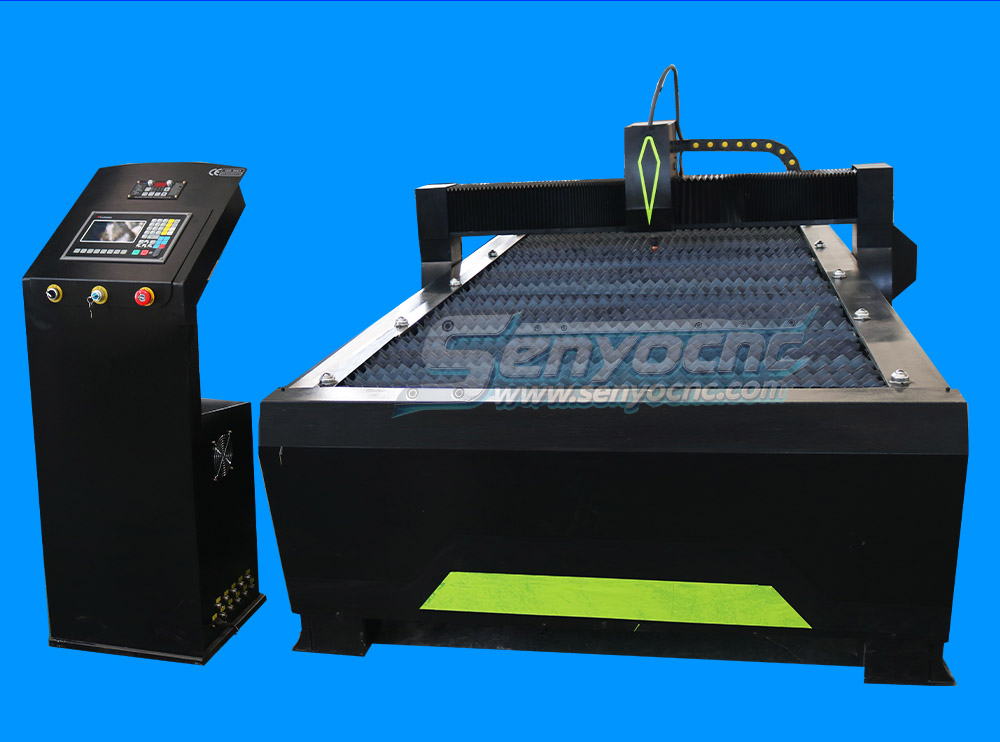

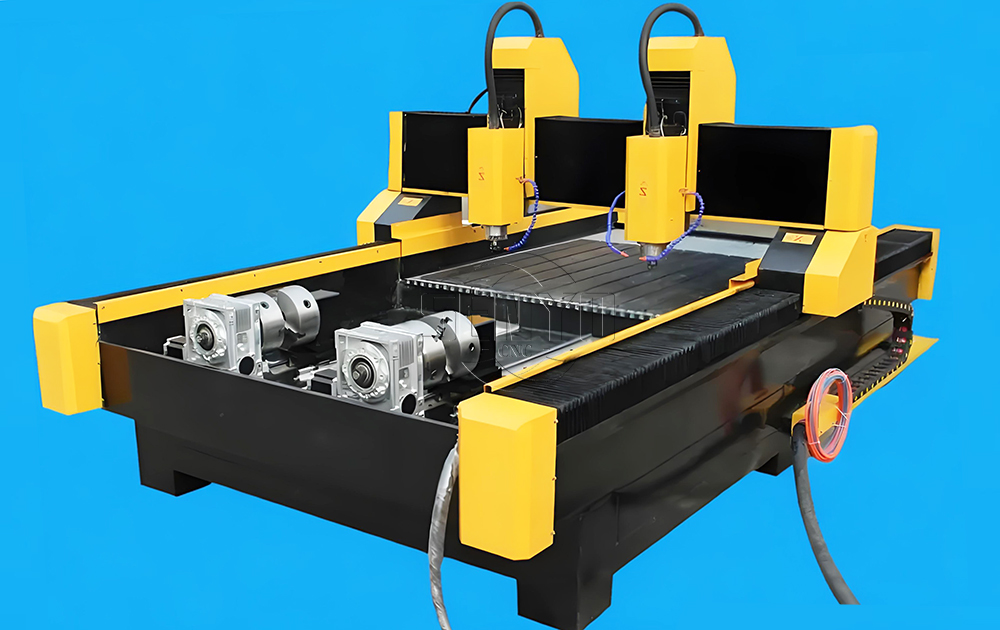

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

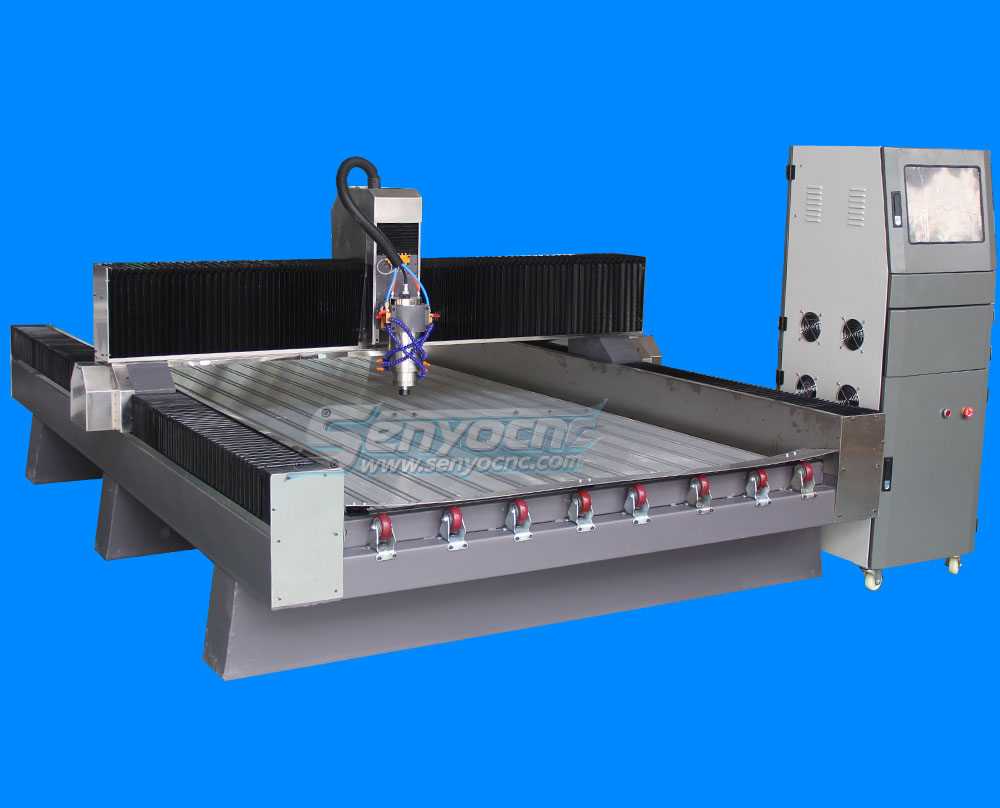

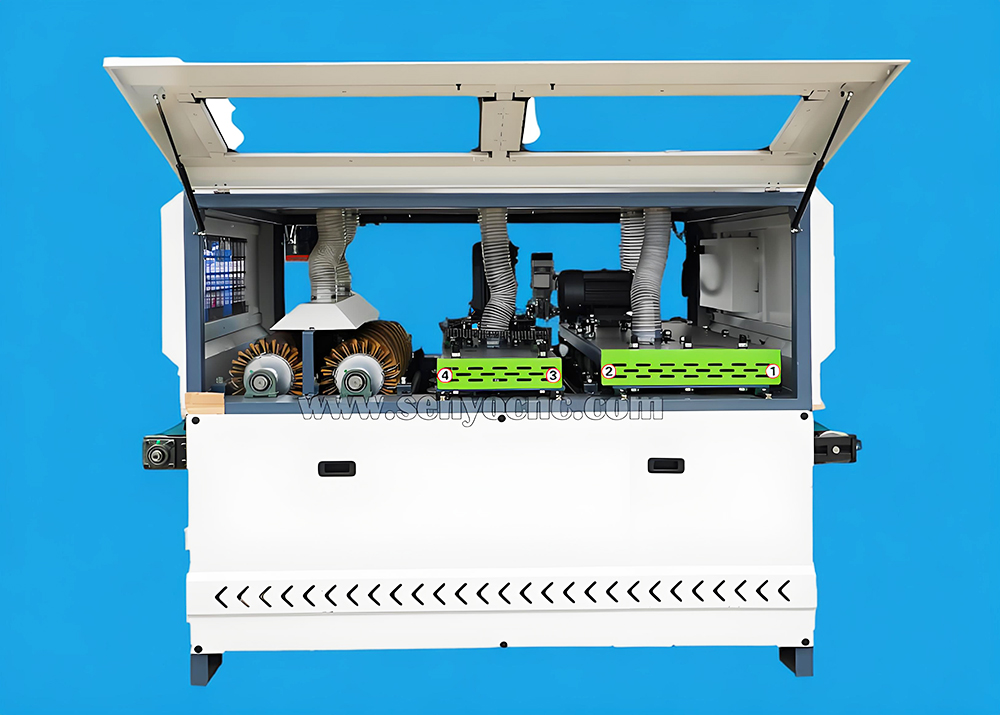

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

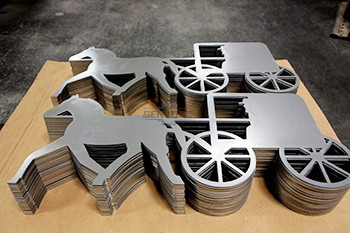

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

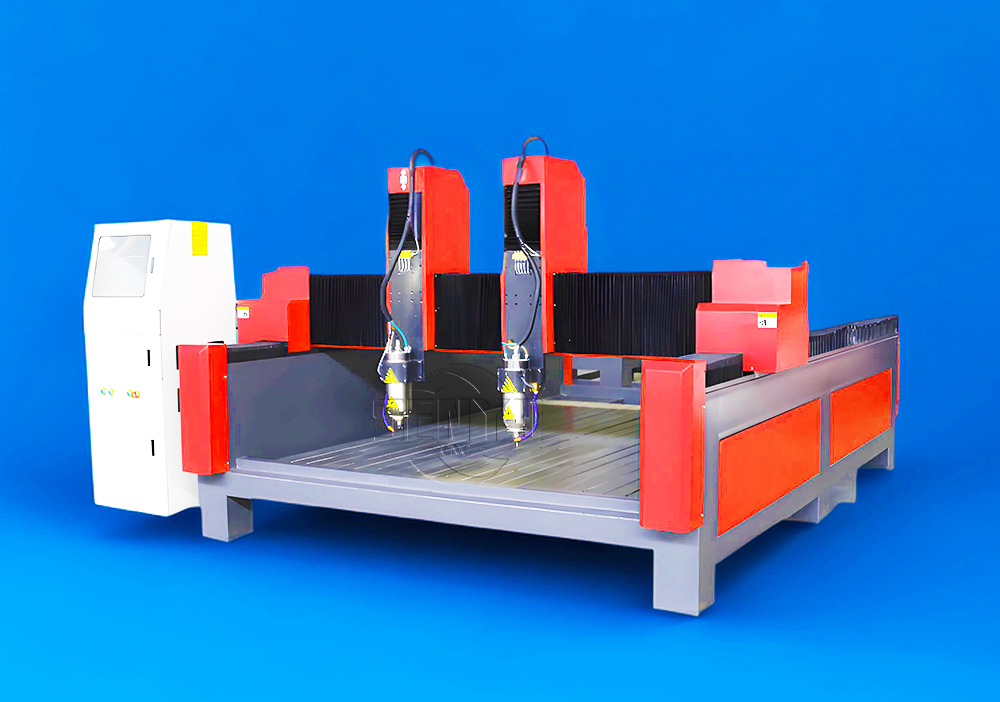

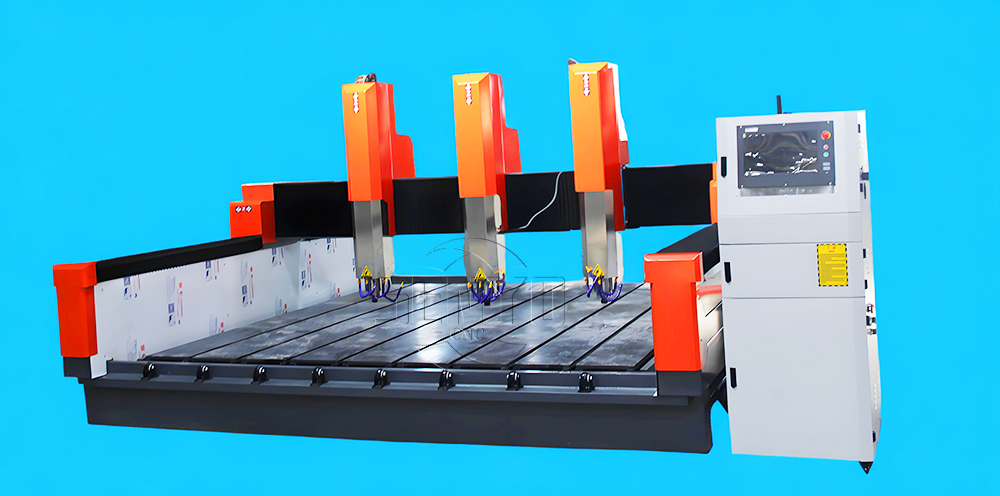

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

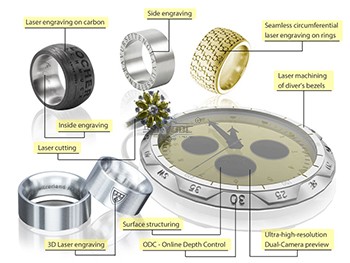

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344