How Does a Wood Copy Machine Work?

The basic working principle of a wood copy machine is simple: it uses a template (or pattern) to guide the cutter as it mills, routers, or shapes the wood.

Here’s how it works step-by-step:

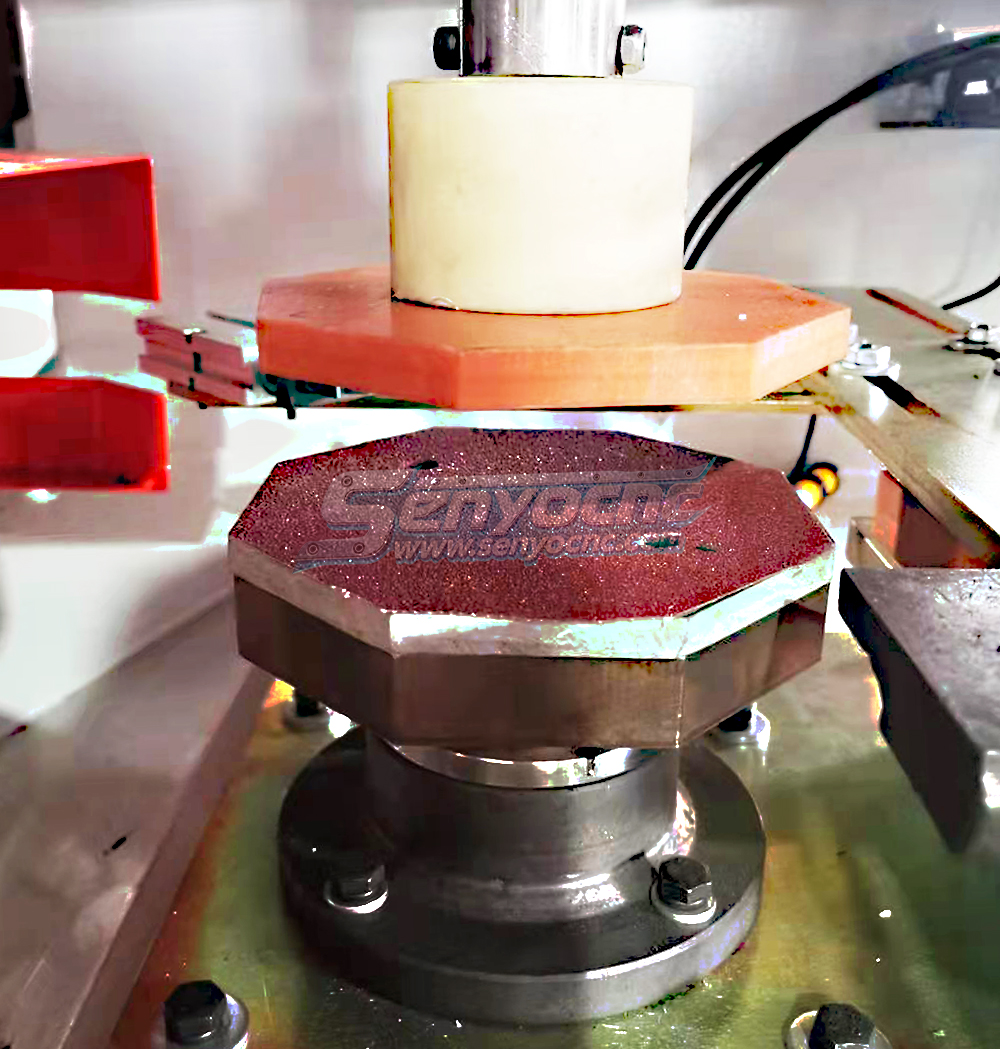

1. Template Setup: A template or pattern is created that holds the desired shape or design. This can be a physical model of the object you wish to replicate, such as a decorative carving or a part of furniture.

2. Placement of Workpiece: The wood piece to be copied is placed securely on the machine bed or working surface.

3. Cutter/Router Guidance: The machine’s cutter or router follows the contours of the template, cutting the wood in the exact shape and size as the pattern. In the case of CNC machines, the machine reads the digital design and replicates it with high precision.

4. Repeatability: The major advantage of wood copy machines is their ability to produce the same design over and over again, ensuring consistency and reducing the chance of human error.

Benefits of Using a Wood Copy Machine

1. High Precision

Wood copy machines, particularly CNC models, are known for their exceptional accuracy. Whether you’re working on intricate designs, custom carvings, or furniture parts, these machines ensure that every copy is identical, which is difficult to achieve manually.

2. Increased Efficiency

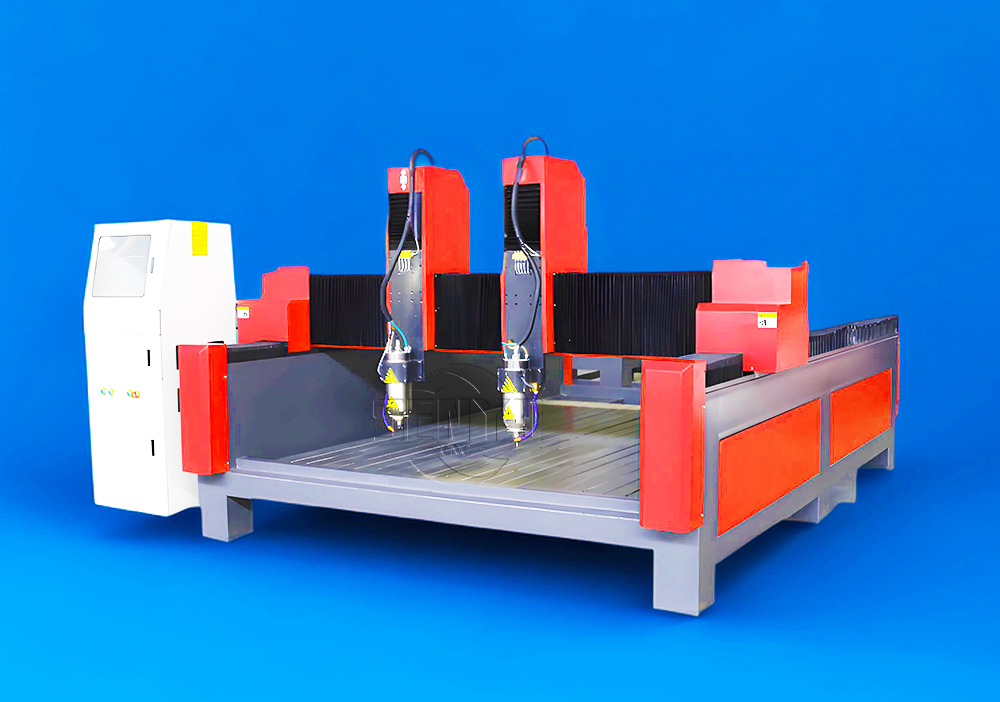

By automating the copying process, wood copy machines can significantly speed up production time. This is especially beneficial for businesses that need to produce large quantities of identical wood pieces, such as cabinet doors, moldings, or custom furniture components.

3. Versatility

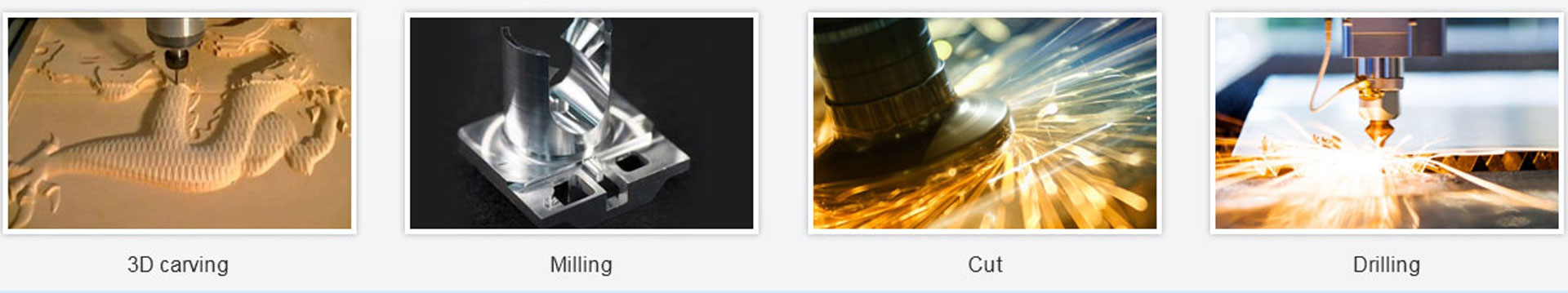

A good wood copy machine can handle various materials, including solid wood, plywood, MDF, and more. It can also be used for a range of tasks, from simple shaping to intricate decorative carving. This makes it a versatile addition to any woodworking shop.

4. Consistency

The ability to replicate exact designs without variation is crucial for industries that demand consistency, such as furniture manufacturing or cabinetry. A wood copy machine ensures that each piece matches the others, making it easier to scale production without quality control issues.

5. Reduced Labor Costs

By reducing the need for skilled manual labor, a wood copy machine can help reduce labor costs. Once set up, these machines operate with minimal supervision, allowing employees to focus on other tasks.

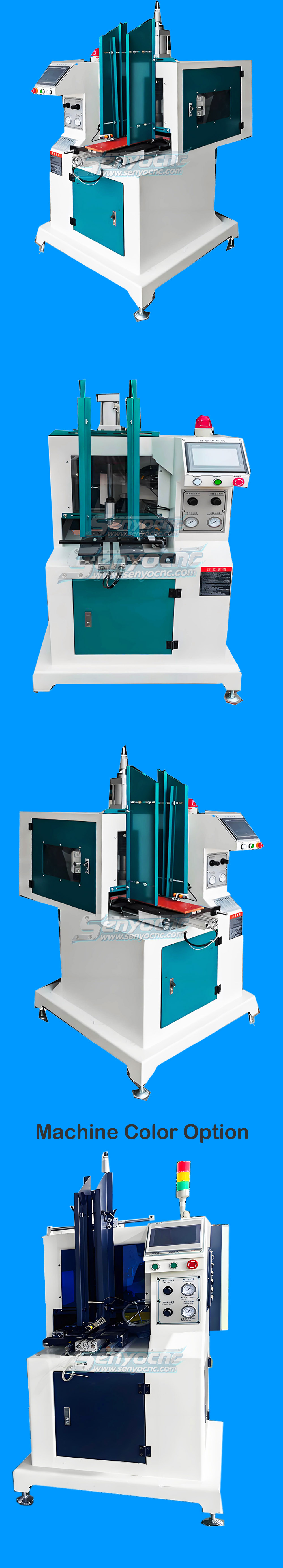

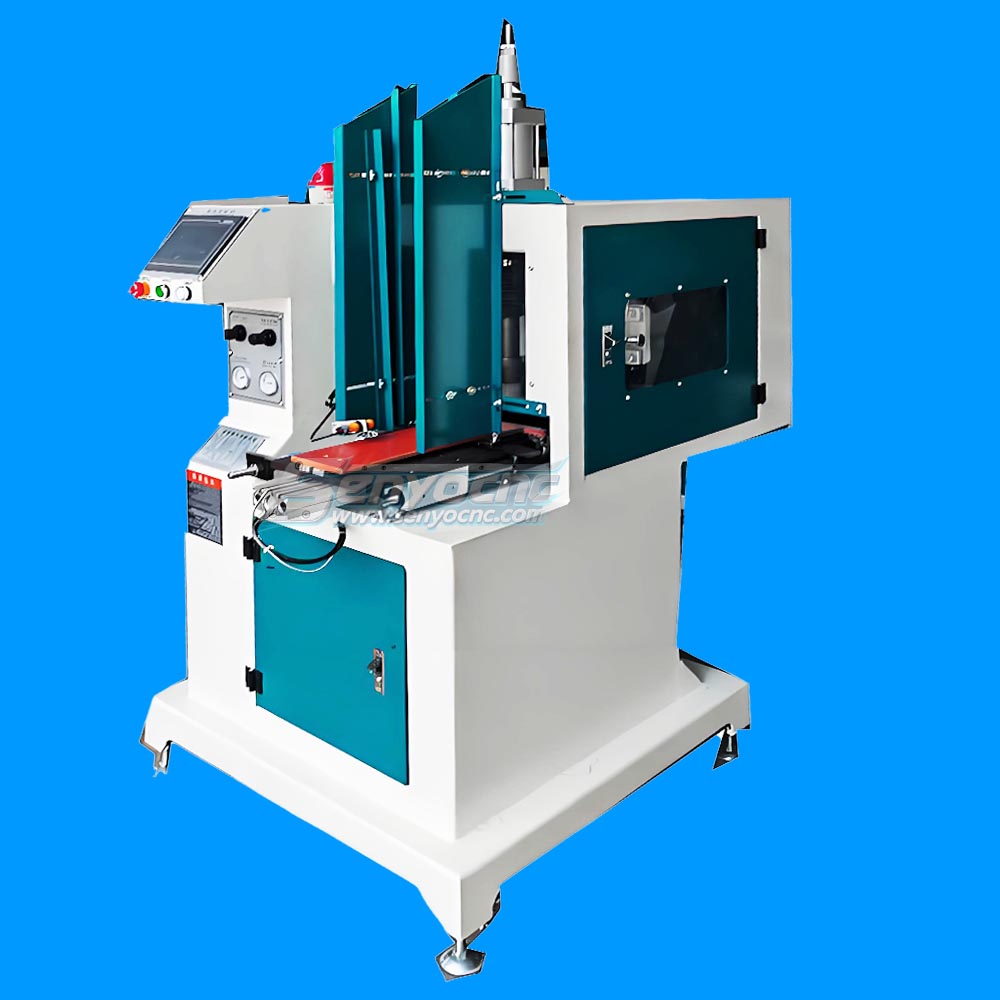

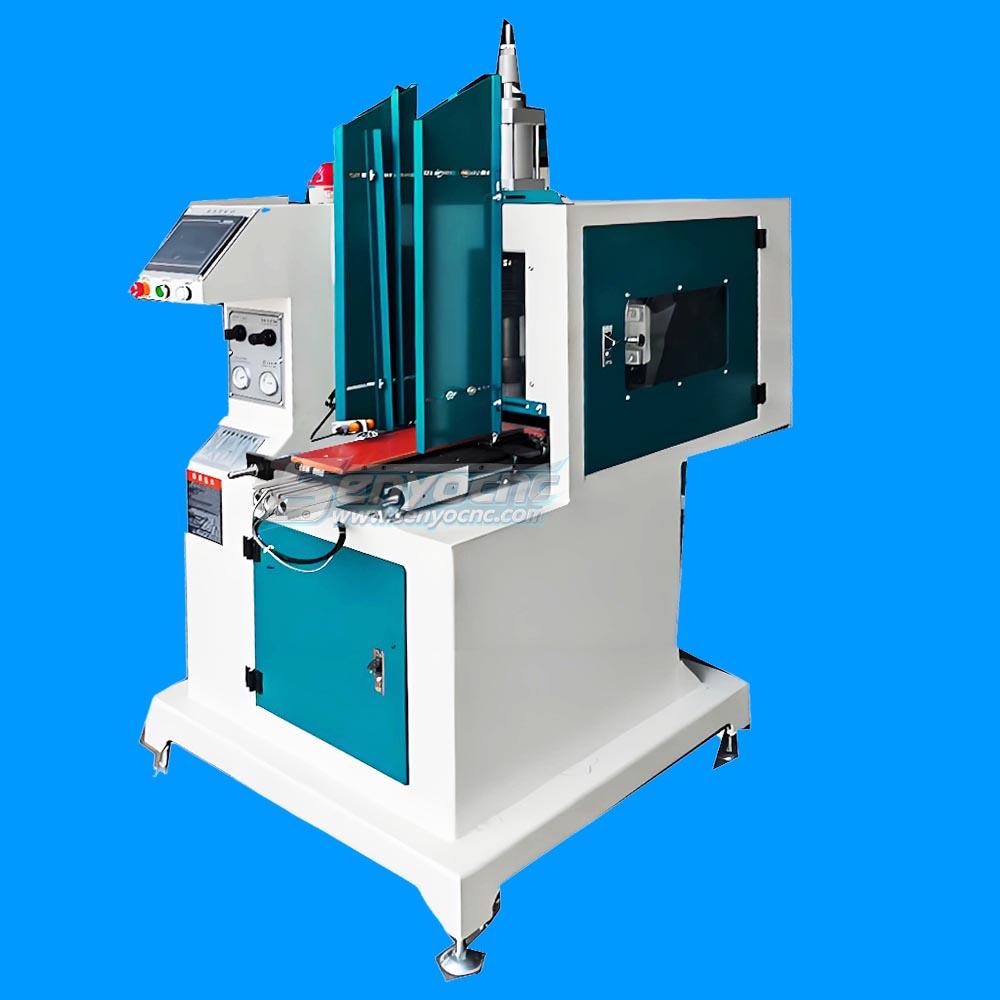

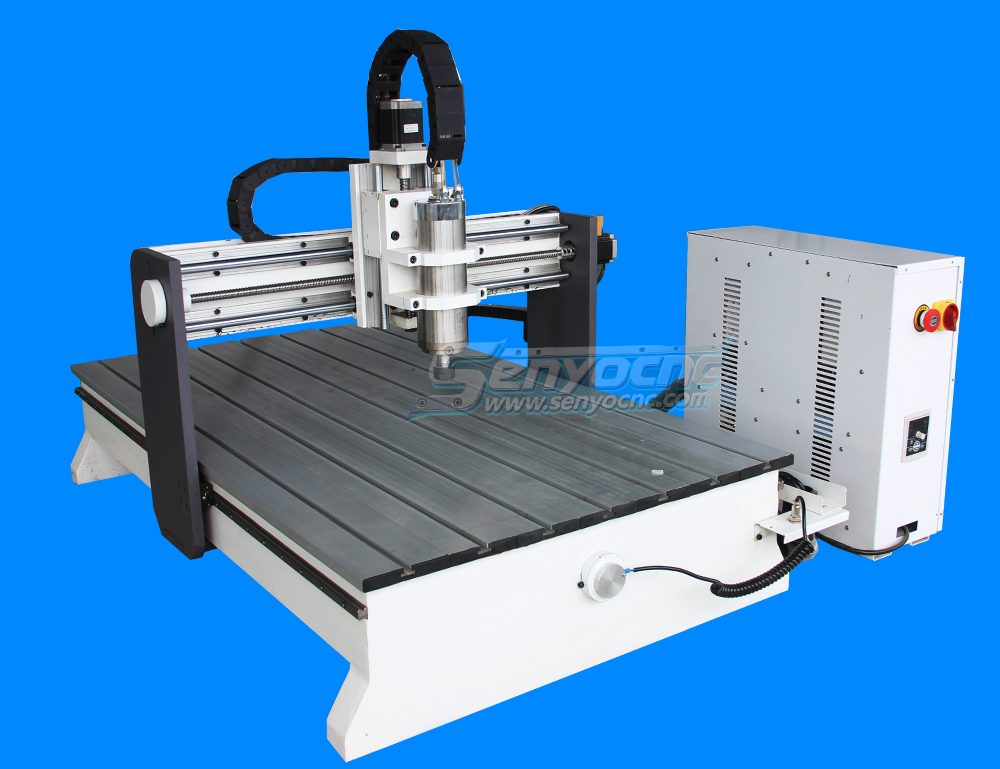

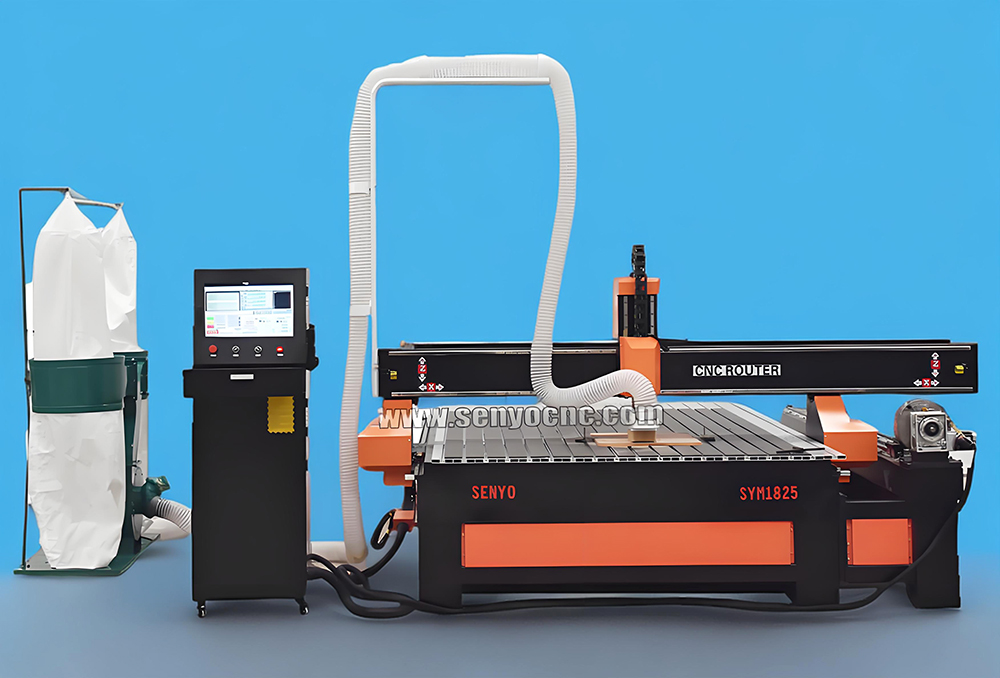

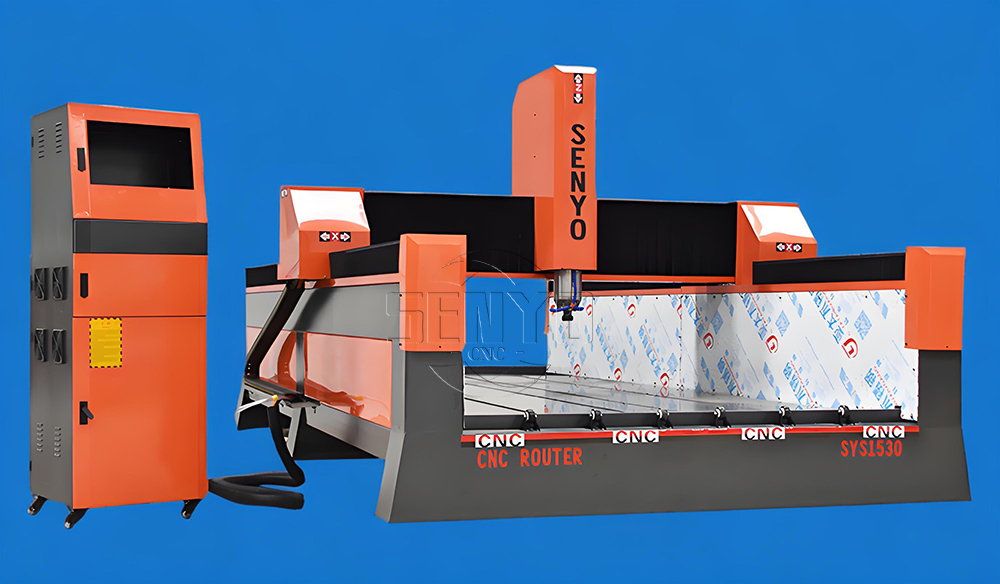

Paramaters

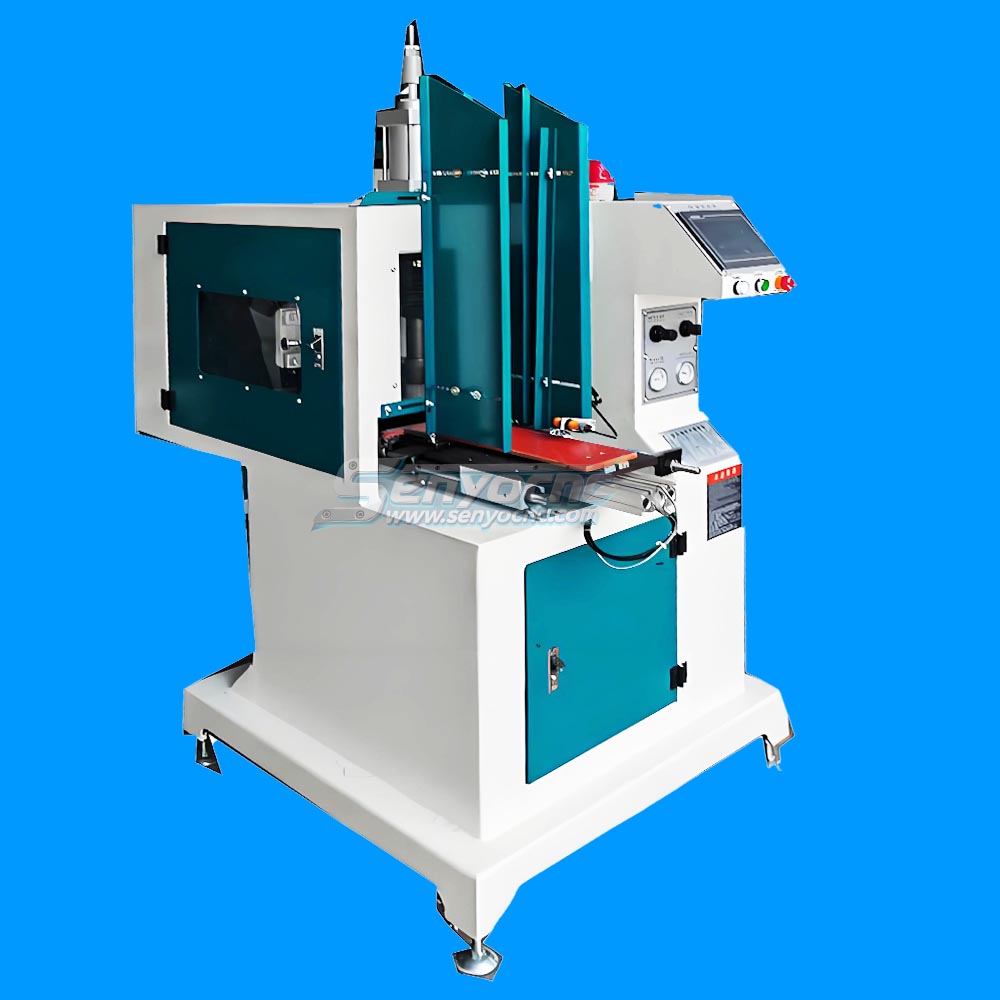

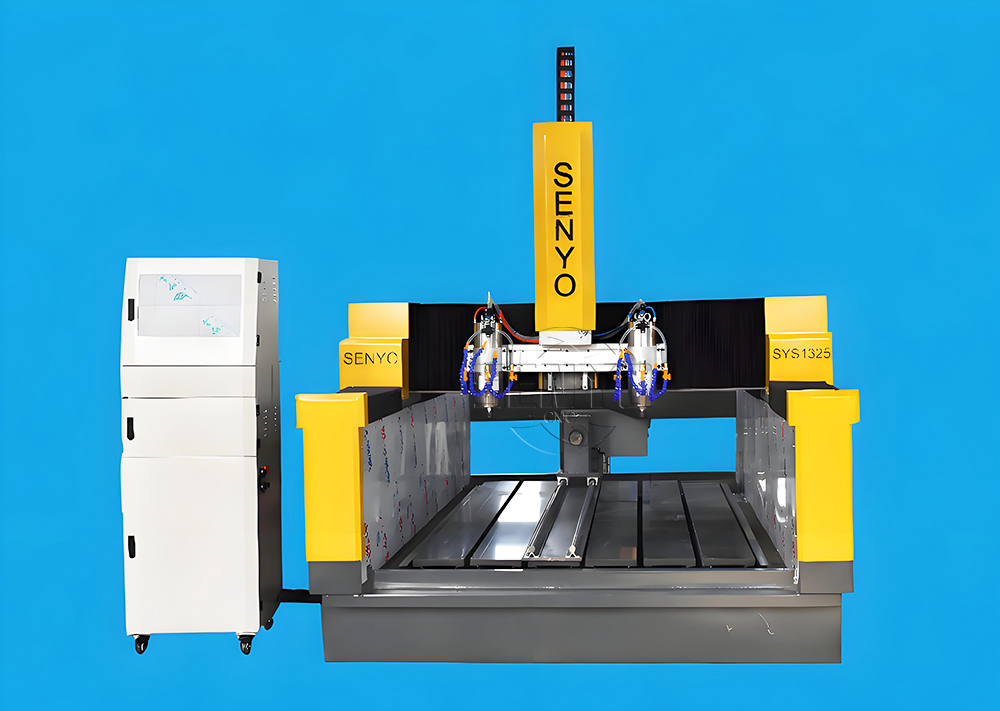

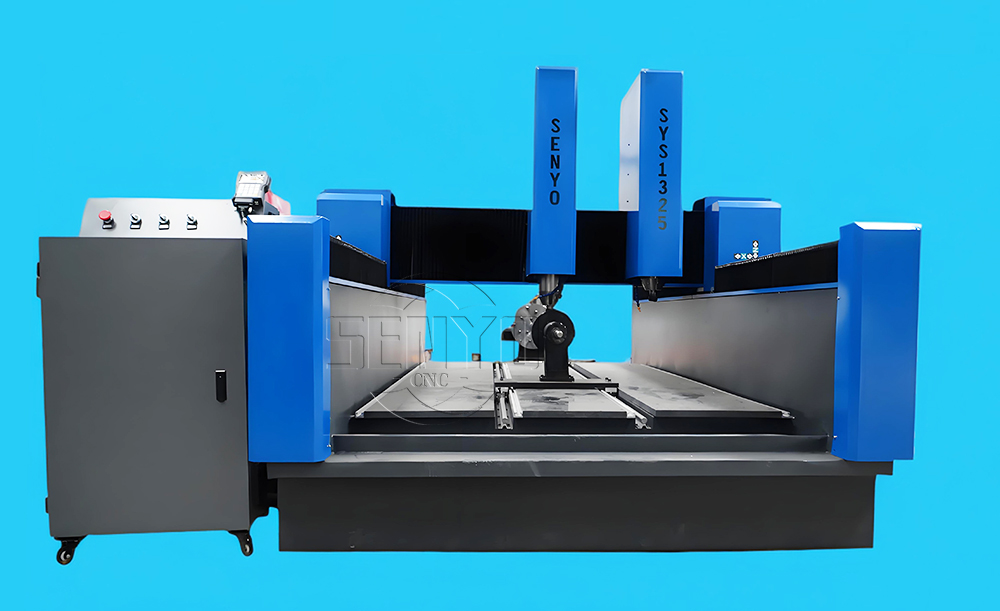

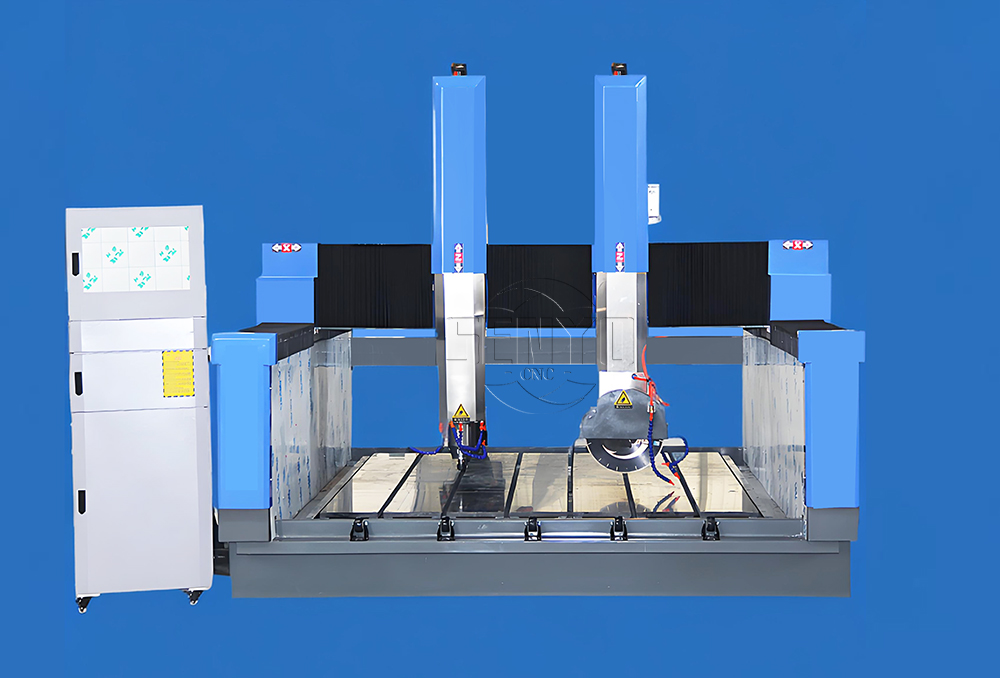

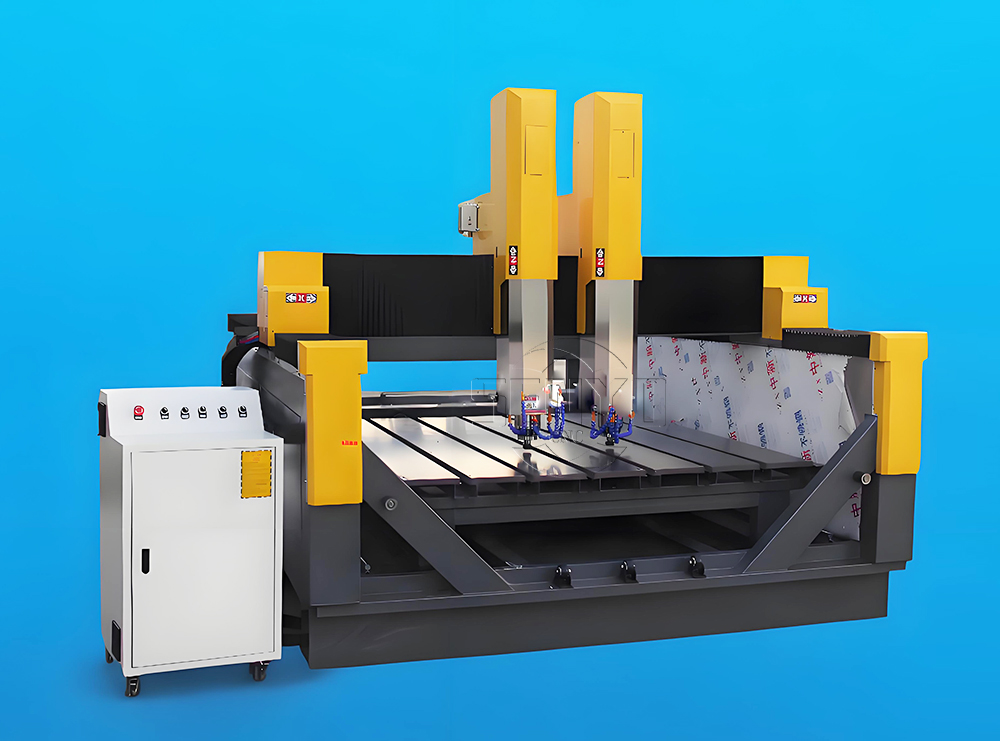

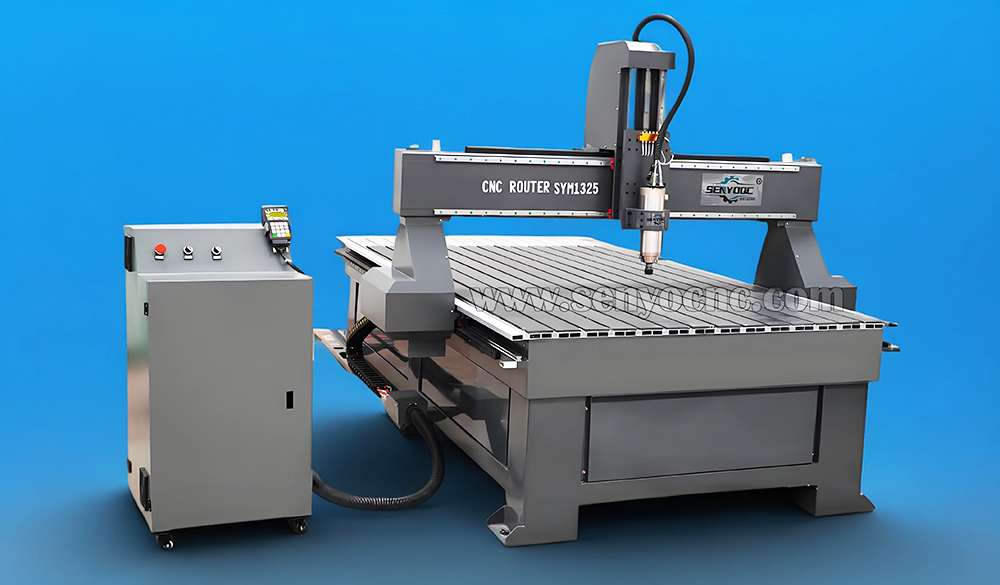

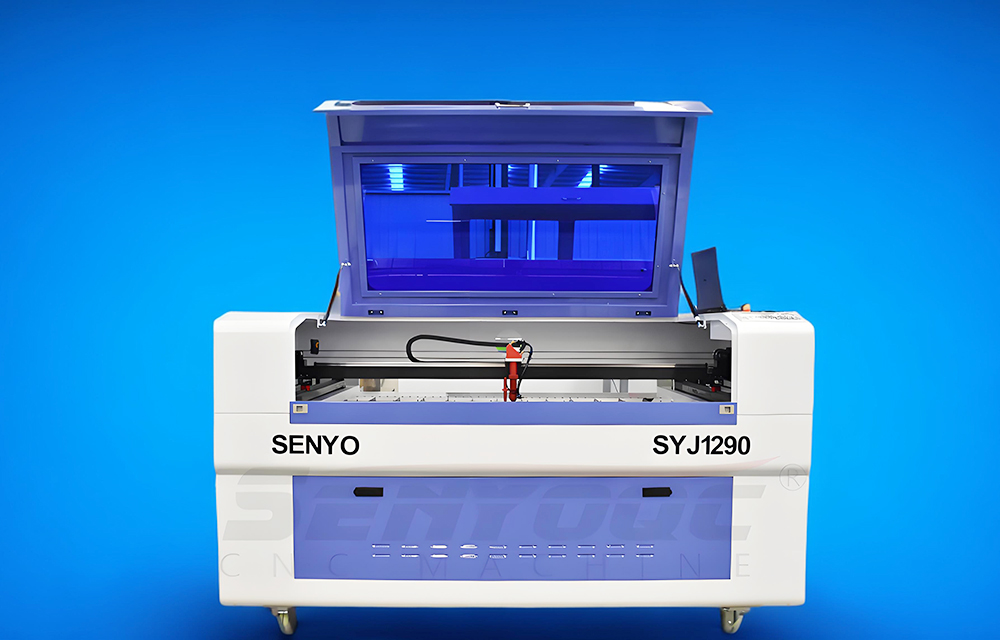

Name:Full automatic CNC engraving and milling | Model:SENYO MX7203 |

Machine size:1100*1000*1750mm | Machine weight:580kg |

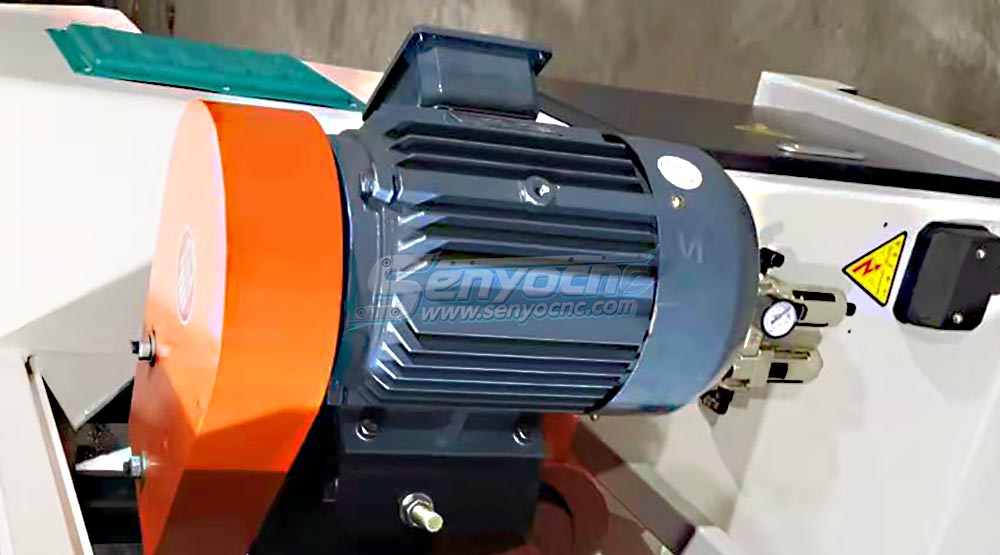

Motor :10kw 380v | Working length:30-200mm(Or custom made ) |

Cutter diameter:20mm (Or custom made ) | Working width:10-150mm |

Working thickness:5-40mm(Or custom made ) | Mainshaft speed:10800r/min |

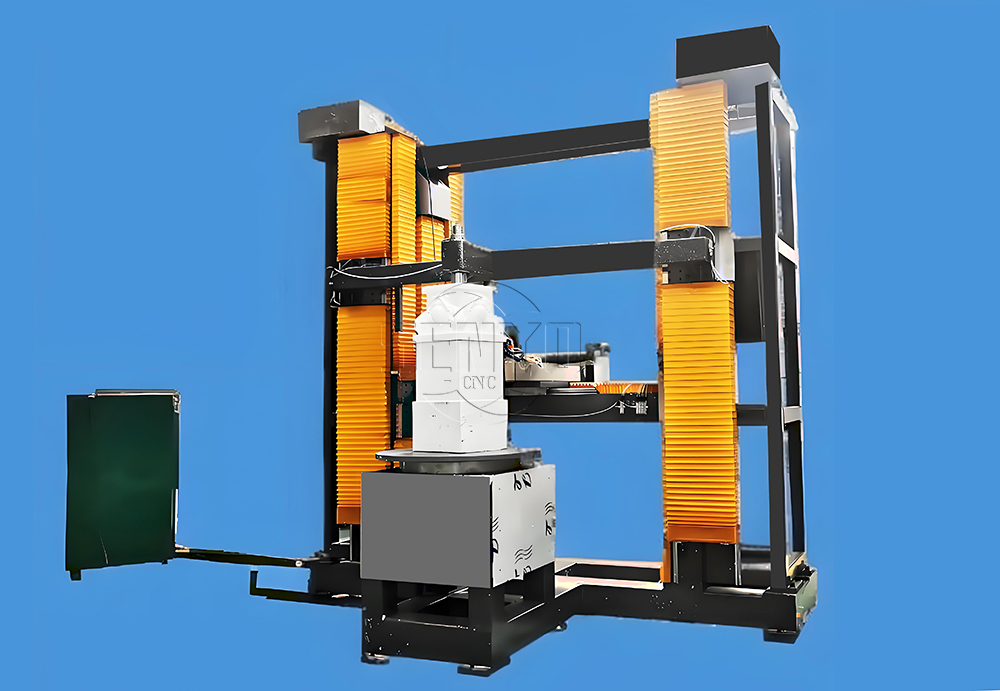

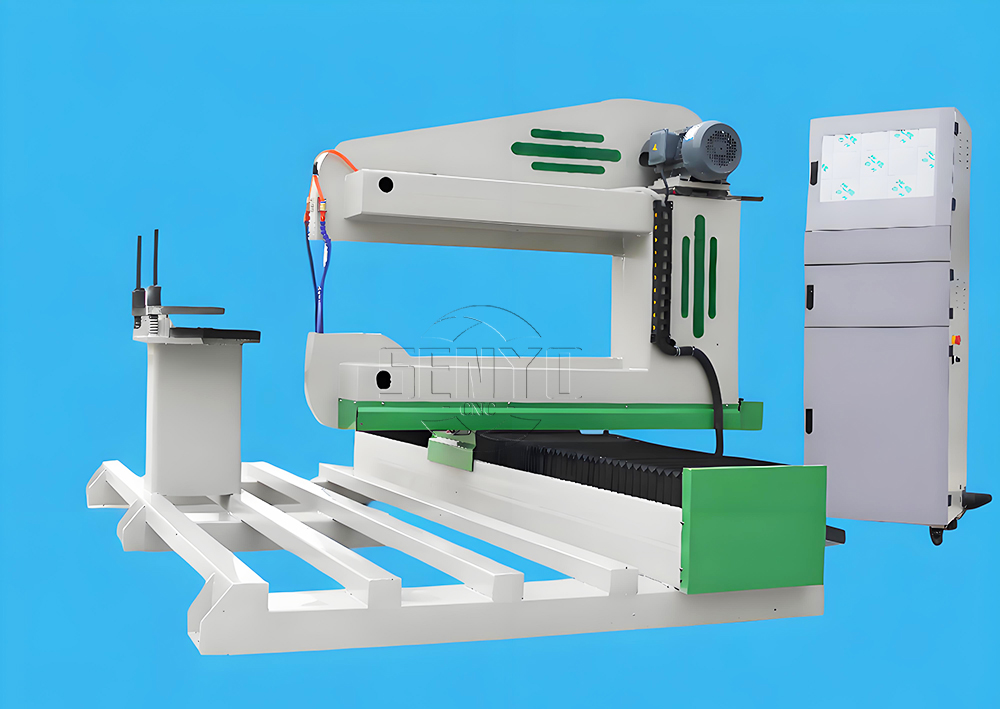

Advantage

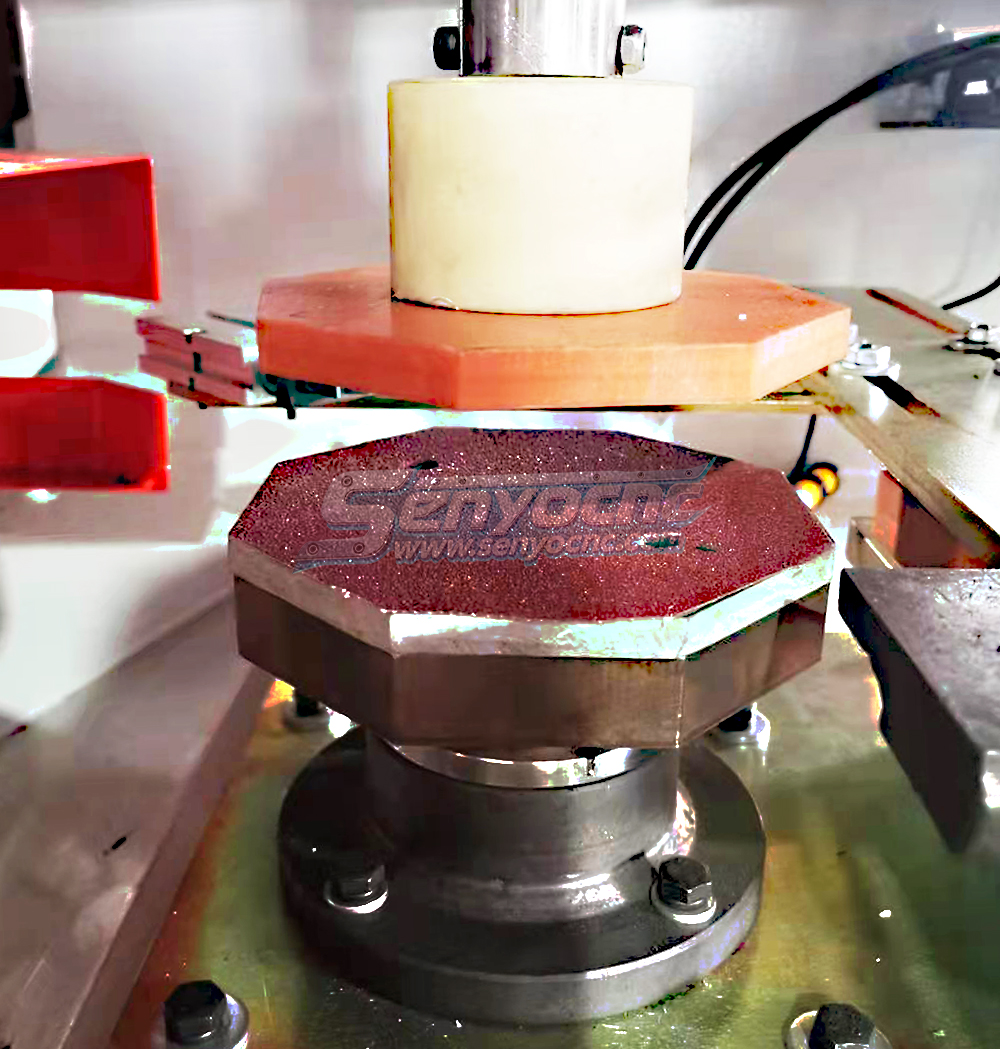

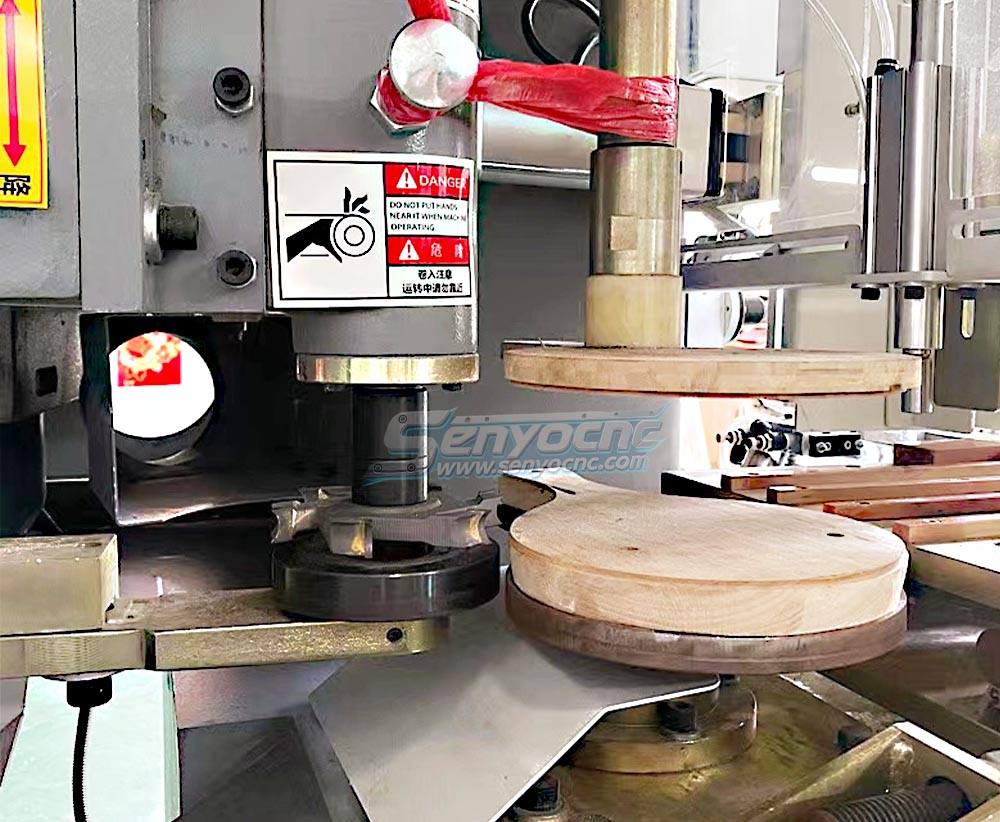

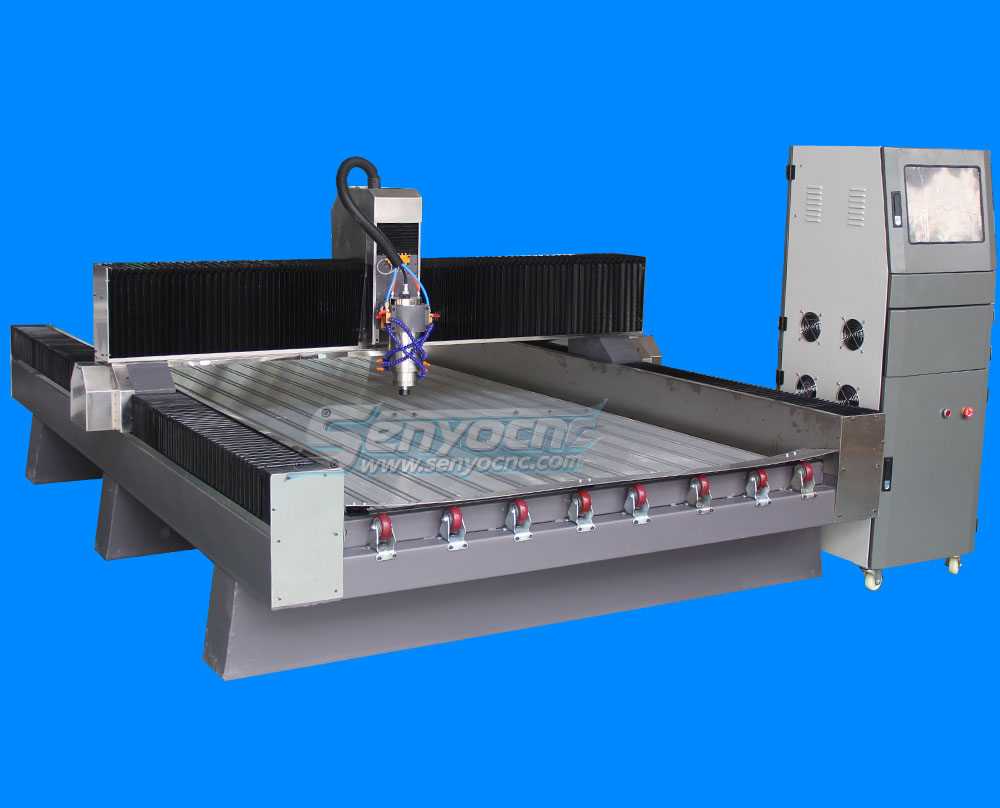

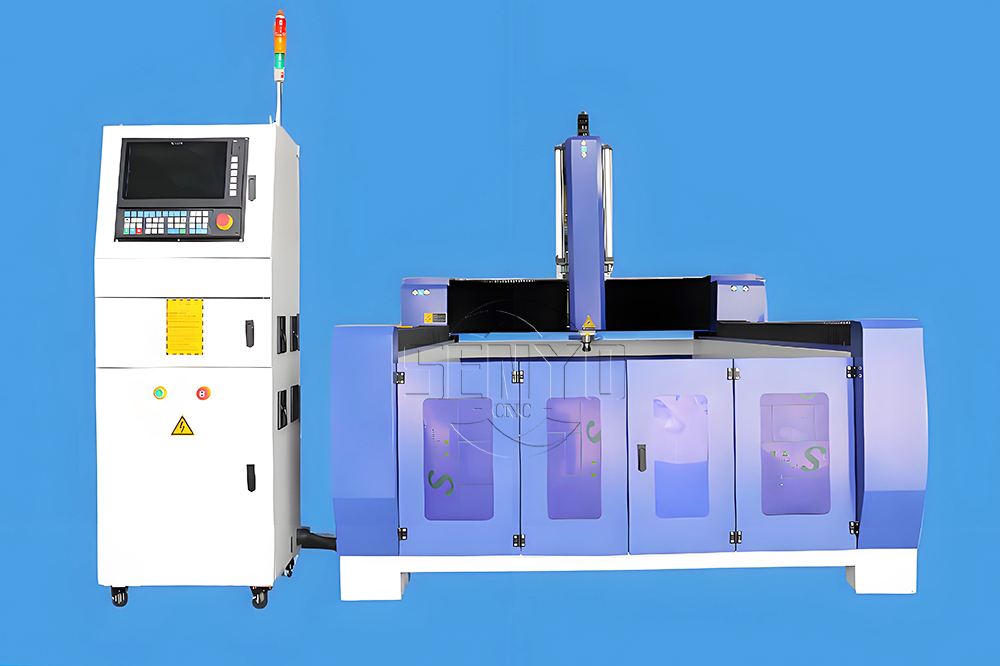

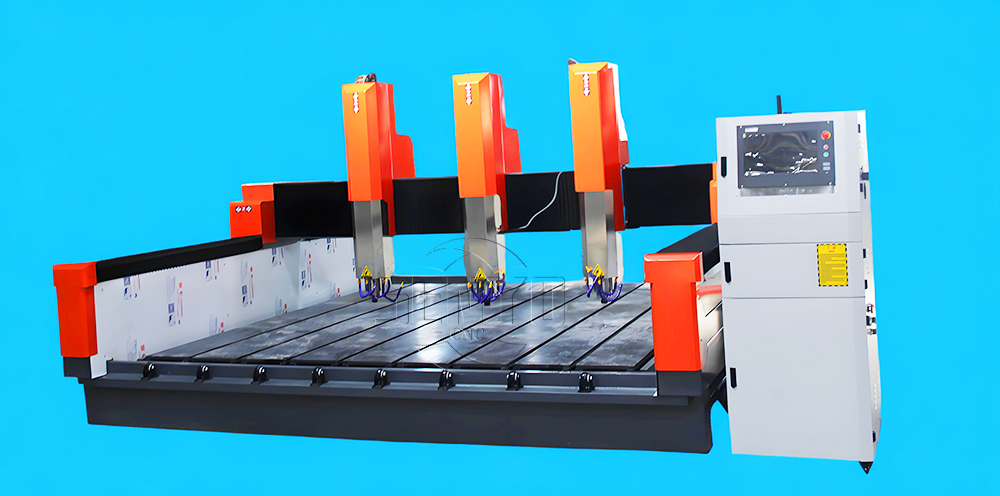

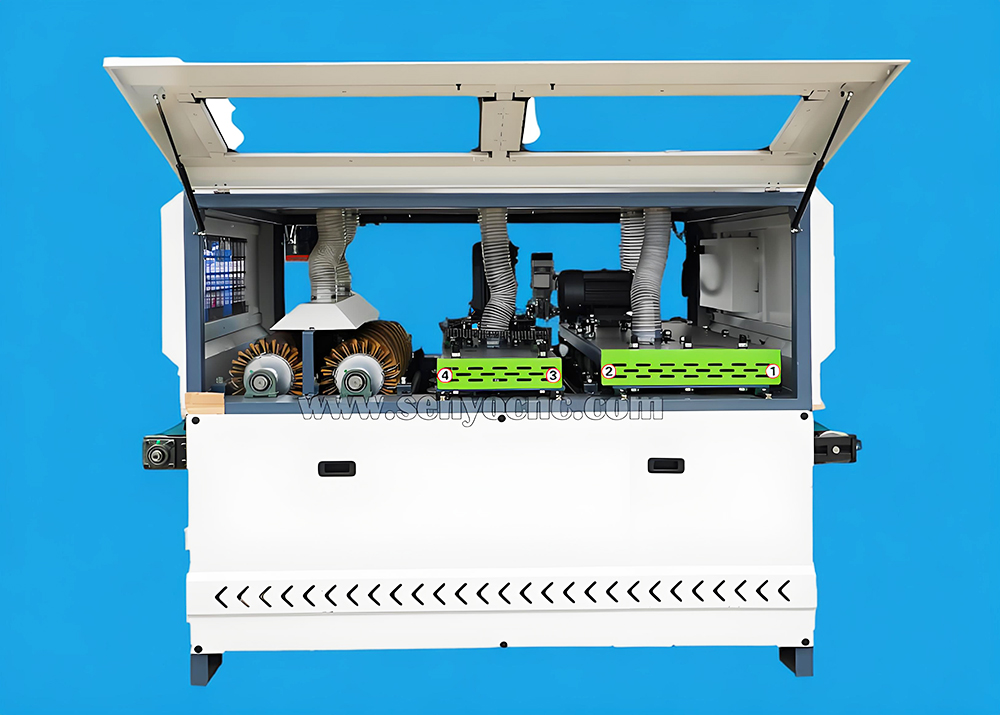

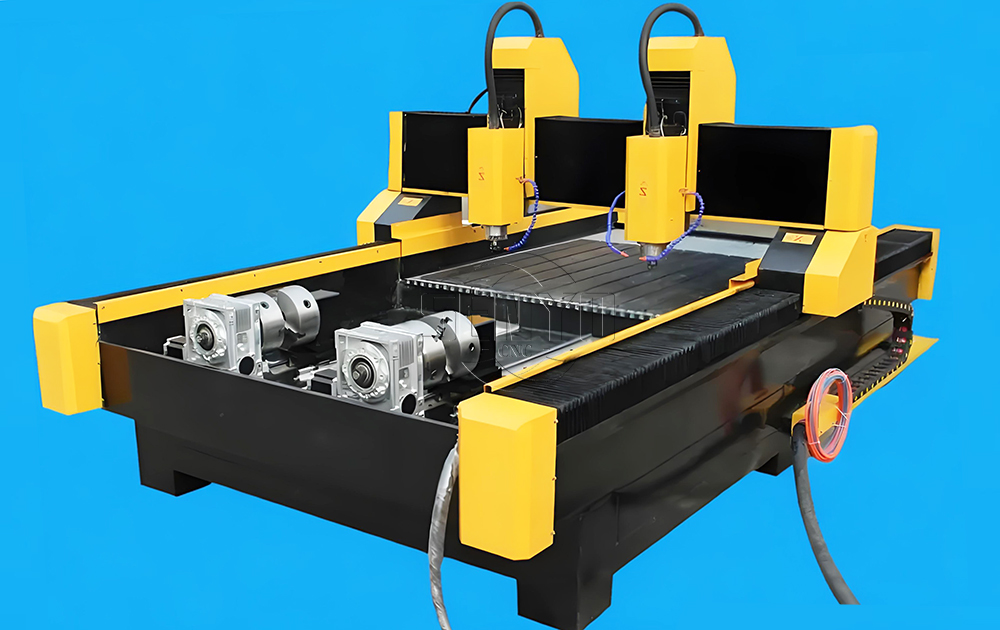

Scope of application: Suitable for bamboo and wood crafts small workpiece round and shaped peripheral copying processing, such as:cup lid, crutch head, brush, knife handle, comb, ice cream spoon and other products processing.

Details:

Fully automatic operation, according to the mold model copying, stable performance, fast processing speed, high accuracy, improve the production force, reduce the production personnel, and greatly reduce workers' industrial accidents. One person can operate 4 machines at the same time, which is more than 20 times more efficient than the traditional process. This machine has been recognized by the wood industry process manufacturers, and is an essential mechanical equipment for process factories

How to Choose the Right Wood Copy Machine

Selecting the right wood copy machine depends on several factors, including the type of work you do, your production volume, and your budget. Here are some key considerations:

1. Type of Work

• For small-scale or custom woodworking: A manual or semi-automatic wood copy machine may be sufficient. These machines are generally less expensive and ideal for small projects.

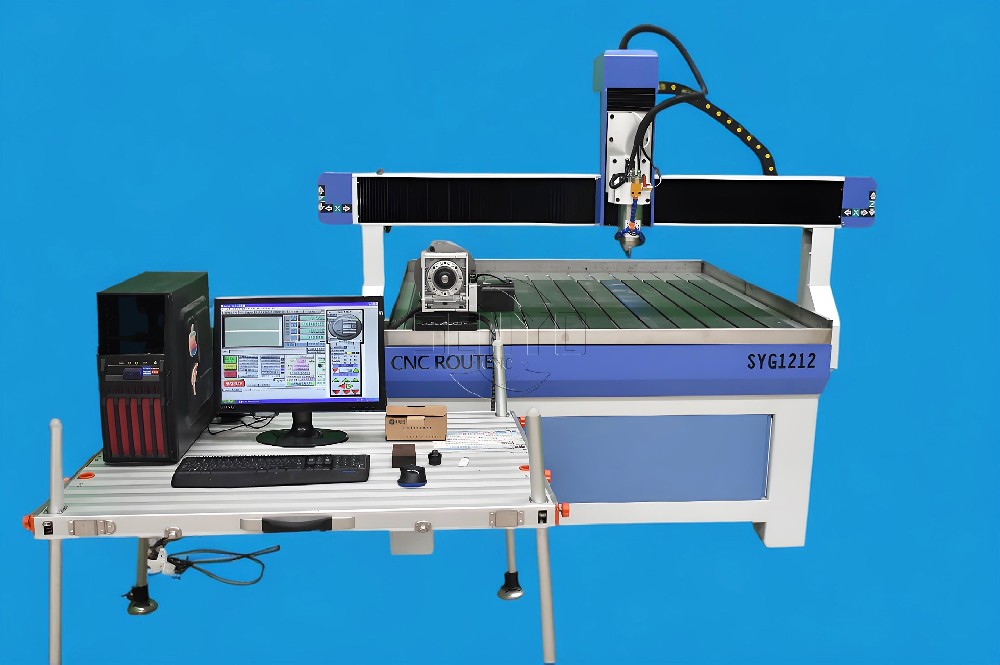

• For large-scale or mass production: A CNC wood copy machine is recommended. It allows for higher precision and the ability to replicate complex designs quickly and accurately.

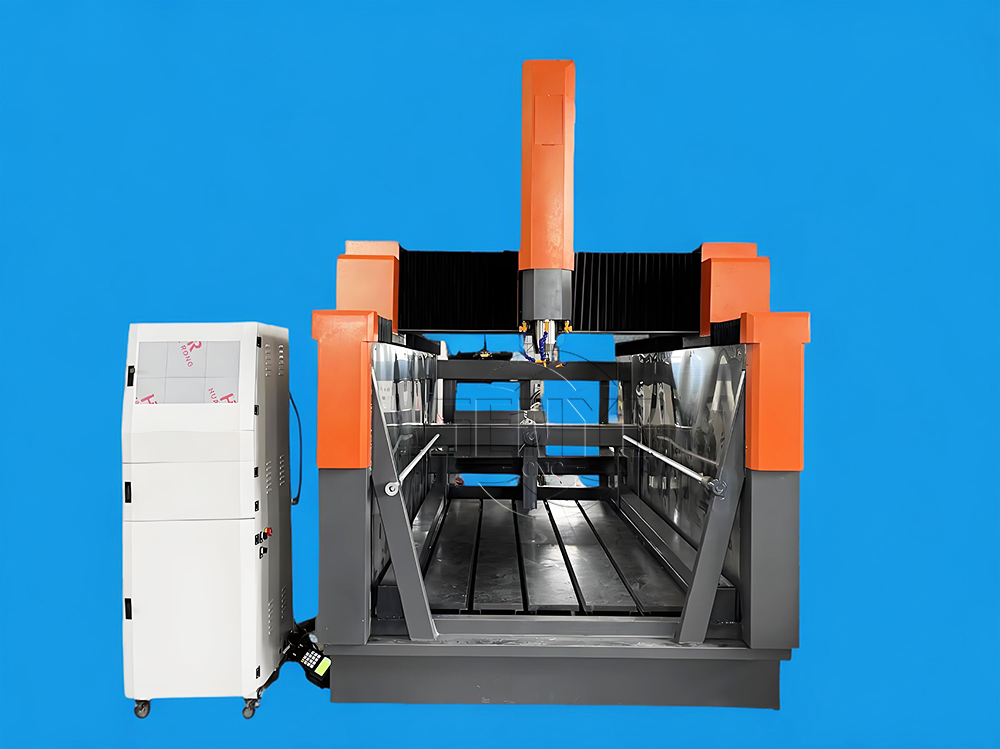

2. Size and Capacity

Consider the size of the workpieces you typically work with. Ensure the machine’s bed or working area is large enough to accommodate your projects. Some machines are designed for larger items like doors or panels, while others are better suited for smaller components like furniture parts.

3. Automation Features

For more automated features, look for CNC wood copy machines. These machines can be programmed to replicate designs without much manual input, saving time and increasing consistency.

4. Budget

Wood copy machines vary widely in price, from affordable manual models to high-end CNC machines. Determine your budget, keeping in mind both initial costs and ongoing maintenance.

5. Brand and Support

Choose a reputable brand known for durability and high-quality performance. It’s also important to consider after-sales support, such as training, customer service, and availability of spare parts

Conclusion

A wood copy machine is an indispensable tool for any serious woodworker or manufacturer. Whether you’re producing custom furniture, architectural moldings, or decorative carvings, having the right equipment can make all the difference in terms of quality and efficiency. By understanding the different types of wood copy machines, their benefits, and how to choose the best one for your needs, you can significantly improve your woodworking projects and grow your business.

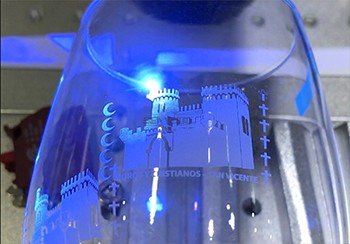

Machine Application Work Show

Packaging Details

• Outside package: Standard marine export plywood case.

• Inner package: Stretch film and plastic film for humidity.

We can package according to your requests.

Warranty And Service

• 24 months whole machine warranty and maintenance for a lifetime.

• Free installation and testing before shipping and free training for operators

• Advice for the best CNC solutions for customer's requirements.

• Free training and sample making.

• 7/24 free service and support.

1. Wood copy machine

2. Woodworking copy machine

3. Wood pattern copying machine

4. Wood profile copying machine

5. CNC wood copy machine

6. Woodworking template machine

7. Copy milling machine for wood

8. Wood carving copy machine

9. CNC wood profiling machine

10. Automatic wood copy machine

• Previous: Boost Productivity With 4-Head CNC Wood Router Machine With 4 Rotary Axes

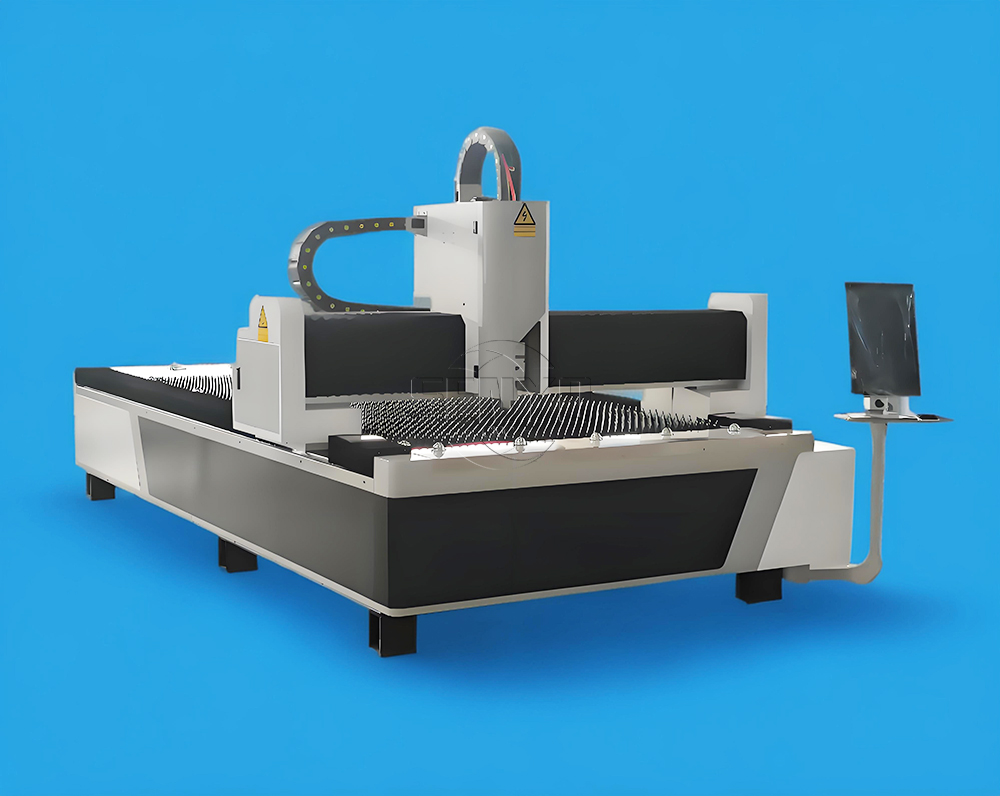

• Next: Industrial 5x10 CNC Router for Aluminum Composite Panels

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

2040 from INDIAN

Best 2040 CNC Router Good Price and Quality ! Thank SENYOQC

10w uv laser from American

Best supplier ! I bought 3 machines for laser and router , thank you Aillen ! --Alec

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

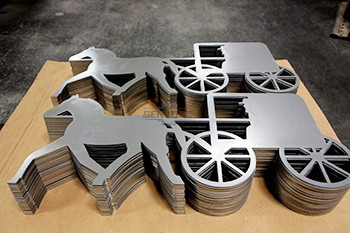

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

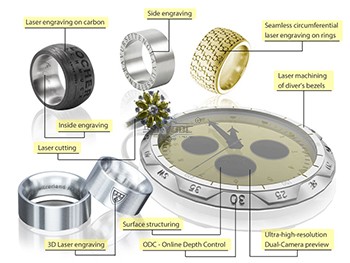

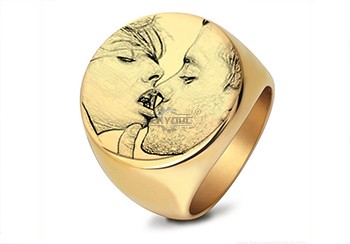

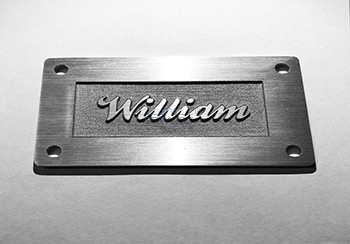

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344