Layout Design of a Furniture Prodtction Line Using Formal Method

From: 本站 Date: 31st August 2021 Author: shengangtong Views: 1487

Journal of Industrial and Systems Engineering

Vol. 1, No.1, pp81-96

Spring 2007

Layout Design of a Furniture Production Line Using Formal Methods

Pinto Wilsten J, Shayan E. *

Faculty of Engineering, Swinbume University of Technology, Hawthom, Victoria, Australia

ABSTRACT

This paper experiments application of different heuristic approaches to a real facility layout problem at a furniture

manufacturing company. All the models are compared using AHP, where a number of parameters of interest are

employed. The experiment shows that formal layout modelling approaches can be effectively used real problems

faced in industry, leading to significant improvements.

Keywords: Facilities layout design, Layout algorithms, Optimisation, Production lines.

1. INTRODUCTION

The fumniture industry is experiencing a very competitive era like many others, thus striving hard to find methods to

reduce manufacturing costs, improve quality etc. As part of a productivity improvement program in a manufacturing

company herein called (The Company = TC) we conducted a project to optimize the layout design of the production

line at the shop floor of this company aiming at overcoming the current problems attributed to the inefficient layout. It

was decided to apply a number of layout modelling techniques to generate a near optimal layout based on formal

methods that are rarely used in practice. The modelling techniques used are Graph Theory, Bloc Plan, CRAFT,

Optimum Sequence and Genetic Algorithm. These layouts were then evaluated and compared using three criteria

namely Total Area, Flow * Dist and the Adjacency Percentage. Total Area refers to the area occupied by the

production line for each model developed. Flow * Dist calculates the sum of products of the flow and the distance

between every two facilities. Adjacency Percentage calculates the percentage of the facilities that meet the

requirement of being adjacent.

Selection of the best layout was also done formally usingmulti-criteriadecision making approach AHP (Satty, 1980)

using Expert Choice software. The best layout was compared with the existing layout to demonstrate improvements

gained by formal approaches to layout design.

The definition of a plant layout problem is to find the best arrangement of physical facilities to provide an efficient

operation (Hassan and Hogg, 1991). The layout affects the cost of material handling, lead time and throughput. It

hence affects the overall productivity and efficiency of the plant. According to Tompkins and White (1984) the design

of facilities has been around throughout recorded history and indeed town facilities that were designed and built are

described in the ancient

* Corresponding Author

history of Greece and the Roman Empire. Among the first who studied this problem are Amour and Buffa et al.

(1964). Little seems to have been published in the 1950's. Francis and White (1974) were the first who collected

and updated the early research on this area. Later research has been updated by two studies the first by Domschke

and Drexl (1985) and the other by Francis et al. (1992). Hassan and Hogg (1991) reported an extensive study on

the type of data required in the machine layout problem. The machine layout data is considered in a hierarchy;

depending on how detailed the layout is designed. When the layout required is only to find the relative arrangement

of machines, data representing machine number and their flow relationships are sufficient. However, if a detailed

layout is needed, more data is required. In finding data some difculties may arise especially in new manufacturing

facilities where the data is not yet available. Whenthe layout is developed for modern and automated facilities, the

required data cannot be obtained from historical data or from similar facilities since they may not exist.

Mathematical modelling has been suggested as a way to get an optimal solution for the facility layout problem.

Since the first mathematical model developed by Koopmans and Beckmann (1957) as a quadratic assignment

problem, interest in the area has attracted considerable growth. This opened up a new and interesting field for the

researcher. In searching for a solution to the facility layout problem, researchers launched themselves into

developing mathematical models. Houshyar and White (1993) looked at layout problem as

aninteger-programmingmodel while Rosenblatt (1986) formulated the layout problem as a dynamic programming

model. Palekar et al. (1992) deal with uncertainty and Shang (1993) uses amulti-criteriaapproach. On the other

hand, Leung (1992) presented a graph theory formulation.

Green andAl-Hakim(1985) used a GA to find the part family as well as the layout between cells. In his formulation,

he limited the arrangement of cell as either linear single row or linear double row. The developed algorithm is more

towards the cells system layout, or the layout of production floor, rather than the cell layout, or the machine layout.

The actual layout of machines within cells was not considered. Banerjee and Zhou (1995) formulated the facilitis

design optimization problem for asingle-looplayout using genetic algorithms. The developed algorithm is for the cell

systems layout and hence does not consider the layout of machines within cell. Fu and Kaku (1997) presented a

plant layout problem formulation for a job shop manufacturing system where the objective is to minimize the

average Work in Process. They modeled the plant as an open queuing network under a set of assumptions. The

problem reduces to a Queuing Assignment Problem (QAP). Simulation was used to minimize the average Material

Handling costs and minimizing the Average Work in Process.

2. MODELING APPROACHES

Models are categorised depending on their nature, assumptions and objectives. The first generic Systematic L ayout

Planning approach, developed by Muthor (1955), is still a useful scheme specially if supported by other approaches

and assisted by computer. Construction approaches, Hassan and Hogg (1991) for example, build a layout from

scratch while Improvement Methods, Bozer, Meller and Erlebacher (1994) for example, attempt to modify an

existing layout for better results. Optimising methods and also heuristics for layout by is well documented by Heragu

(2007).De-Alvarengaand Gomes (2000) discuss ameta-heuristicapproach as a way to overcome the NP- hard

nature of optimal models.

The various modelling techniques used in this work are Graph Theory, CRAFT, Optimum Sequence, BL _OCPL AN

and Genetic Algorithm. Explained below are parameters that are required by each algorithm in order to model the

same.

Graph Theory

Graph theory (Foulds and Robinson, 1976; Giffin et al., 1984; Kim and Kim, 1985; and Leung,

1992)applies an edge–weight maximal planar graph in which the vertices (V) represents the

facilities and the edges (E) represent adjacencies and Kn denotes the complete graph of n Vertices.

Given a weighted graph G, the facility layout problem is to find a maximum weighted spanning

sub-graph G’ of G that is planar.

This paper uses 2 different kinds of approaches to model the case study. The first approach is the

Delta-hedron method by Foulds and Robinson (1976). The method involves simple insertion with

an initial K4, and vertices are then inserted one by one according to a benefit criterion. The second

approach used is the wheel expansion algorithm (Green and Al-Hakim, 1985). Here the initial K4 is

obtained by selecting an edge having the highest weight and then applying two successive vertex

insertion according to the benefit criteria. The algorithm then proceeds with an insertion process,

called the wheel expansion procedure. A wheel on n vertices is defined as a cycle on (n-1) vertices

(termed the rim), such that each vertex is adjacent to one additional vertex (termed the hub). Let W

be a wheel having the hub x. Select two vertices k and l, which are the rims of this cycle. A vertex y

from the set of unused vertices is then inserted to this wheel in the current partial sub-graph such

that y is a hub of the new wheel W′ containing k, l and x as its rims, and all rims in W are now

adjacent to vertex x or vertex y. By inserting each unused vertex successively in the above fashion,

the final maximal planar sub graph is obtained.

Using CRAFT

CRAFT (Computerized Relative Allocation of Facilities Technique) uses a pair wise exchange to

develop a layout (Buffa et al., 1964; Hicks and Lowan, 1976). CRAFT does not examine all

possible pair wise exchange before generating an improved layout. The input data includes

dimensions of the building and facilities, flow of material or frequency of trips between facility

pairs and cost per unit load per unit distance. The product of the flow (f) and distance (d) provides

the cost of moving materials between 2 facilities. The cost reduction is then calculated based on the

pre and post exchange material handling cost contribution.

Optimum Sequence

The method of solution starts with an arbitrary sequential layout and tries to improve it by switching

two departments in the sequence (Heragu, 1997). At each step, the method computes the

flow*distance changes for all possible switches of two departments and chooses the most effective

pair. The two departments are switched and the method repeats. The process stops when no switch

results in a reduced cost. The input required to generate a layout using Optimum Sequence are

mainly dimensions of the building and facilities, the flow of material or frequency of trips between

facility pairs and cost per unit load per unit distance.

Using BLOCPLAN

BLOCPLAN is an interactive program used to develop and improve both single and multi storey

layout (Green and Al-Hakim, 1985). It is a simple program which generates good initial layouts due

to its flexibility based on several imbedded options. It uses both quantitative and qualitative data to 84

Pinto and Shayan generate several block layouts and their measure of fitness.

The user can choose the relative solutions based on circumstances.

Genetic Algorithm

There are numerous ways of formulating facilities Layout problems through genetic

algorithms(GA). Banerjee, Zhou, and Montreuil(1997) applied GA to cell layout.. Slicing

tree structure was first suggested by Otten (1982) as a way to represent a class of layouts. The

approach was later used by many authors including Tam and Chan (1995) who used it to solve

the unequal area layout problem with geometric constraints. The GA algorithm used in this

work was developed by Shayan and Chittilappilli (2004) based on slicing tree structures (STC). It

codes a tree structured candidate layout into a special structure of 2 dimensional chromosomes

which shows the relative location of each facility in a slicing tree. Special schemes are available to

manipulate the chromosome in GA operations (Tam and Li, 1991). A new “cloning” operation was

also introduced in Shayan and Al-Hakim (1999). The chosen solution through GA is then

converted to a slicing layout. It starts with one initial block that contains all the facilities. As the

layout constructing algorithm progresses, new partitions are made and facilities are assigned

between newly generated blocks, until there is only one facility in each block. Meanwhile the

coordinates of each facility is also calculated. Rectilinear distance between centroids of facilities is

used to evaluate the fitness of the respective chromosome. When the GA terminates, a drawing

procedure takes over to print the layout using the stored values of the coordinates. The objective

function has a penalty term to avoid narrow slices.

3. EXPERIMENTATION VIA A CASE STUDY

To test the performance of the methods described before, they were all applied to a real case

scenario in furniture manufacturing. The Company manufactures 9 different styles of Chairs, 2-

Seaters and 3-Seaters respectively. Production of all the styles follows the same set of operations

but involve different raw materials. 5 parts namely Seat cushions, Back cushions, Arms Seats and

Backs are produced internally in batches of varied sizes, in scattered areas (departments).

Movement of parts generates problems such as work in progress, missing parts, shortages,

congestion and wrong placement.

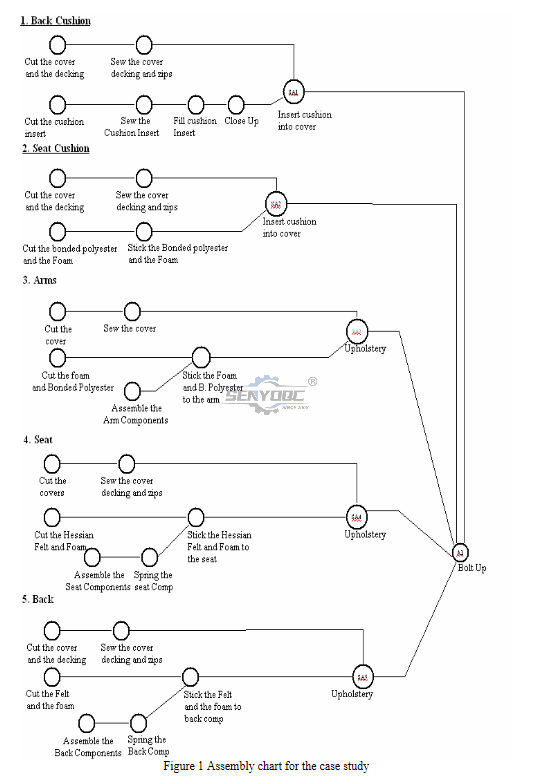

Each product goes through 11 operations which begin at Facility 1 – Cutting Area and end at

Facility 11- Bolt up Area. Each of the final assembly can be broken down into subassemblies

named the same. These subassemblies meet up at the Bolt -Up Facility for final assembly. Each of

the subassemblies begin their operations independently and all go through a fixed set of operations

which is shown in the form of an assembly chart in Fig 1. The facilities of the current layout are not

placed according to the sequence of operations.

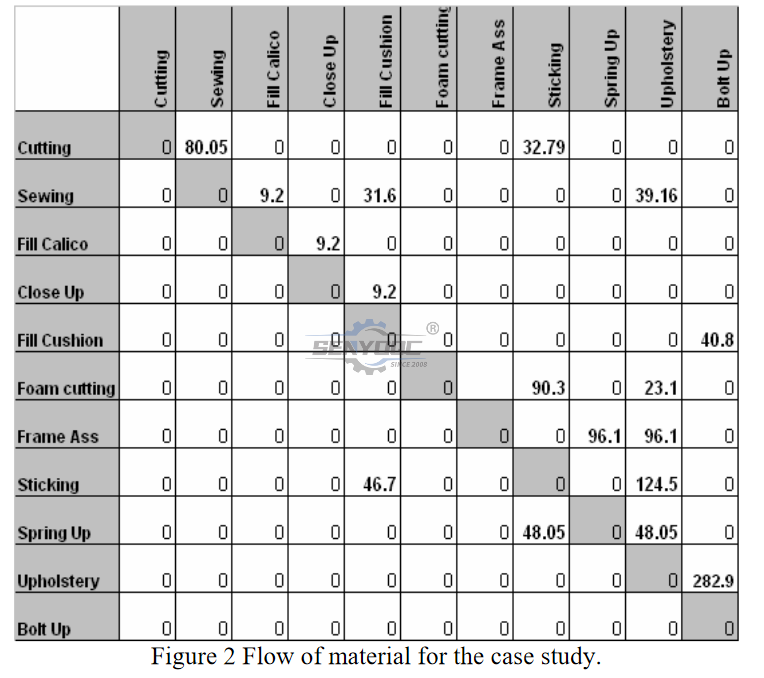

Due to this there is no sequential flow of materials, giving rise to work in progress. The interaction

between facilities can be determined using subjective as well as objective measures. The main input

required for flow charts is the demand, the quantity of materials produced and the amount of

material that flows between each machine. The flow of material is calculated based on amount of

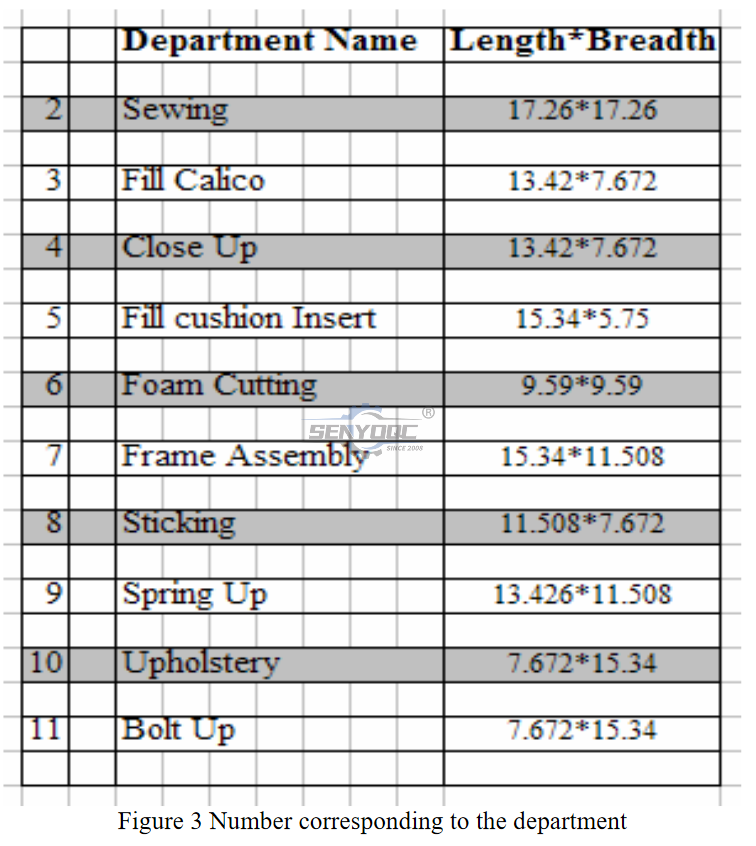

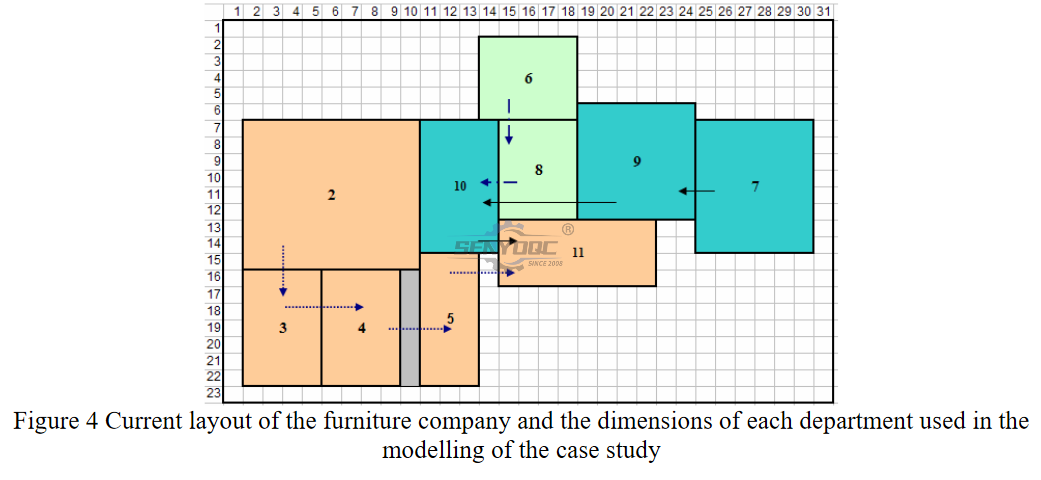

flow of material traveling per 10 months * Unit of measure which is shown in Figure 2. Figure 3

shows the area of each of the department used in the case study. Figure 4 shows the current layout

of the Case Study.

4. APPLICATION OF THE MODELING APPROACHES

Here the various modelling approaches discussed in section 2 are applied to the case study to

generate alternative layouts for comparison.

4.1 Using Graph Theory

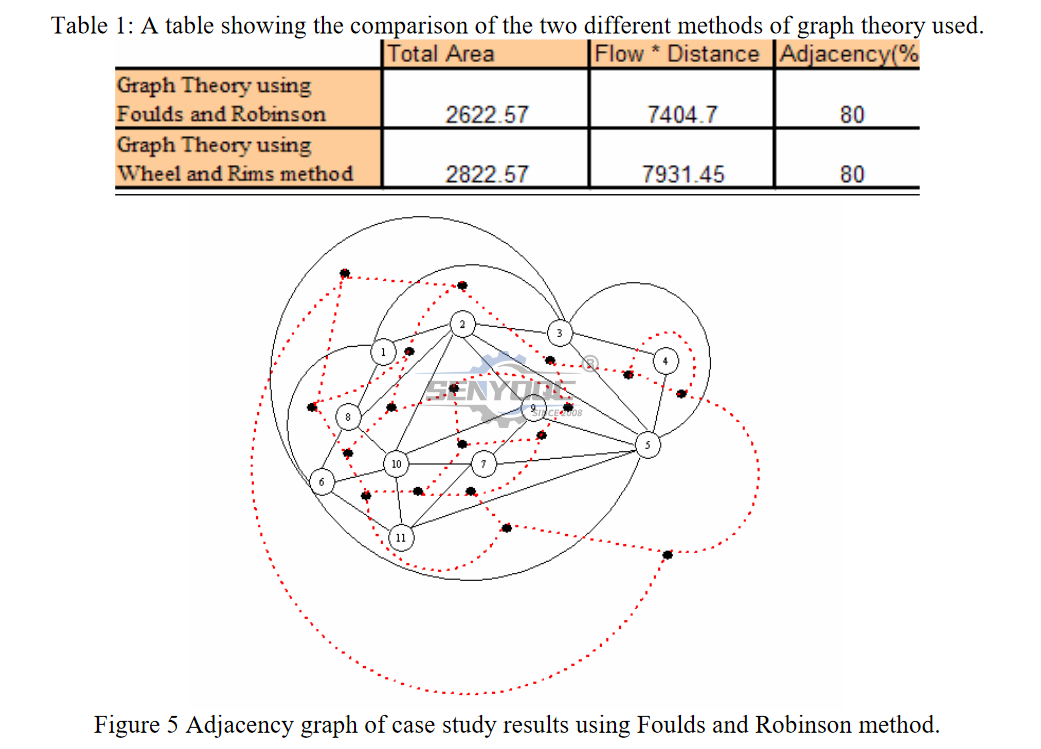

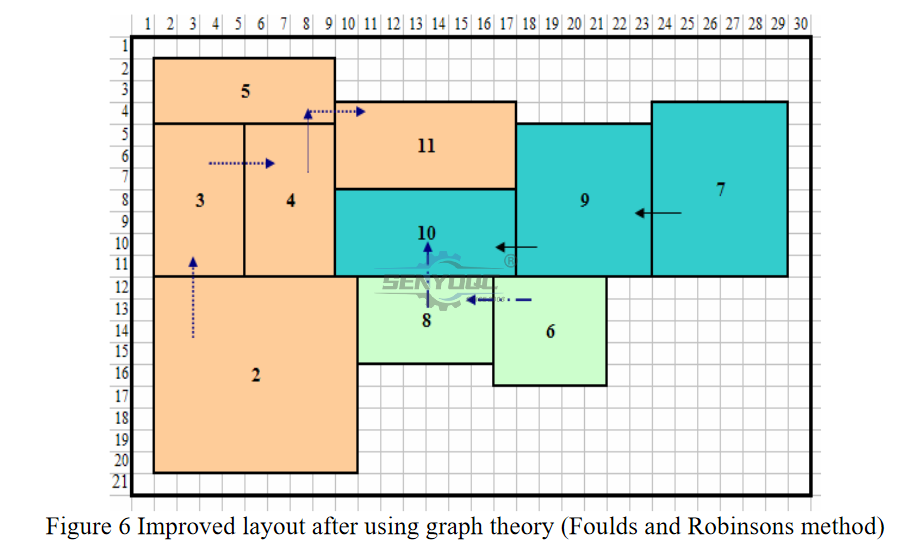

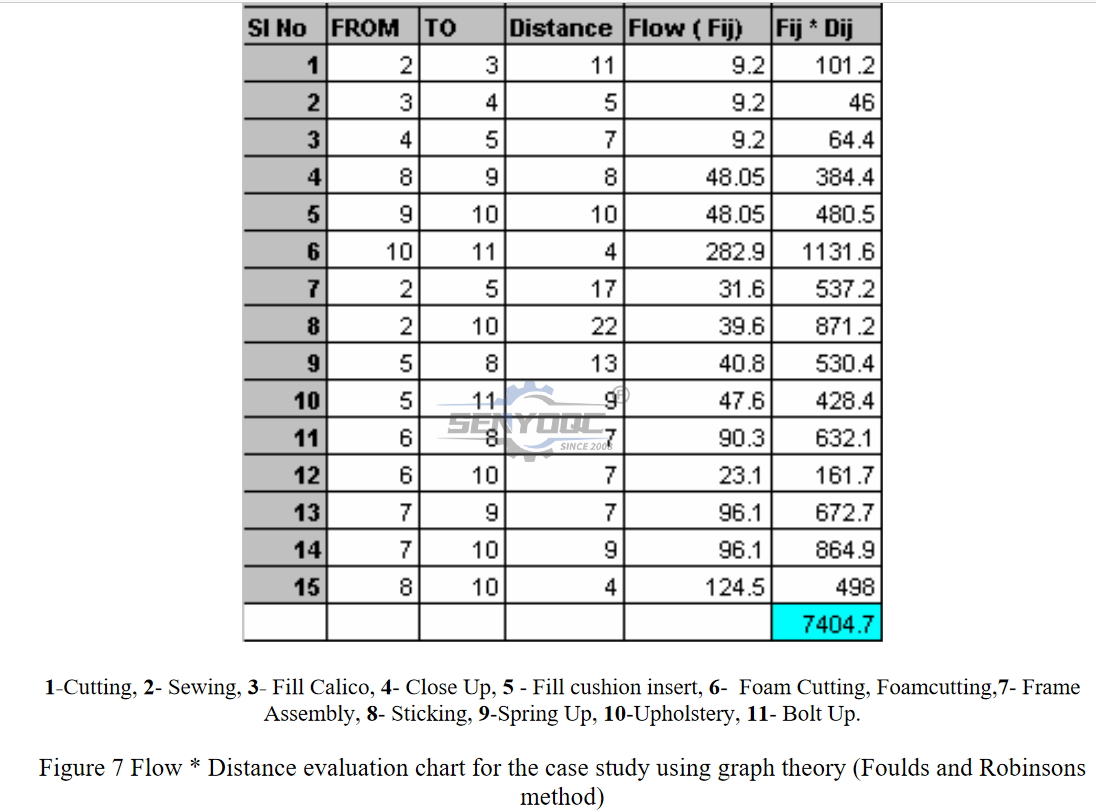

Table 1 shows the comparison of the results using two different approaches of Graph Theory

namely the Foulds and Robinsons method and the Wheels and Rims method. Table 1 it clearly

shows that the Foulds and the Robinsons method is the better of the two results. The results of the

Foulds and Robinsons method are explained in detail in Figures 5-7.

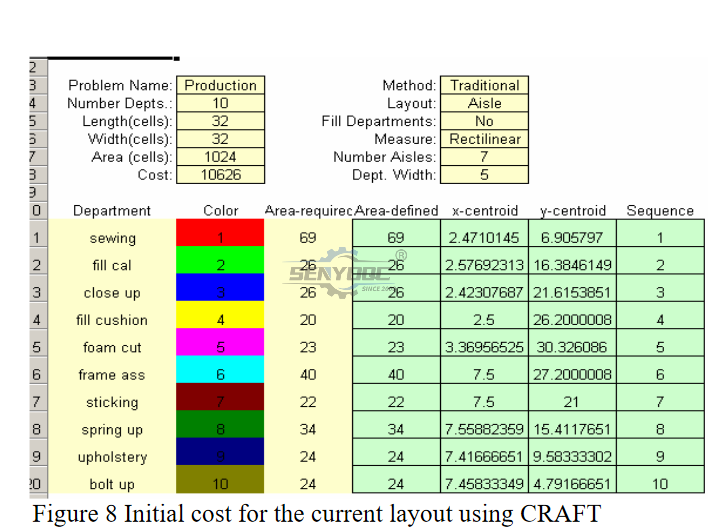

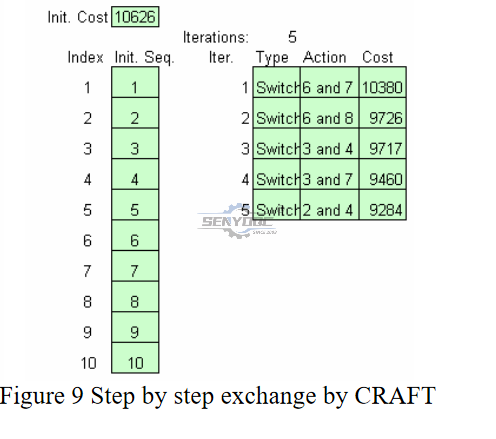

4.2 Using CRAFT

The input data for CRAFT is entered and the initial cost for the current layout is first calculated.

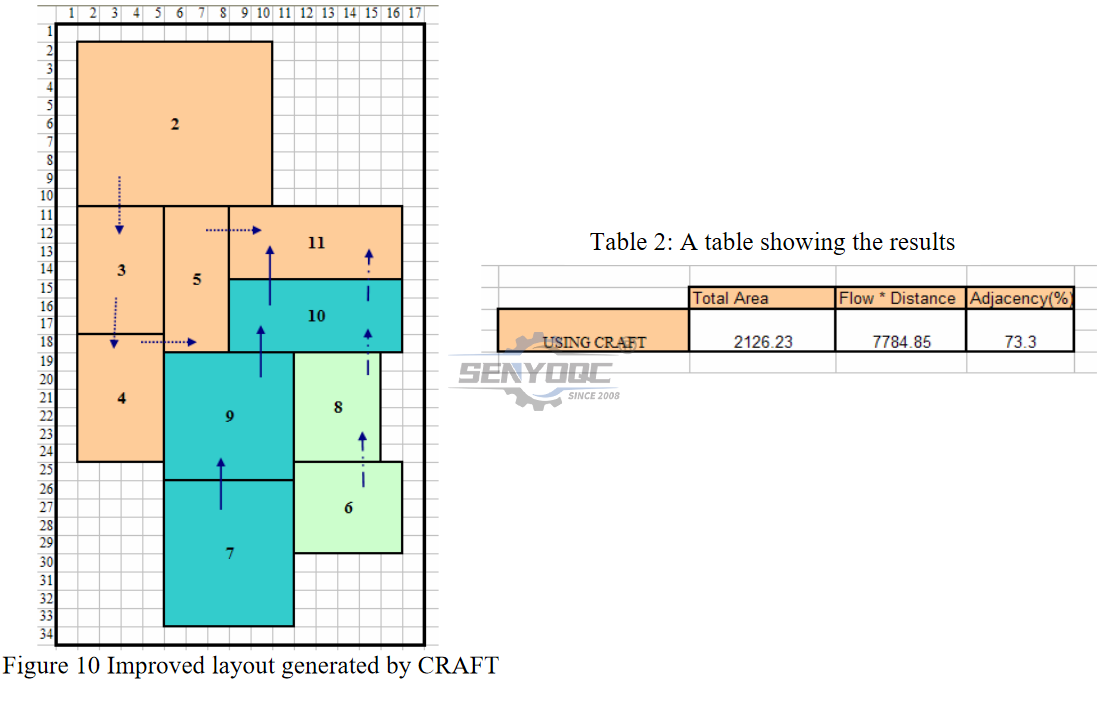

This cost can be reduced using a pair wise comparison as shown in Figures 8,9.

The results obtained by CRAFT are shown in Table 2. Based on the above calculations a new and

improved layout can be drawn which is shown in Figure 10

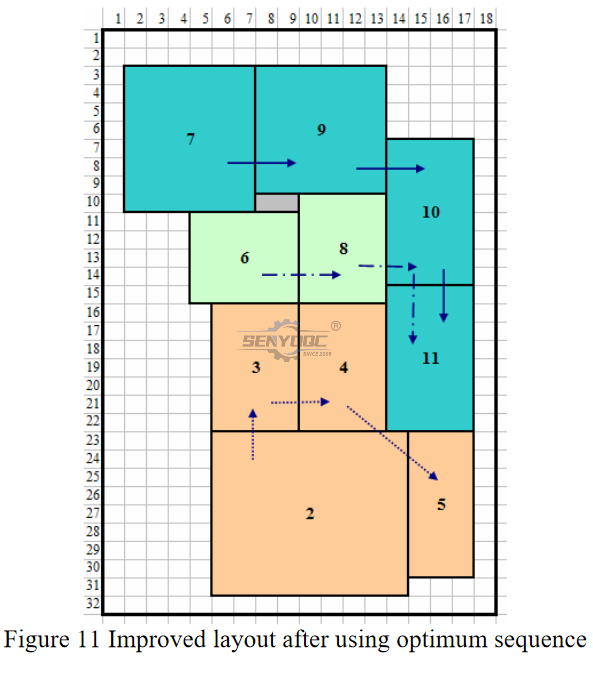

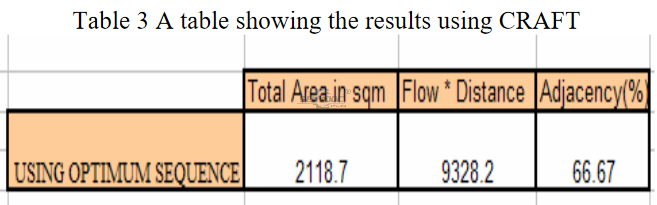

4.3 Optimum Sequence Algorithm

The input data is the same as for CRAFT except that it follows a different set of pair wise

comparison. Table 3 shows the results drawn from the improved layout. Figure 11 shows the

improved layout using Optimum Sequence.

4.4 Using BLOCPLAN

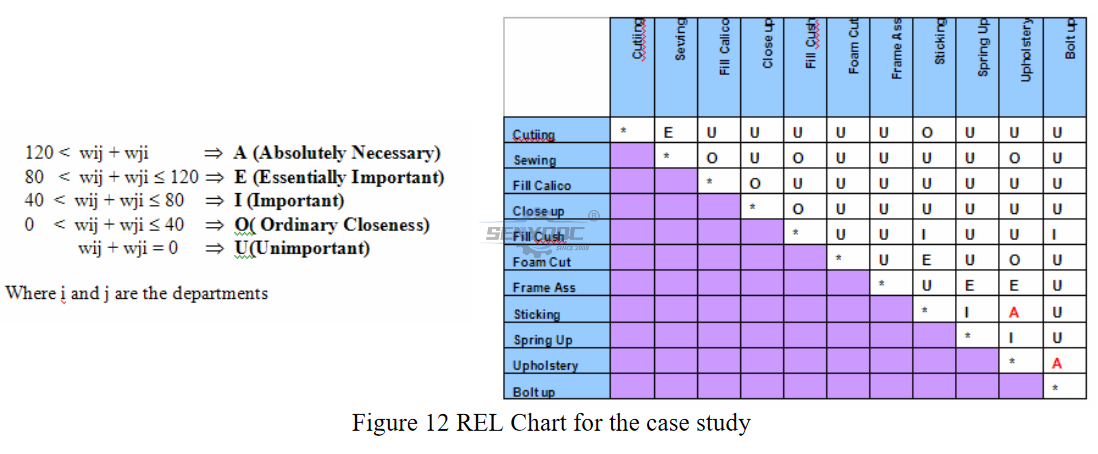

The Flow matrix chart was converted to a REL chart as shown in Figure 12 with the following

parameters:

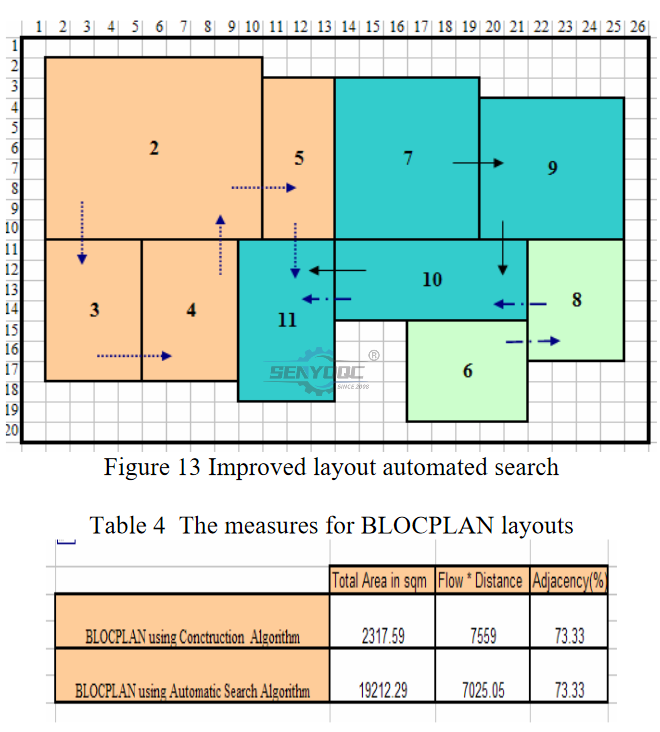

Table 4 shows the results using different kinds of approach. As seen the BLOCPLAN using an

automated search showed better results than using the Construction Algorithm.

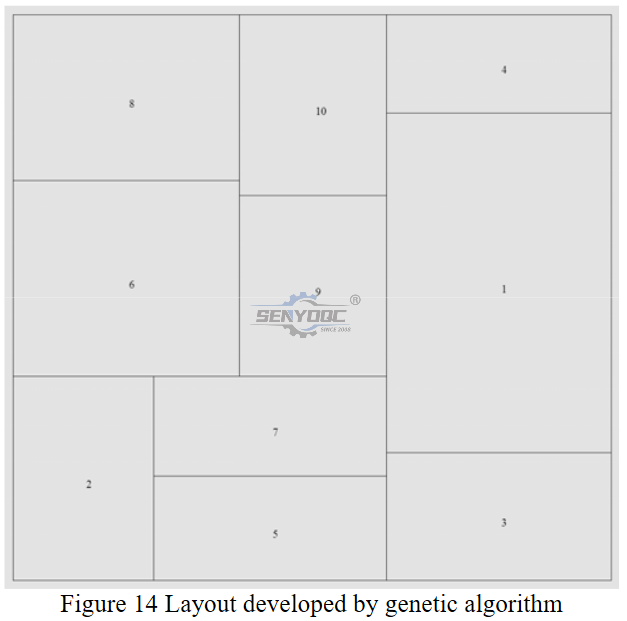

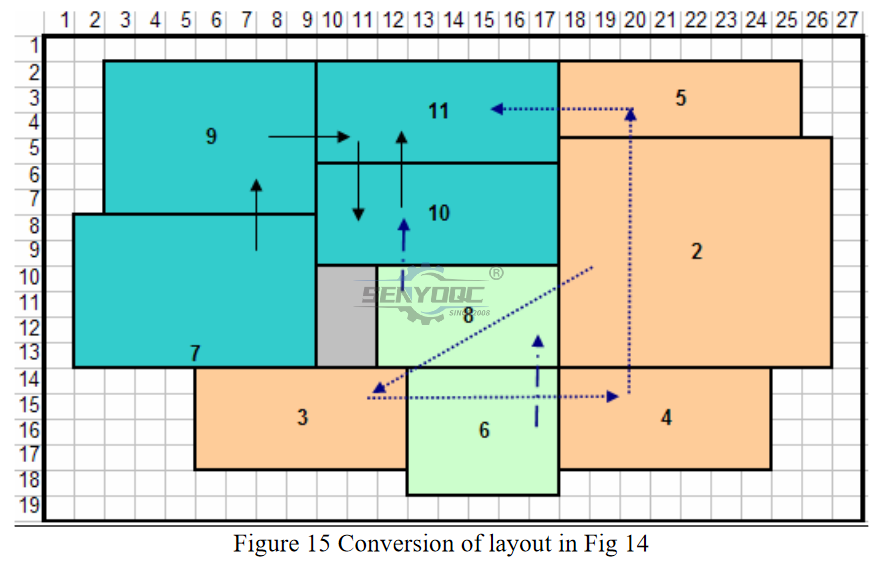

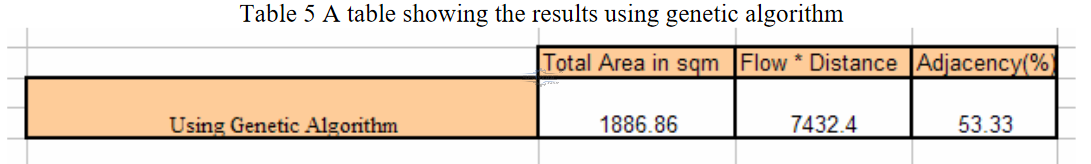

4.5 Using Genetic Algorithm

The best solution found by the algorithm is shown in Figure 14. This is then converted to the layout

in Figure 15 for common comparisons with other models.

Table 5 shows the results using Genetic Algorithm.

5. COMPARISONS OF EXPERIMENTATION RESULTS BY AHP

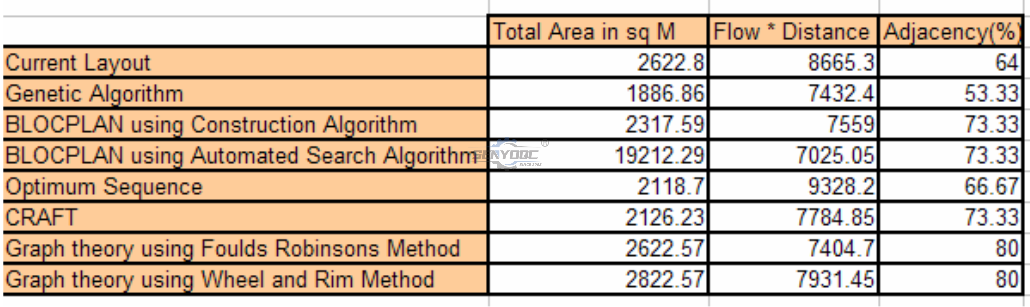

Table 6 summarizes the results obtained from all the modelling techniques versus the Current

Layout for comparison. Section of the best layout will be done based on three factors namely Total

Area (Minimze), Flow * Distance (Maximize) and the Adjacency percentage (Maximize). The main

objective is to reduce the WIP and organise a systematic flow of materials. As a result the flow *

distance matrix is the most important parameter.

Table 6 Summary of results using all modelling techniques versus the results of the current layout

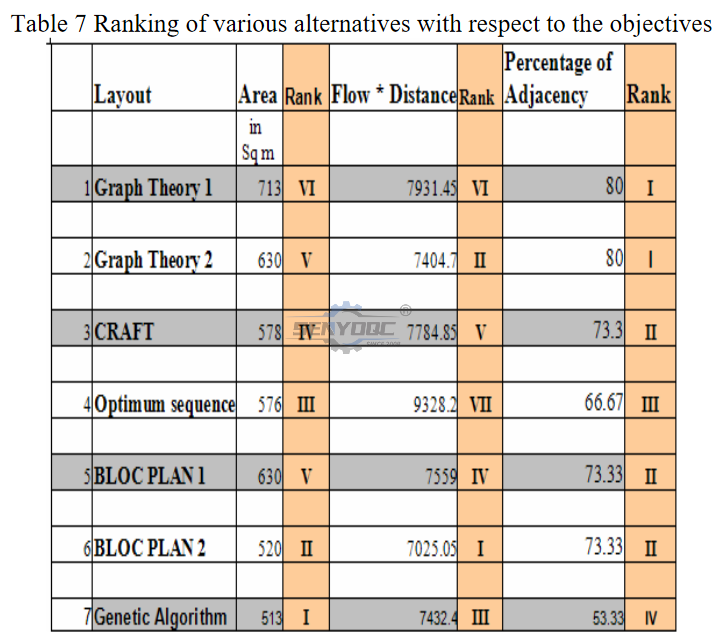

Table 7 shows the mix ranking of the alternative layouts based on various factors. For example

Layout 1 has a poor rank in Area and F*D while is the best in Adjacency. The combination makes it

difficult to choose one over the others. We urge to use a formal technique, AHP, implemented by

Expert Choice software

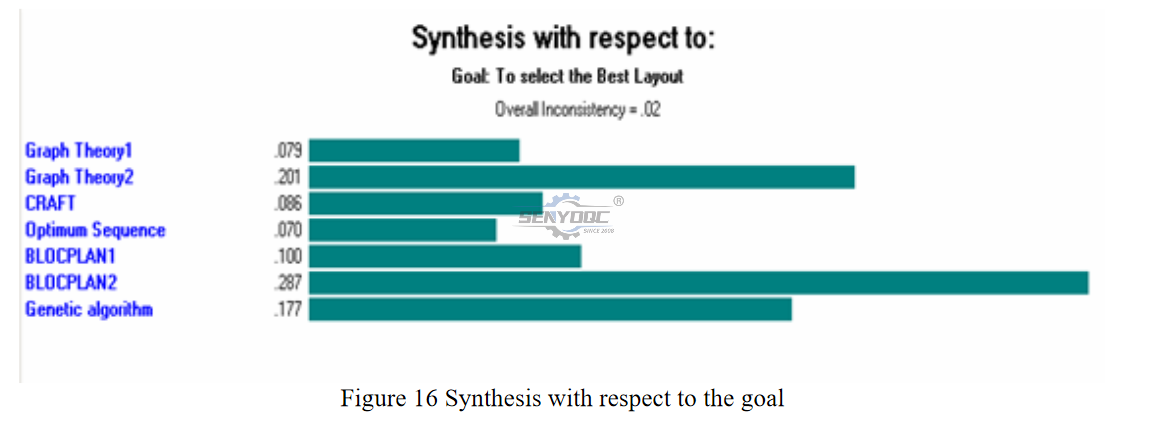

AHPcompares the relative importance of each pair of children with respect to the parent. Once the

pair comparisons is completed, the approach synthesis the results using some mathematical models

to determine an overall ranking. Figure 16 shows the ranking of the results achieved from all

algorithms with respect the goal of best choice solution.

The best solution is achieved by BLOCPLAN ( Automated Search) followed by Graph Theory

using Foulds and Robinsons Method, then Genetic Algorithm. The other solutions are far worse.

Note that due to the inherent subjectivities ranking is not an absolute indication of better choice,

rather it is a recommendation that the user can entertain to suit the needs. 94

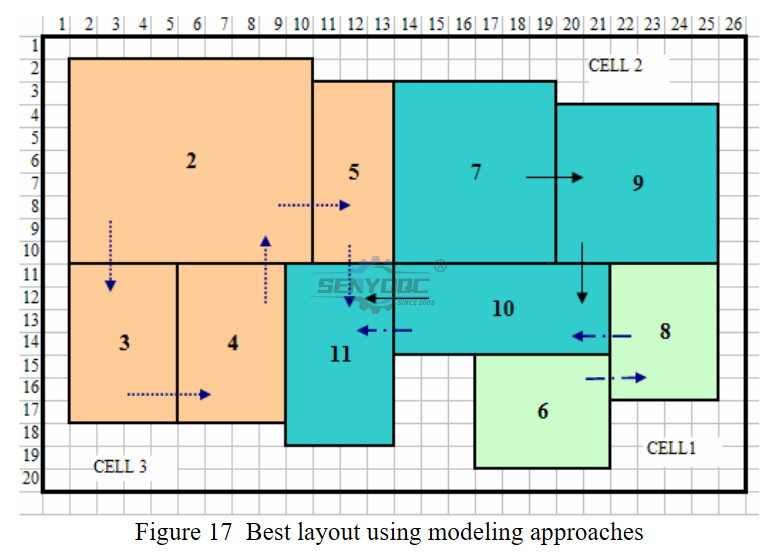

We propose the layout generated using BLOCPLAN using Automated Search to be the chosen

solution. When this was decided a sensitivity analysis was conducted to ensure that the choice is

robust. If time allows this should be done for other close alternatives before the choice is made.

6. CONCLUSIONS

The goal in this paper was to use various modelling techniques to select the best layout for a

furniture company. The best layout was generated by BLOCPLAN using Automated Search as figure 17.

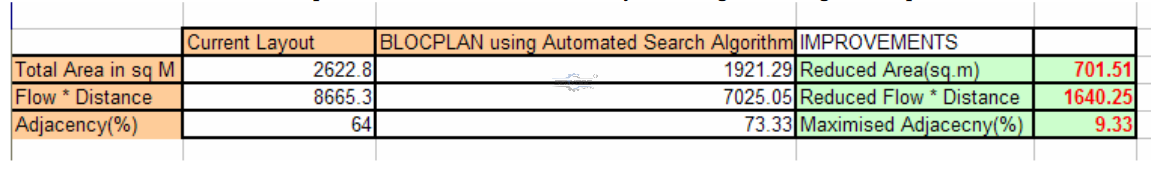

Table 9 shows the improvements of the proposed solution over the current layout. Note that the

layout shows the blocks and their relative locations. Practical limitations need to be applied to suit

all the needs. Then further details of each block can be planned, if necessary in the same manner.

Table 9: Improvements over the current layout using modeling techniques

The result was quite satisfactory to the company, which did not have any knowledge of the

scientific approaches.

REFERENCES

[1] Banerjee P., Zhou Y. (1995), Facilities layout design optimization with single loop material flow

path configuration; Int. Journal of Production Research 33(1); 183-204.

[2] Banerjee P., Zhou Y., Montreuil B. (1997),Genetically assisted optimization of cell layout and

material flow path skeleton; IIE Trans 29(4); 277-292. Layout Design of a Furniture... 95

[3] Bozer Y.A, Meller R.D., Erlebacher S.J. (1994), An improvement type layout algorithm;

International Journal of Production Research 1; 1675-1692.

[4] Buffa E.S., Armour G.C., Vollman T.E. (1964), Allocating facilities with CRAFT; Harvard Business

Review 42; 136-159.

[5] De-Alvarenga A.G., Gomes N.J., Mestria M. (2000), Metaheuristic methods for a class of the facility

layout problems; Journal of Intelligent Manufacturing 11; 421-430.

[6] Domschke W., Drexl A. (1985), Location and layout planning, An international bibliography;

Springer Verlag, Berlin.

[7] Foulds L.R., Robinson D.F. (1976), A strategy for solving the plant layout problem; Operational

Research Quarterly 27; 845-855.

[8] Francis R.L., McGinnis Jr. L.F., White J.A. (1992), 2nd Ed, Facility layout and location, An

analytical approach; Prentice Hall; Englewood Cliffs, NJ.

[9] Fu M.C., Kaku B.K. (1997), Minimizing work in progress and material handling in the facilities

layout problem; IIE Trans 29; 29-36.

[10] Giffin J.W., Foulds L.R. Cameron D.C. (1984), Drawing a block plan from a REL chart with graph

theory and microcomputer; Computers & Industrial Engineering 10; 109-116.

[11] Green R.H., Al-Hakim L. (1985), A heuristic for facilities layout planning; OMEGA, International

Journal of Management Science 13; 469-474.

[12] Hassan M.M.D., Hogg G.L. (1991), On constructing a block layout by graph theory;

International Journal of Production Research 29; 1263-1278.

[13] Heragu S.S. (2007), 2nd Ed, Facilities Design; iUniverse Inc., NY.

[14] Hicks P.E., Lowan T.E. (1976), CRAFT-M for layout re-arrangement; Industrial Engineering 8(5);

30-35.

[15] Houshyar A., White B. (1993), Exact optimal solution for facility layout – deciding which pairs of

locations should be adjacent; Computers and Industrial Engineering 24(2); 287-290.

[16] Kim J.Y., Kim Y.D. (1985), Graphic theoretic for unequal sized facility layout problems; OMEGA,

International Journal of Management Science 23; 391-401.

[17] Koopmans T.C., Beckmann M. (1957), Assignment problems and the location of Economic

Activities; Econometrica 25(1), 53-76.

[18] Leung J.A. (1992), A new graph theoretic heuristic for facility layout, Management Science 38; 554-

605.

[19] Meller R.D., Narayanan V., Vance P.H. (1998), Optimal facility layout design; Operation Research

Letters 23;117-127.

[20] Muther R. (1955), Practical plant layout; McGraw-Hill; New York, NY.

[21] Otten R.H.J.M. (1982), Automatic floor plan design; Proceedings of the 19th ACM-IEEE

DesignAutomation Conference; 261-267. 96

[22] Palekar V.S., Batta R., Bosch R.M., Elhence S. (1992), Modeling uncertainties in plant layout

problems; European Journal of Operations Research 63(2); 347-359.

[23] Rosenblatt M.J. (1986), The dynamics of plant layout; Management Science 32(1); 76-86.

[24] Satty T.L. (1980), Analytical hierarchic process; McGraw Hill; New York.

[25] Shang J.S. (1993), Multicriteria facility layout problem -An integrated approach; European Journal

of Operational Research; 66(3); 291-304 .

[26] Shayan E., Al-Hakim L., 1999. "Cloning in layout design problem: A genetic algorithm approach."

Proceedings of the 15th International Conference on Production Research; Hillery, M., Lewis, H.

Eds.), University of Limerick, Ireland; 787-792.

[27] Shayan E., Chittilappilly A.(2004) , Genetic algorithm for facilities layout problems based on slicing

tree structure; Int. J Production Research; 42(19); 4055–4067.

[28] Tam K.Y., Chan S.K. (1998), Solving facility layout problems with geometric constraints using

parallel genetic algorithms: experimentation and findings; International Journal of Production

Research 36(12); 3411-3423.

[29] Tam K.Y., Li S.L. (1991), A hierarchal approach to facility layout problem; International Journal

Production Research, 29; 165-184.

[30] Tompkins J.A., White J.A. (1984), Facilities planning; John Wiley & Sons, NY.

![]() Layout Design of a Furniture Prodtction Line Using Formal Method.pdf

Layout Design of a Furniture Prodtction Line Using Formal Method.pdf

• Previous: A practical guide for beginners to set up, debug and use the plasma cutting machine

• Next: How choose a suitable Panel furniture production line ?

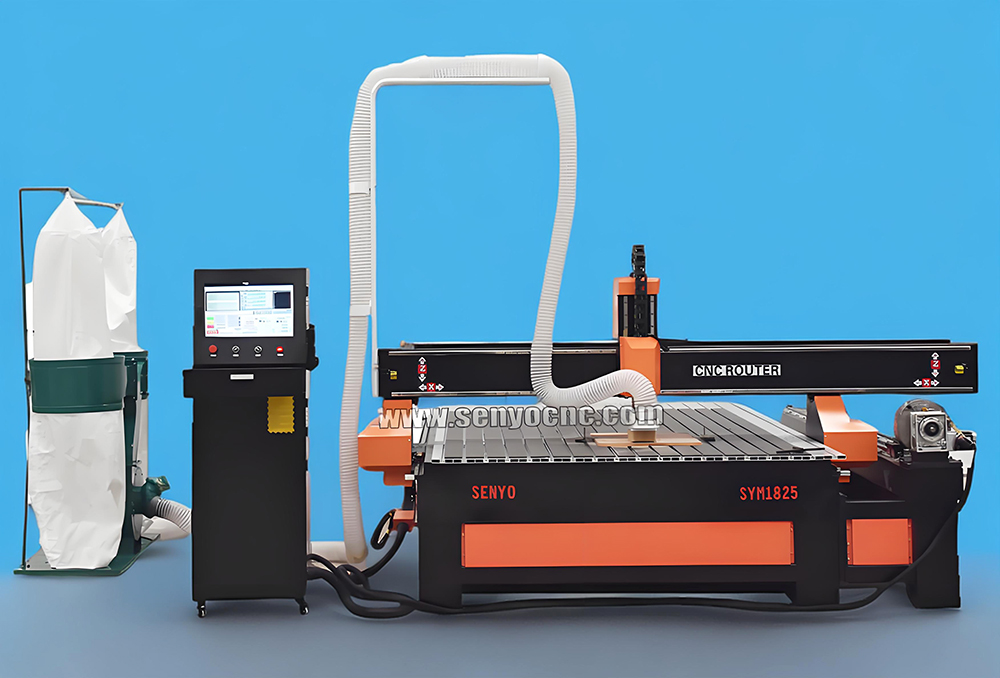

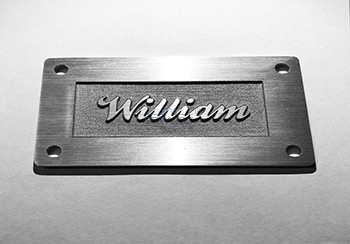

Jacob from United States

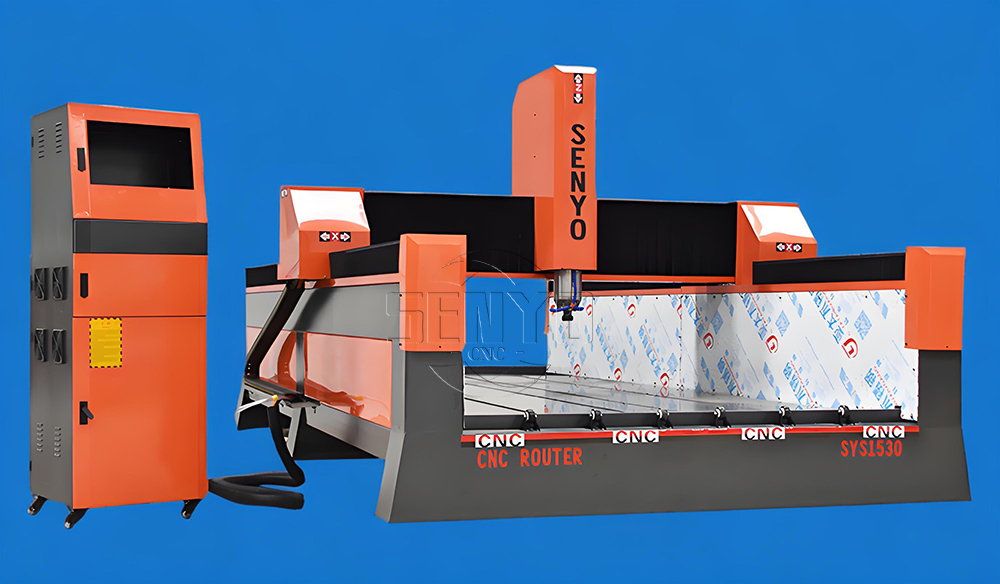

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

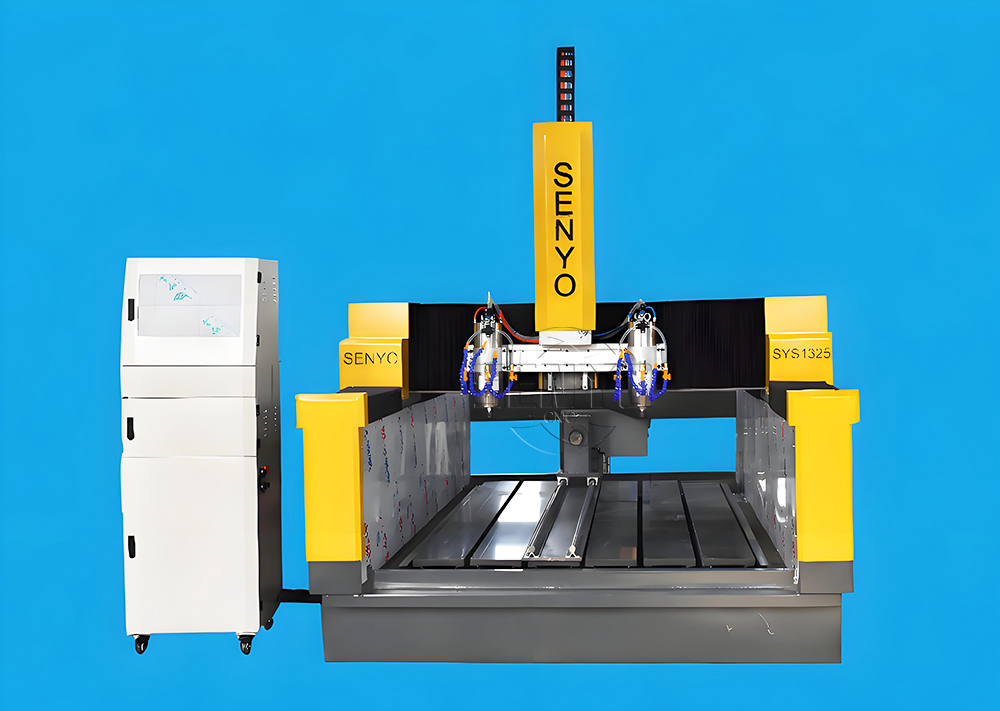

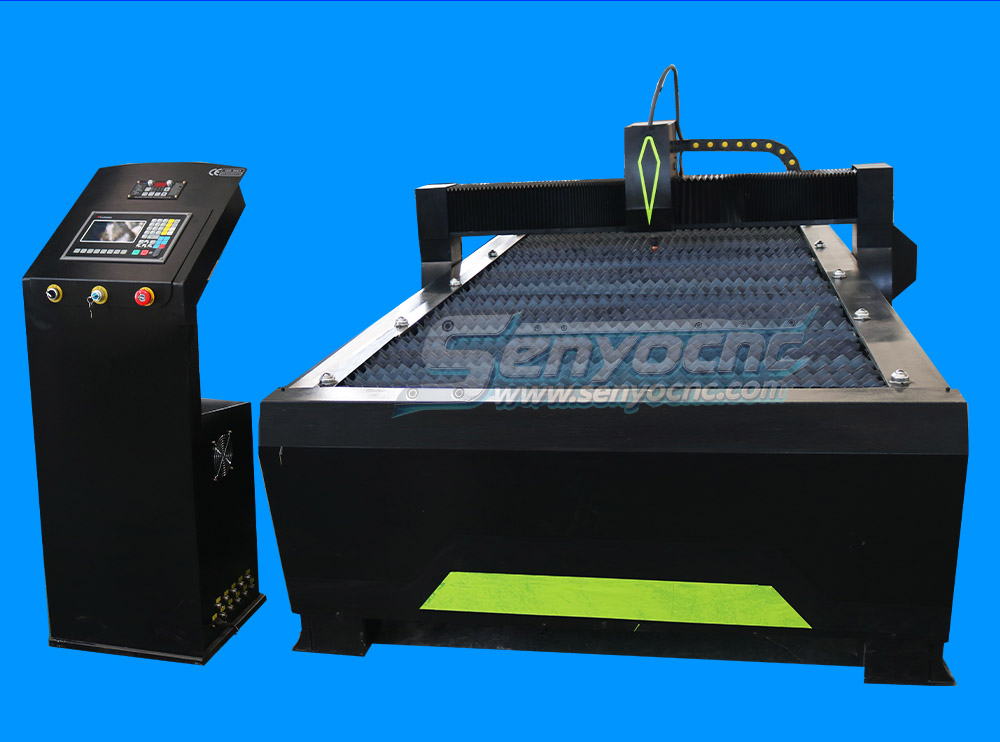

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

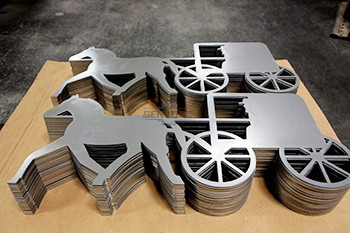

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

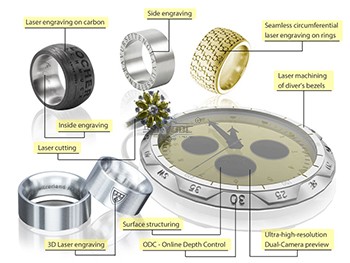

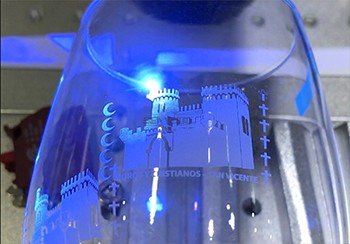

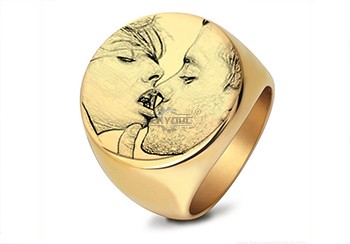

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

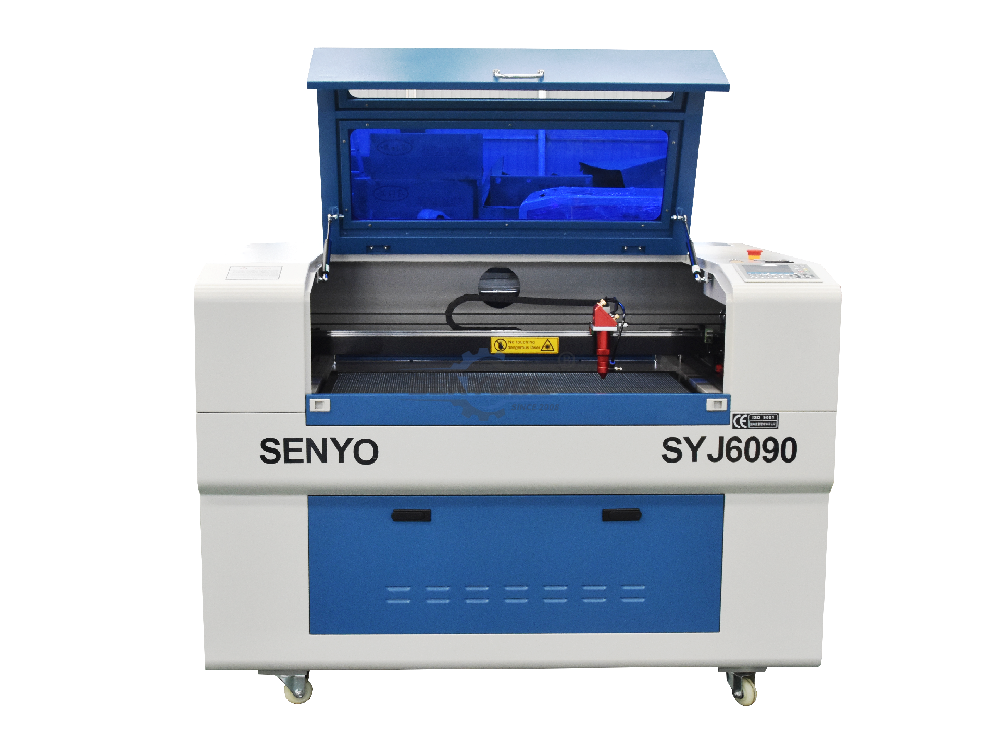

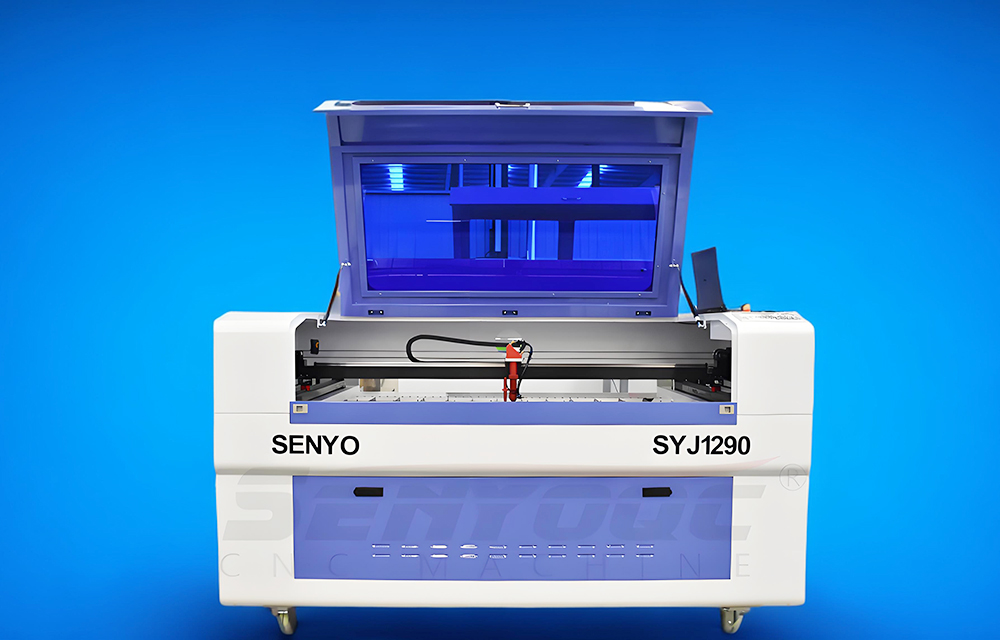

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344