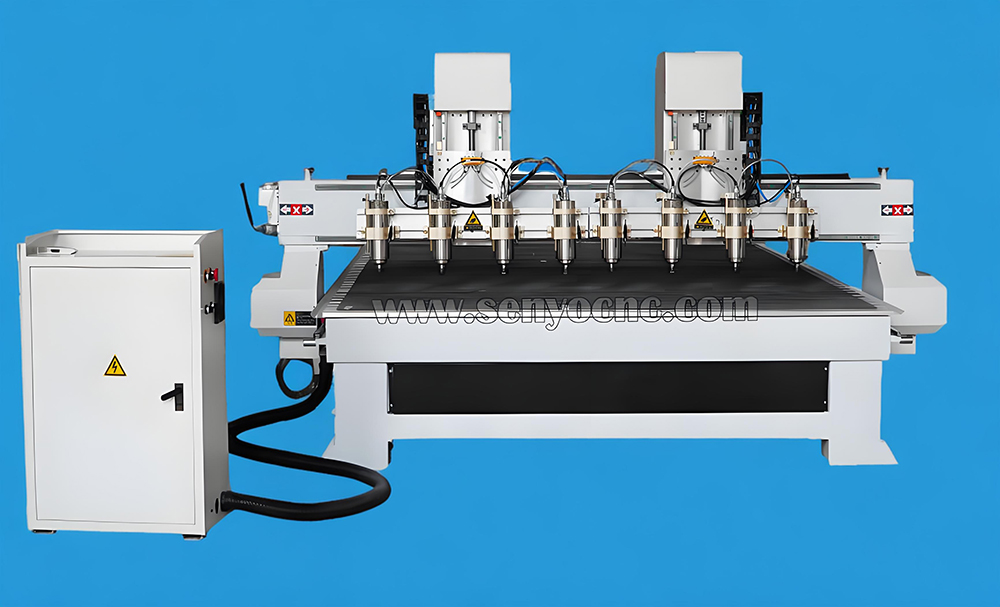

The Industrial 5x10 CNC Router is a reliable instrument for precisely cutting, shaping, and sculpting aluminum composite panels (ACP). It is perfect for enterprises that are involved in interior design, architectural cladding, and sign-making because of its broad work area and ability to handle demanding jobs. These devices save material waste and labor expenses by providing automated and effective panel processing.

Aluminum composite panels are popular due to their strength, lightweight design, and versatility; nonetheless, precise cutting equipment are required while working with them. The smooth operation and flawless edges of the 5x10 CNC router, even on elaborate designs, simplify difficult tasks. For big projects, productivity is increased by huge sheet sizes and quick processing speeds.

A 5x10 CNC router can significantly boost productivity in any type of industry, including manufacturing, signage, and construction. Businesses can easily fulfill manufacturing timelines, minimize errors, and create custom designs because of their adaptability.

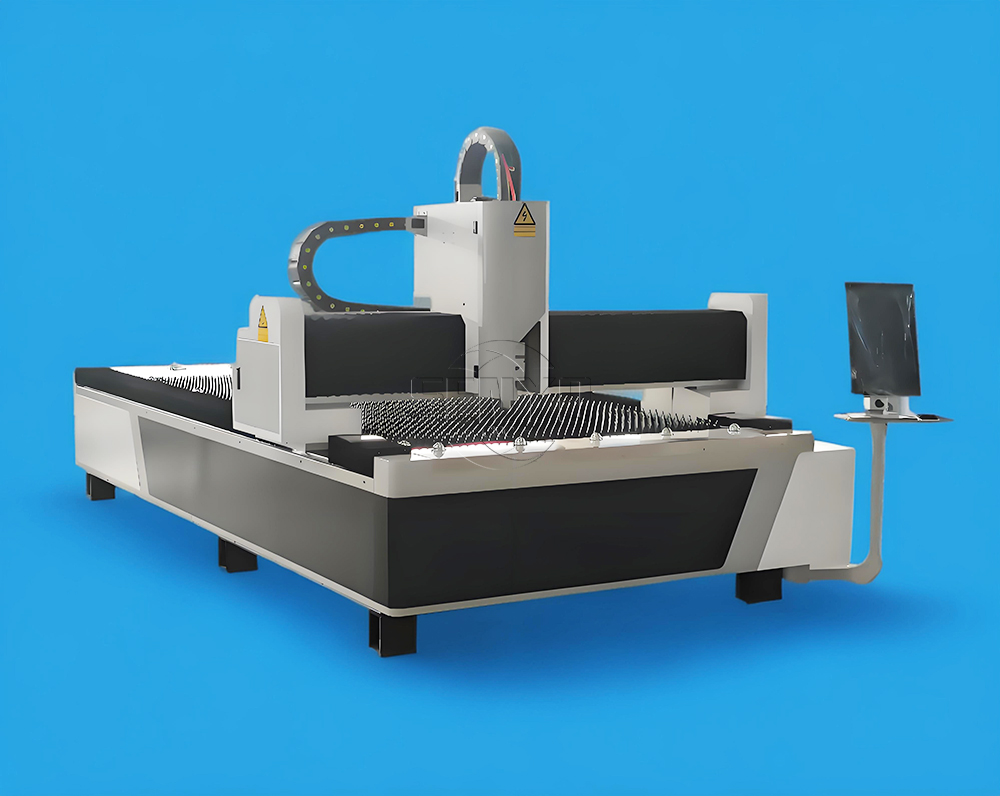

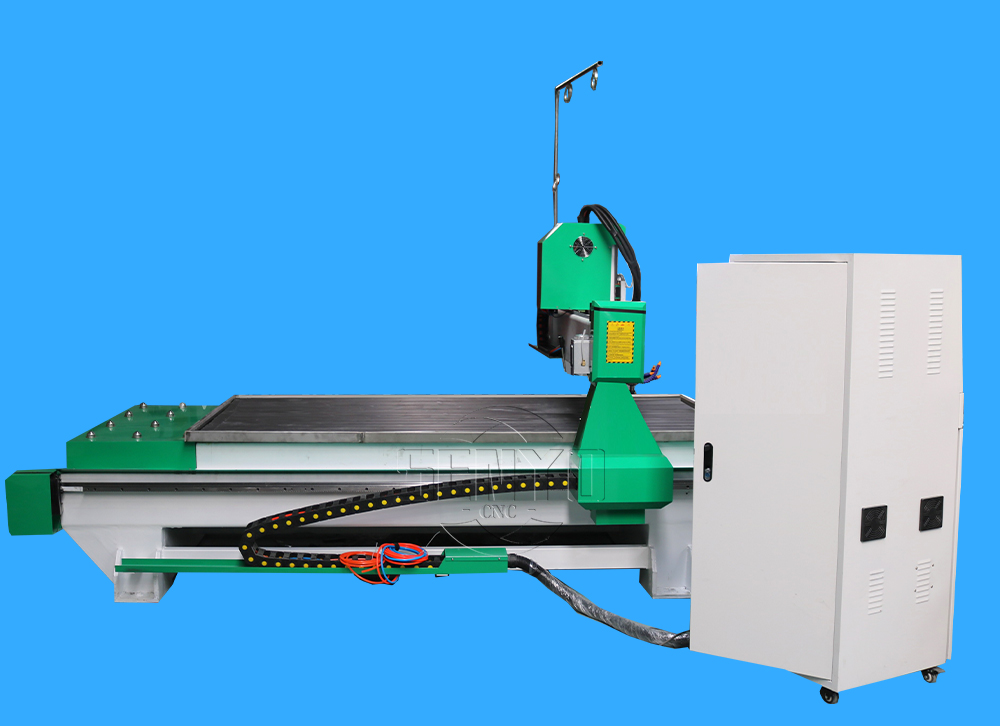

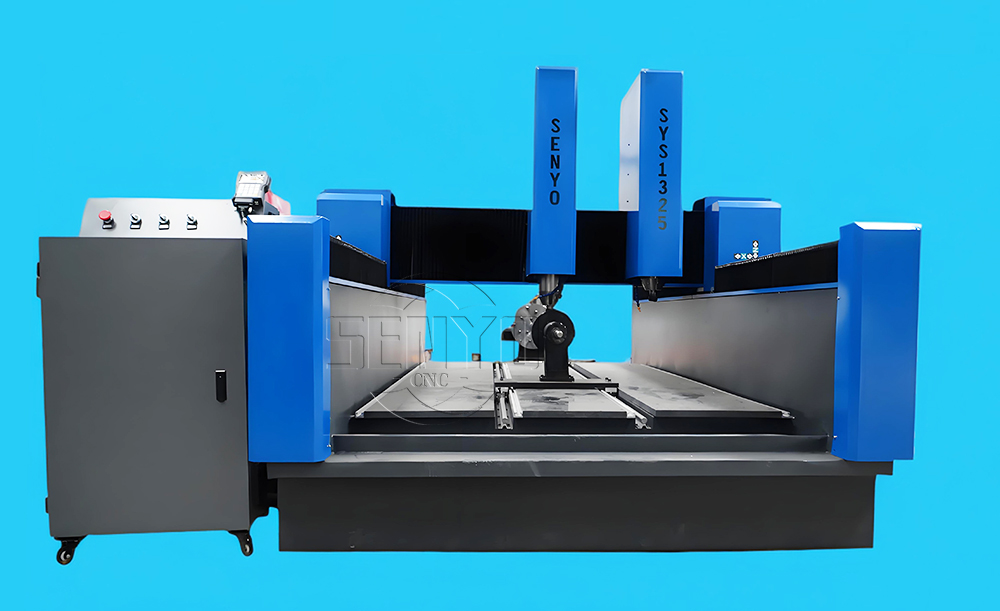

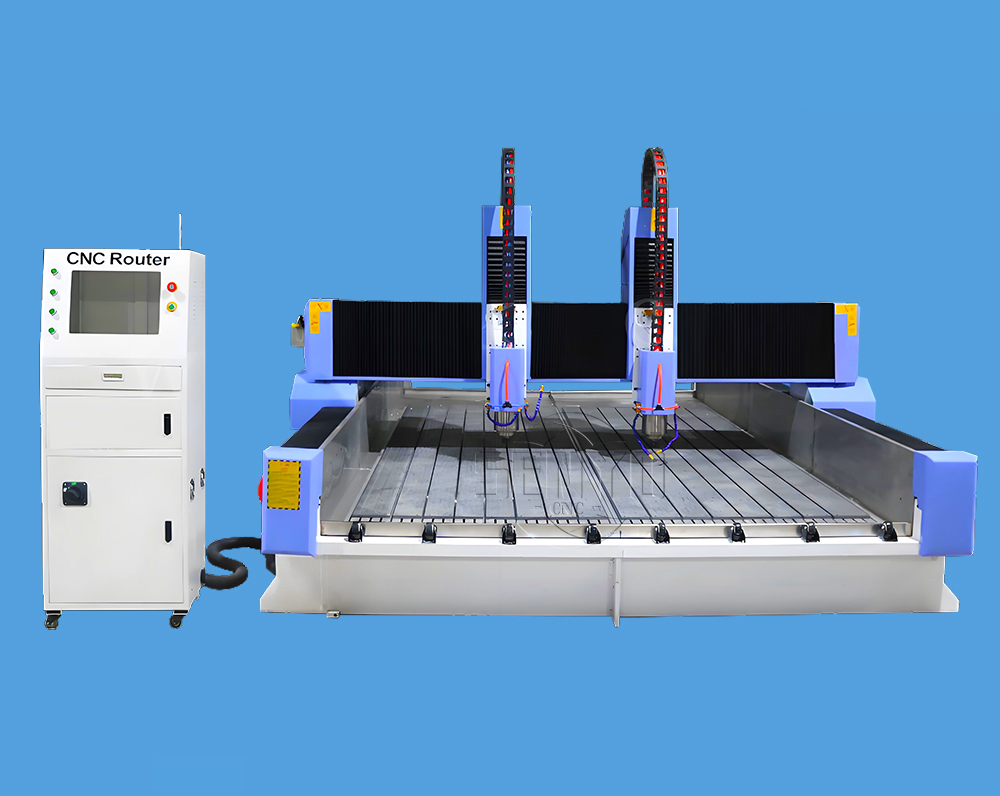

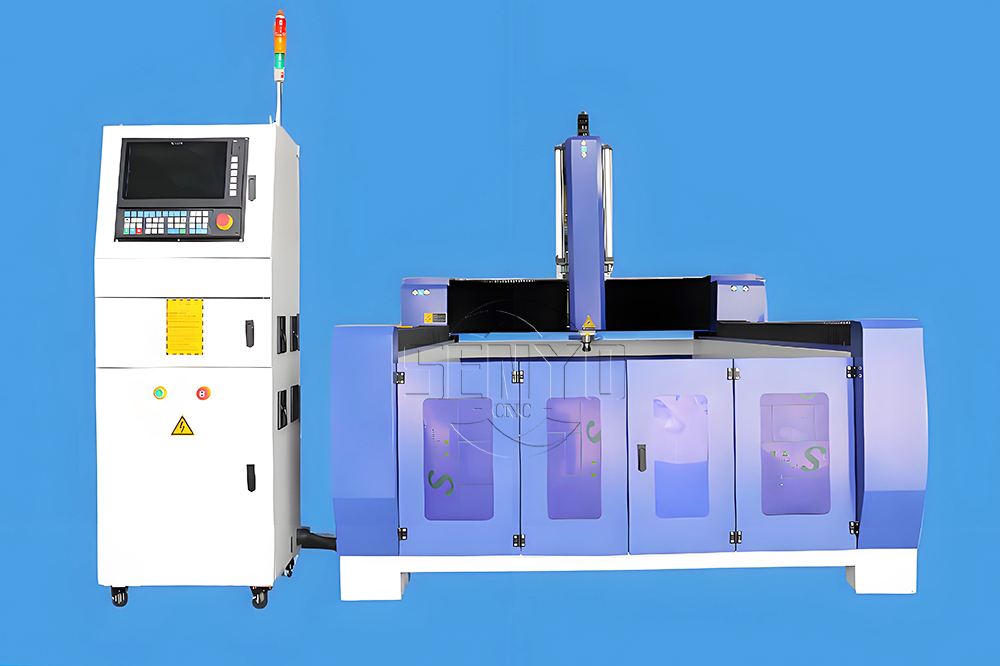

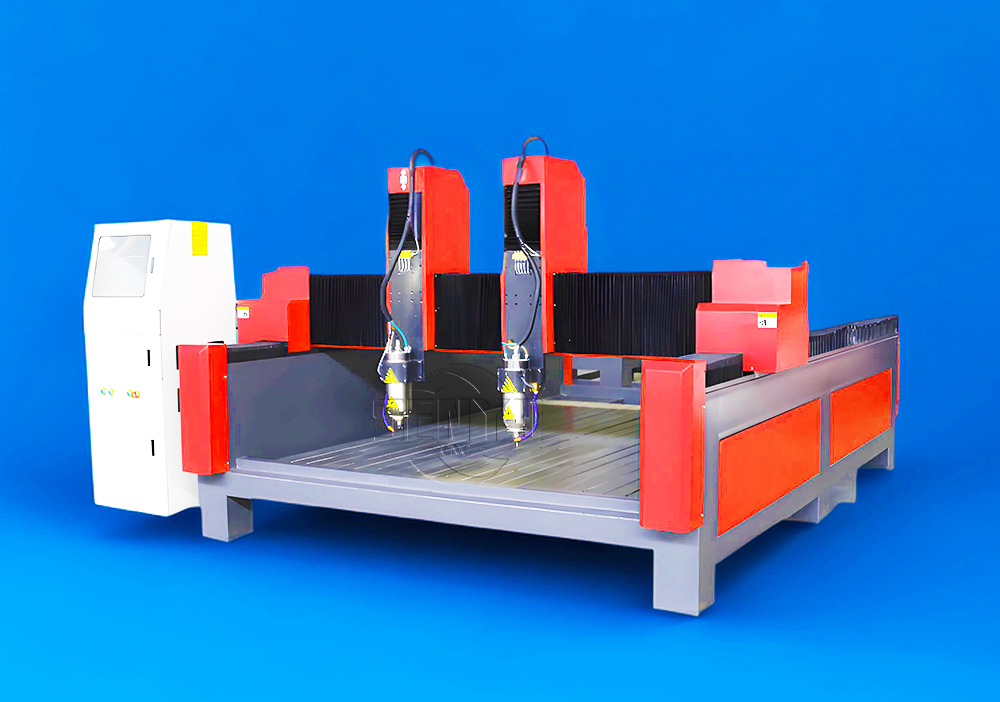

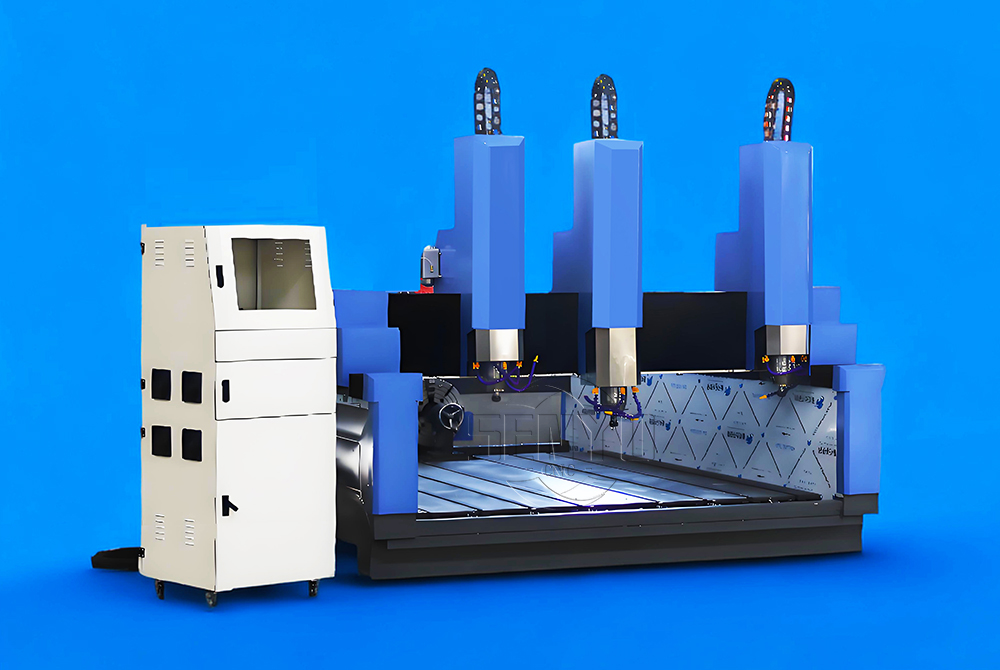

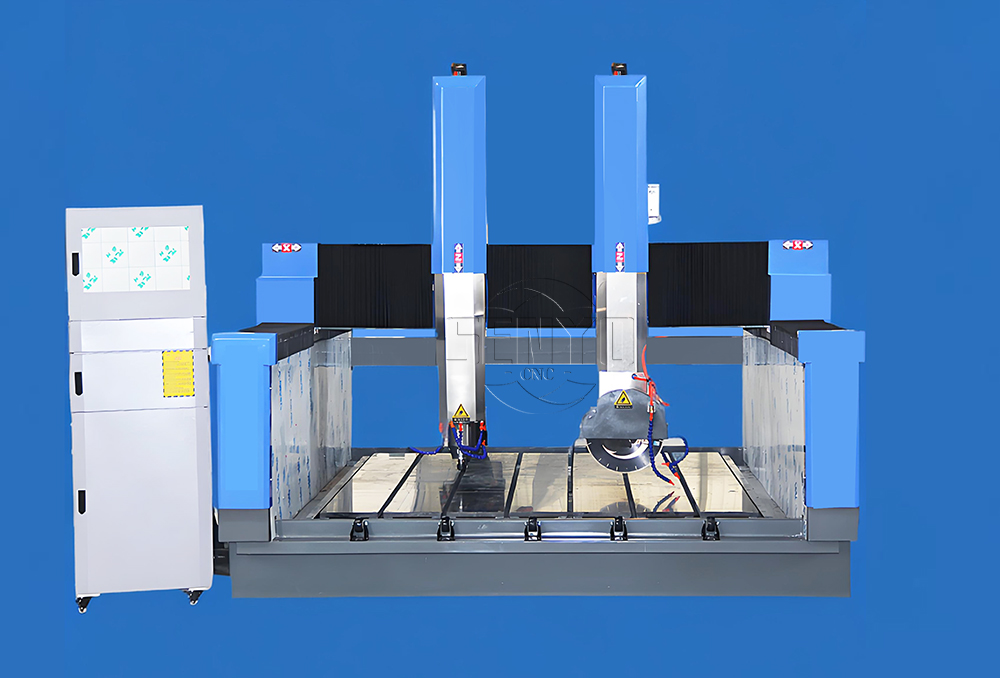

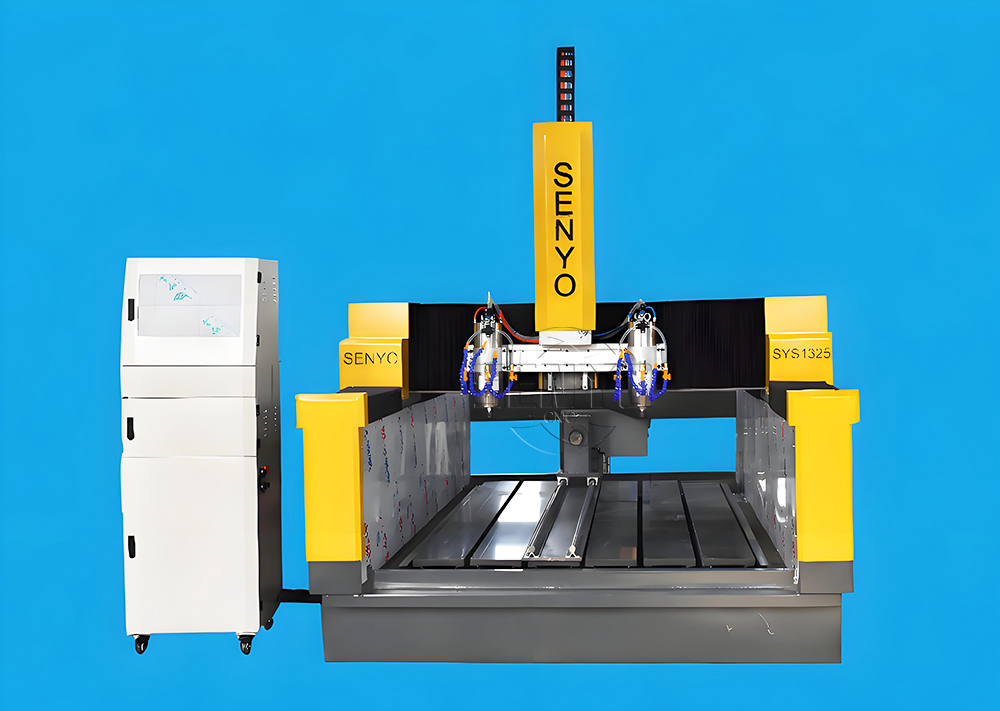

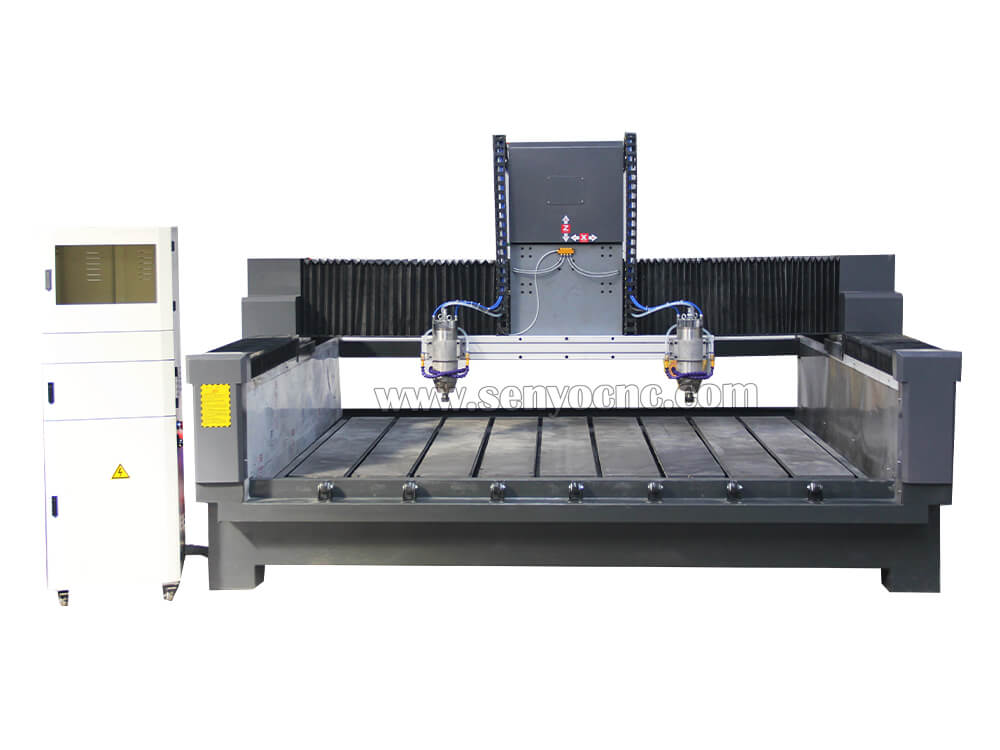

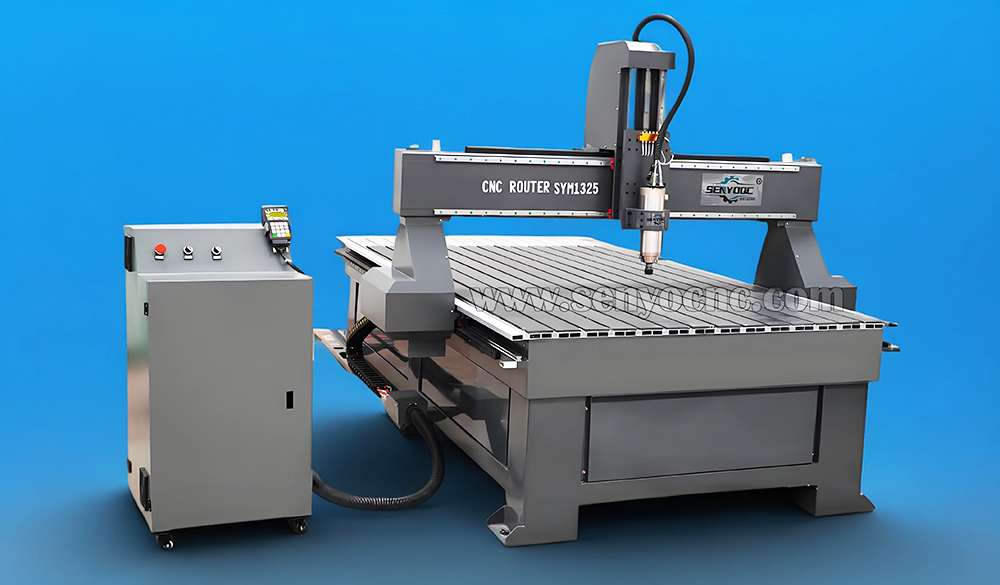

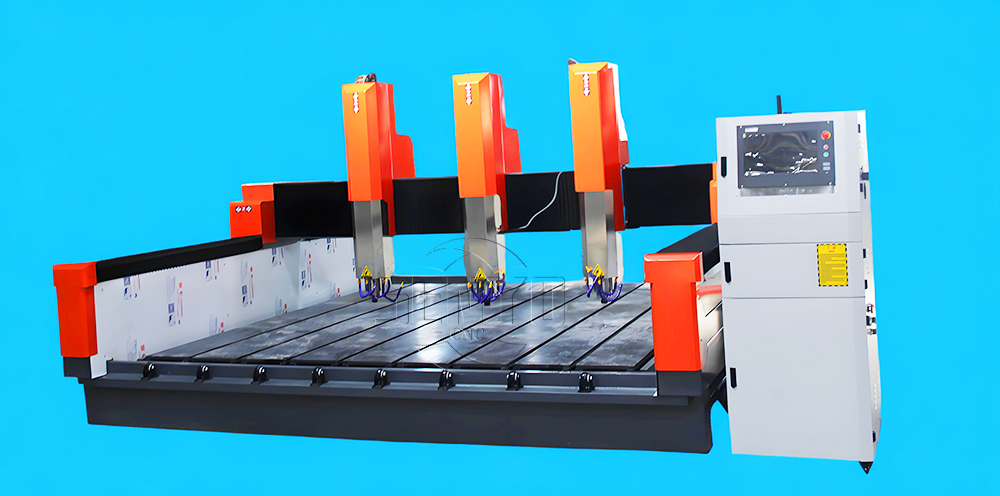

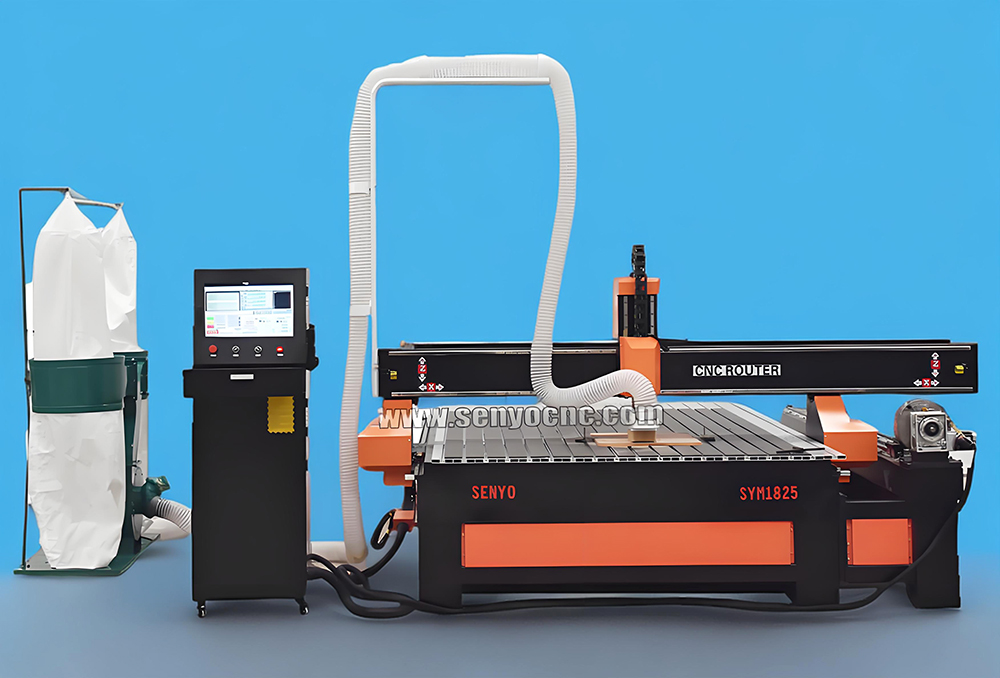

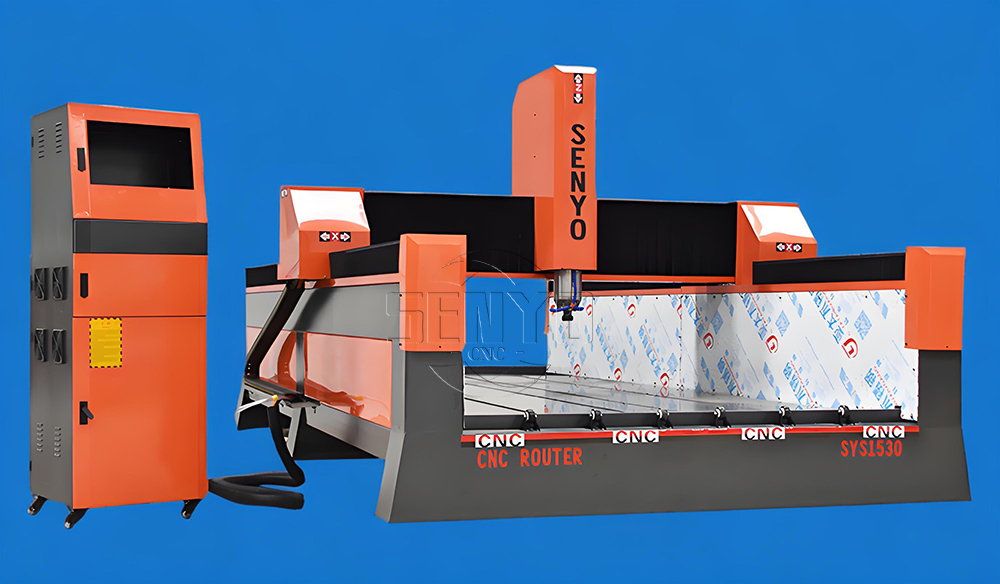

What is an Industrial 5x10 CNC Router for Aluminum Composite Panels?

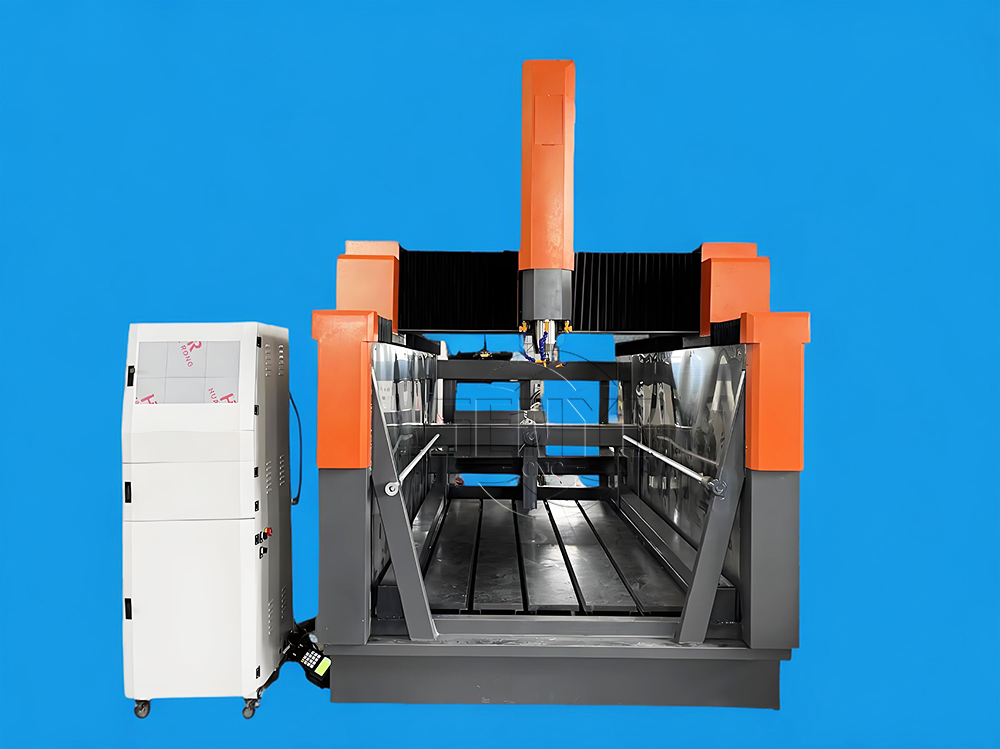

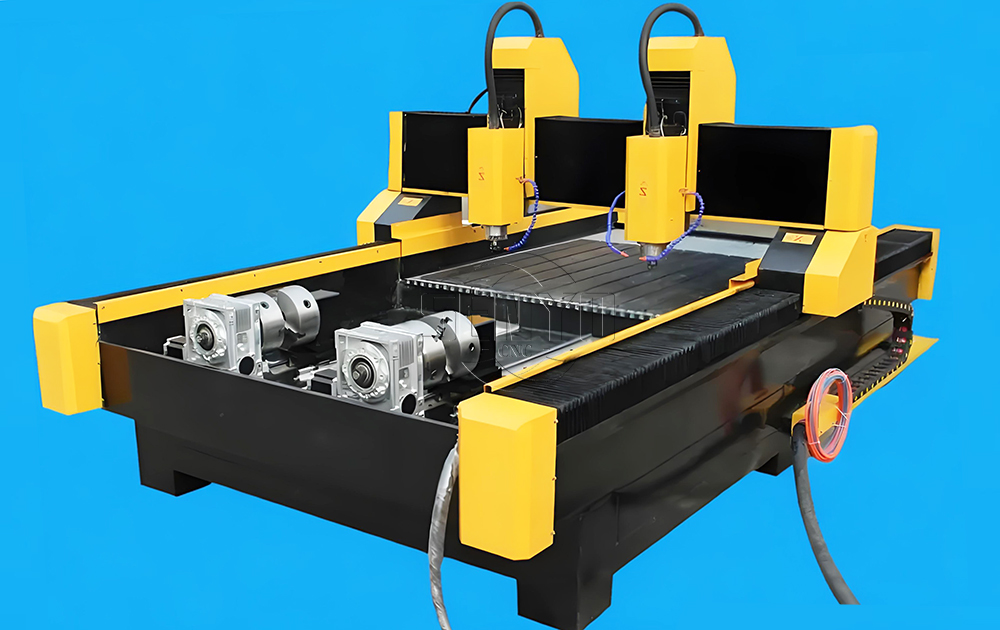

An industrial 5x10 CNC router is a computer-controlled cutting machine that uses precise tool paths to shape, cut, or engrave aluminum composite panels. The working area measures 5 feet by 10 feet, and this is referred to as "5x10." This allows it to process huge ACP sheets in a single run. Its precision-controlled motors and high-speed spindles ensure burr-free edges on even the most delicate designs.

To increase productivity, these routers come with vacuum tables, spindles, and automated tool changers. They employ software to translate design files, like G-code, into machine motions, which makes accurate cuts devoid of human mistakes possible. Various cutting tools that are optimized for aluminum and composite materials are frequently installed on the machines.

This machine is very good at milling, routing, and engraving. Operators can quickly change materials or cut depths with automated control without having to halt production. Dust collection systems and other elements also guarantee a tidy workspace and little downtime.

The 5x10 CNC router is popular among manufacturers, construction companies, and sign-making businesses because it is made to endure the harsh conditions of an industrial setting. It is a vital tool for tasks requiring reliable, high-quality results due to its accuracy, speed, and adaptability.

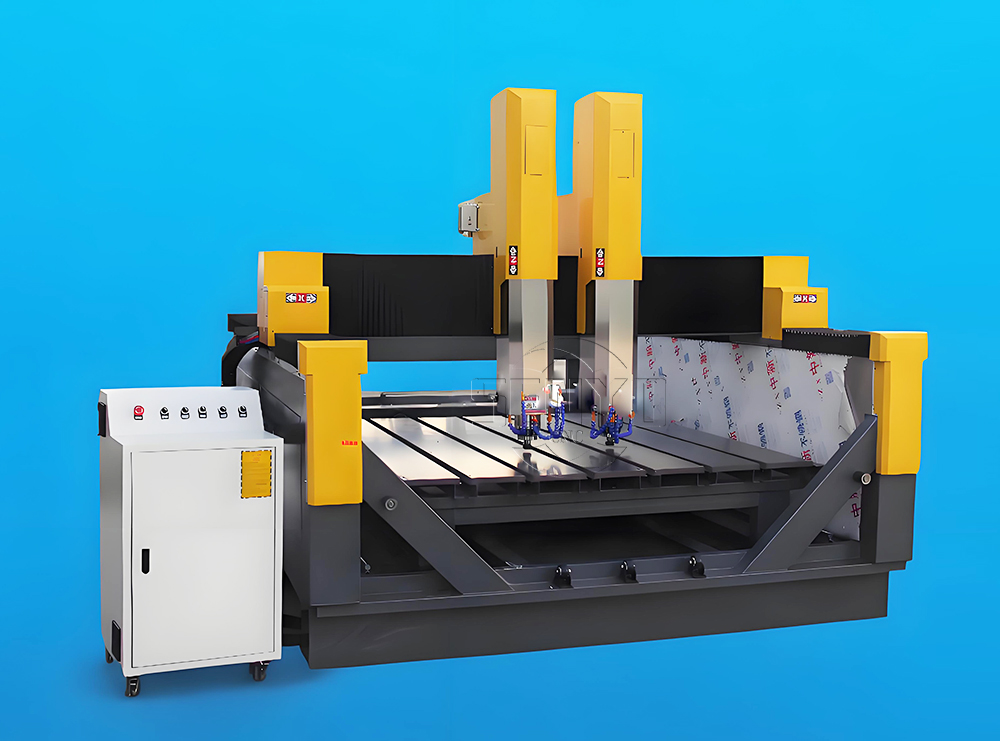

Features of Industrial 5x10 CNC Router for Aluminum

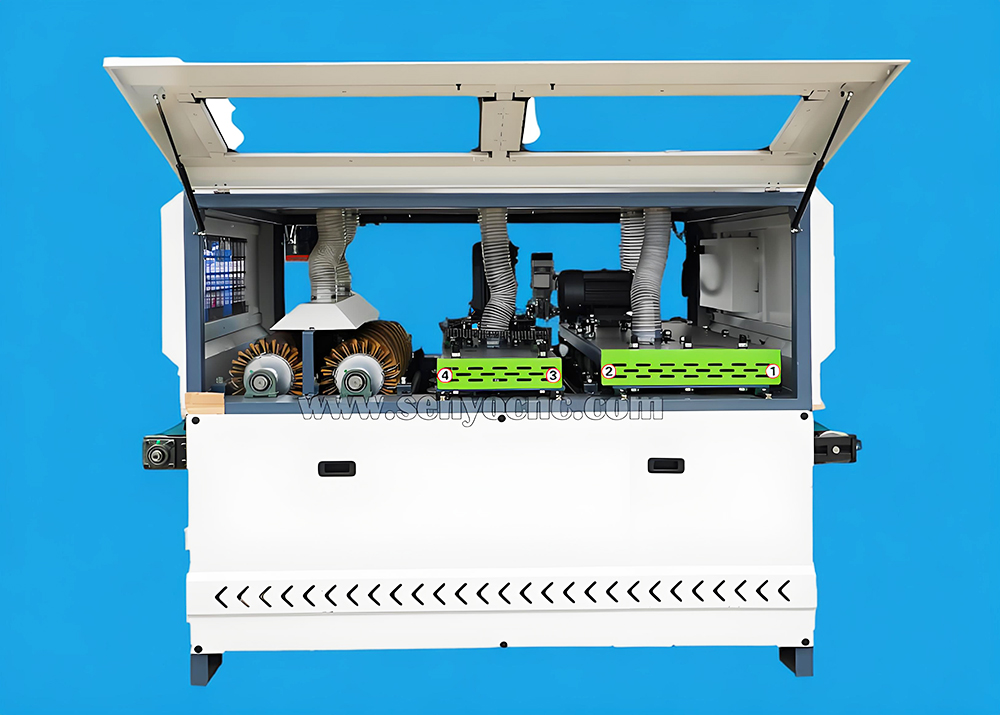

Big size CNC router for aluminum composite panels (ACP) cutting is designed with high strength double driving motors of Y axis, which have a more reasonable design, higher processing speed, easy-operated maintenance, and low fault rate.

High-power air cooling spindle with higher strength and higher efficiency.

Configured with HIWIN linear rail from Taiwan, which is more stable, precise, and lower noise.

Z axis adopts top brand ball screw with industrial level, which can position accurately to make processing effects more perfect.

Helical rack transmission for X, and Y axis.

DSP Control System: USB interface, no need to connect with PC, easy to operate and convenient.

Vacuum table with great absorption strength, and high efficiency for mass production.

Softwares have good compatibility. The CNC router machine for aluminum can be compatible with various CAD/CAM design software such as TYPE3, Artcam, JD, UG, MasterCAM, and PowerMill.

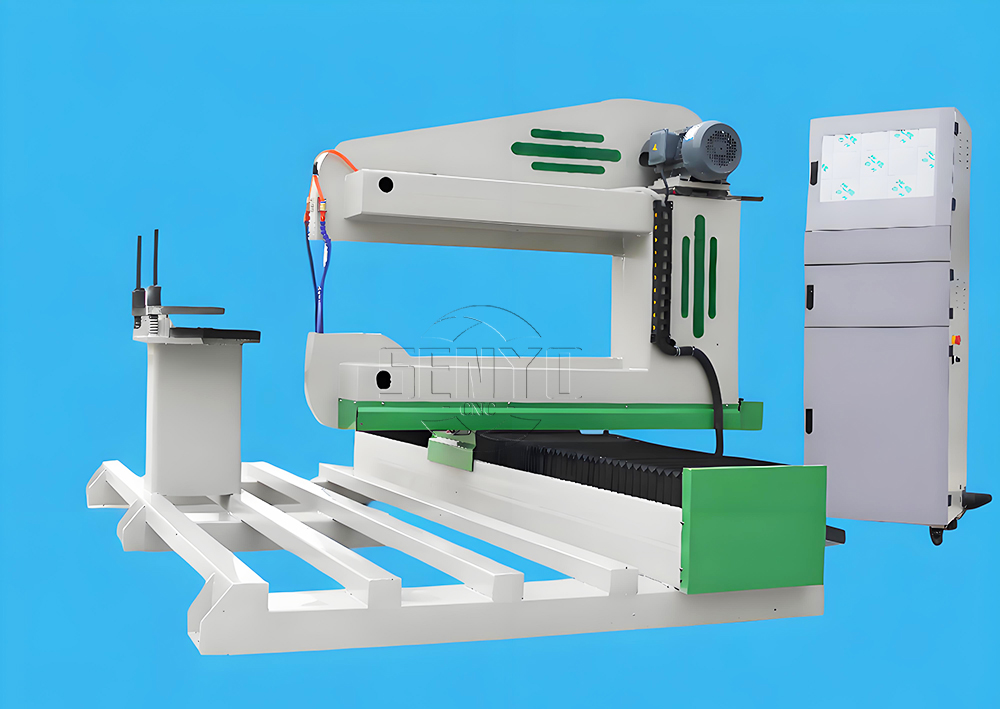

Uploading Roller +Machine with T slot table and Steel water tank

Technical Parameters of Industrial 5x10 CNC Router for Aluminum

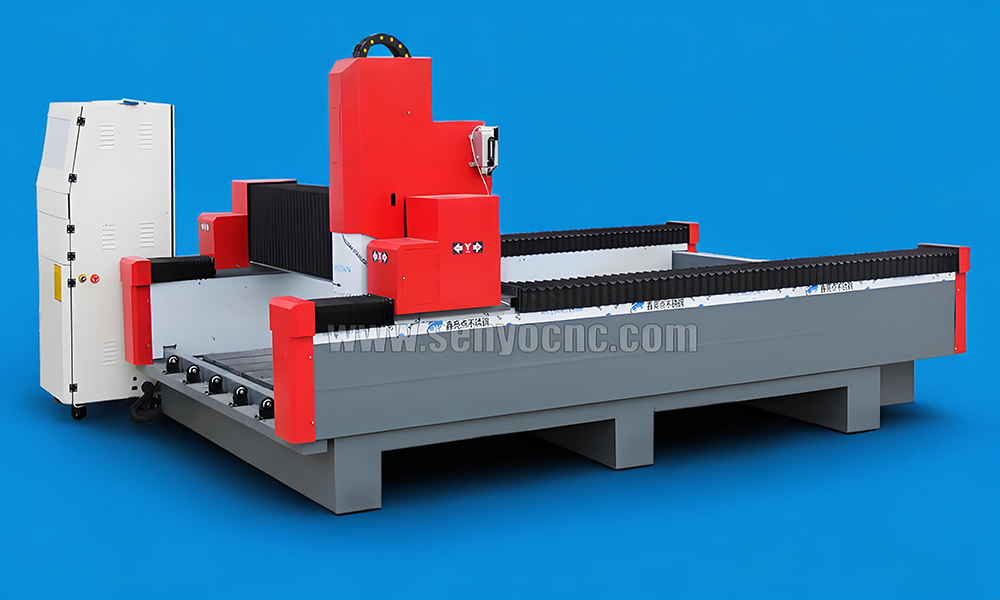

| Model | SYMS1530-A2 With Dust Collect |

| Working Table | T Slot Table With Steel Water Tank |

| Table size | 1500mmx3000mmx200mm |

| Spindle | 5.5KW Air Cooling Spindle (6KW Air Cooling Spindle or HSD Spindle for Option) |

| Max Travelling Speed | 35m/min |

| Max Working Speed | 30m/min |

| Spindle Rotation Speed | 0-24,000rpm |

| Operating system | DSP Control System (NC Studio 53C System for Option) |

| Command | G Code |

| Driver&Motor | Stepper Motor and Leadshine Driver System |

| Transmission | Z axis: Germany Ball Screw X,Y axis: Helical Gear Transmission |

| Guide Rail | Taiwan HIWIN Guide Rail |

| Dust Collecting System | 3KW dust collect(Option) |

| Working Voltage | 220V / 380v, 50hz, 3ph |

| Weight | 1500KG |

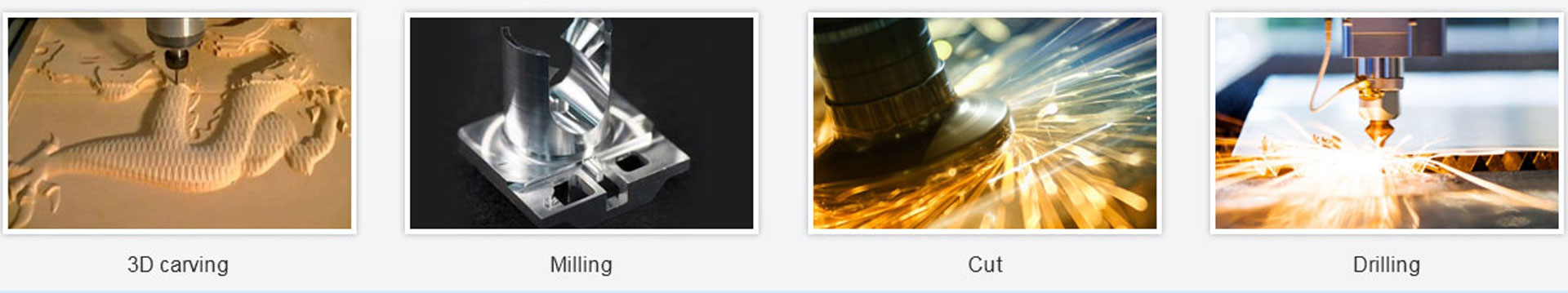

Applications of 5x10 Industrial CNC Router for Aluminum

The 5x10 CNC router is used across a range of industries where aluminum composite panels (ACP) are integral. Here are some of its most common applications.

Architectural cladding and facades

Construction companies use CNC routers to cut aluminum panels for building exteriors and cladding. These panels provide an aesthetic, protective layer to walls, making the structures visually appealing and weather-resistant. The machine can cut intricate shapes or patterns, allowing for custom designs and architectural creativity.

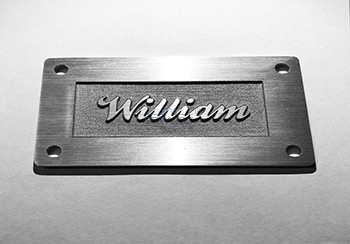

Signage and advertising industry

In the advertising world, ACP is a popular material for outdoor signs, billboards, and display boards. A 5x10 CNC router helps create crisp, precise letters and logos that are durable and resistant to weather conditions. Businesses rely on the router’s ability to handle bulk sign production while maintaining consistent quality.

Interior design and furniture

ACP is also used in interior design projects, such as wall panels, ceilings, and furniture components. With the CNC router, designers can achieve sleek and modern looks with perfectly cut edges. It enables precise routing for custom panel designs used in decorative partitions and cabinetry.

Transport and automotive industry

Lightweight and corrosion-resistant, aluminum composite panels are sometimes used in vehicle interiors and exteriors. The 6x12 CNC router helps manufacturers produce custom vehicle wraps, instrument panels, and interior components with precision and speed.

Mold making and prototyping

CNC routers are also useful in mold-making and rapid prototyping. The machine allows businesses to produce accurate molds or models from ACP sheets, which are commonly used in product development and testing phases.

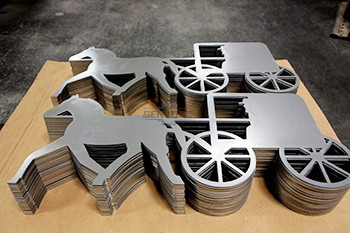

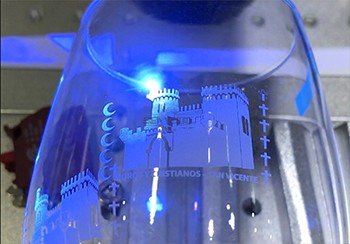

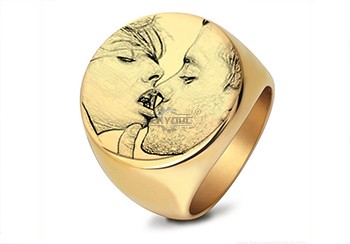

Working Samples Project

Benefits of Using a 5x10 CNC Router for Aluminum Composite Panels

Investing in a 5x10 CNC router offers several key advantages for businesses working with aluminum composite panels.

• High precision and accuracy: CNC routers use advanced software and automated control systems to ensure that every cut is accurate to the design specifications. This precision reduces waste and ensures that even the most complex shapes are cut perfectly, saving time and material costs.

• Large-scale production capability: With a working area of 5 feet by 10 feet, this CNC router can handle large ACP sheets in a single pass. This capability is crucial for businesses that deal with bulk orders or large-format signage, ensuring fast and efficient production without interruptions.

• Time and labor efficiency: The automated nature of the 5x10 CNC router eliminates the need for manual cutting, speeding up the production process. Operators can focus on design and quality control while the machine handles the repetitive tasks, reducing the need for extensive labor.

• Versatility for multiple applications: While primarily designed for ACP processing, the machine can also cut, engrave, and route other materials such as wood, plastic, and acrylic. This versatility makes it an excellent investment for businesses that work with a variety of materials.

• Reduced error and consistency: CNC routers provide consistent results with minimal human error. Once the design is uploaded, the machine performs the task the same way every time, ensuring uniform output across multiple projects.

• Cost savings in the long run: While the initial investment in a 5x10 CNC router may seem high, the long-term savings from reduced labor costs, material waste, and faster production outweigh the upfront costs.

How to Maintain a 5x10 CNC Router for Long-Term Performance

Proper maintenance is the key to keeping your 5x10 CNC router running smoothly for years. A well-maintained machine ensures consistent performance, reduces downtime, and prevents costly repairs. Follow these essential tips to extend the lifespan of your CNC router and keep it operating at its best.

Clean the Machine’s Operating Parts and Surface

Regular cleaning removes dust, debris, and metal particles that can build up over time. A clean workspace ensures smooth movements and prevents components from getting clogged or stuck. Neglecting cleaning can impact accuracy and reduce the machine's efficiency.

Lubricate Rails, Bearings, and Lead Screws

Frequent lubrication minimizes friction between moving parts, preventing wear and tear. Smooth operation ensures the machine runs without jerks or interruptions during work. Use the recommended lubricant to protect components and prolong their lifespan.

Inspect and Calibrate the Spindle

Regular inspection helps you detect unusual noises or signs of overheating early. Calibrating the spindle ensures precise cutting depth and avoids inconsistencies in performance. Neglecting the spindle can lead to imprecise cuts and impact product quality.

Check Wiring and Electrical Components

Tight and secure electrical connections reduce the risk of malfunctions or sudden shutdowns. Loose connections can cause operational errors or damage delicate machine parts. Make it a habit to inspect wiring to avoid unnecessary downtime or repairs.

Update Firmware and Software

Software updates from manufacturers often include performance enhancements and bug fixes. Regular updates ensure smooth and efficient operation without unexpected issues. Outdated software can lead to compatibility issues and affect machine functionality.

Monitor Cooling Systems

Cooling systems are essential when cutting aluminum, which generates heat during processing. Proper cooling prevents overheating that can damage components or reduce precision. Check the cooling system regularly to ensure it is functioning correctly for optimal performance.

Packing & Shipping

1. Outside package: Standard marine export plywood case.

Improved package, much more strong and environmental protection.

For Our Work Steps

1.Before-sale,we will try to know your requirement about our cnc router specification and what kind of work

you will do .then we will offer our best solution for your requirement.

2.During production: we will send photos of machines during making. so you can know more details about

the procession of making your machines.

3.Before shipping,we will take delivery photo and confirm the specification of order to avoid the mistake.

Machine will be adjusted before it is delivered.

4.After shipping: we will sent out the documents for your customs clearance ASAP . and check the

approximate date of arrival.

5.After arrival: we will confirm with you if machine is in good condition.and see if any spare parts missing .

6.About teaching: there are some manual and video about how to use machine , if you have question

about it. we will have professional technicist to help you install and teach how to use through skype ,

calling, video or mail.

Service & Support

1. Our engineers available to service machinery overseas.

2. 2 years guarantee for the whole machine.

3. Technical support by calling, mail, whatsapp and skype. If you have any problems, we will help you to solve it within 12 hours.

4. You will be get free training advice towards our machine in our factory.

5. If you need any component of the machine, we will provide most affordable price for you.

6. Friendly English version manual and operation video CD disk.

• Previous: 4 Axis Bridge Saw Stone Marble Saw Cutter for Processing Bathroom Countertops

• Next: None

Fiber metal Laser Sensor And Its Application

Category: SENYO NEWS 11th Mar, 2021A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

Precision Cutting Stents with Fiber Lasers

A CNC wood router will use 3D machining in relief carving, the effect is more artistic beauty, but also has a strong sense of three-dimensional 3D, realization of this function is to ...

How to Laser Cut Copper and Other Reflective Metals

Laser cutting of mild steel and stainless steel has a long history and has been one of the primary applications for CO2lasers. However CO2lasers have not traditionally offered a good solution for cutting highly reflective materials.Fiber lasers have an emission wavelength of around

Laser Cutting Machine Inspection Process For Manufacture

SENYOCNC Have Strict quality monitoring will be carried out when the parts are in the factory.

How Control Costs Use of UV Printers ?

UV flatbed printers are rapidly being used by more and more manufacturers, thanks to its efficient production efficiency, and the control of production costs also needs to arouse our attention.

Why UV flat printing machine is popular in market ?

For the majority of designers, give full play to the creative ability, the design sample can be arbitrarily modified on the computer, the effect on the computer, is the effect after the finished product, customer satisfaction can be directly produced. UV flat printing pattern fine, rich and clear layers, high artistry, strong three-dimensional sense, many high precision equipment can also print photography and painting style patterns.

How does UV ink jet printer save UV ink?

UV inkjet printer use process is an important consumable UV ink, reasonable use of equipment, can save UV ink , it can be said to be the best choice to directly save the cost. In the process of using some skills you need to be familiar with, the following small make up to share with you:1. Try to us

Waterjet Machine delivery and Shipping

Please tell us your max working size and what materials will cutting , also what max cutting thickeness.If you have Working photo sample please also send us , it will be helpful to choose machine with suitable models .

Waterjet Machine finish manufacture 5axis

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.

Waterjet Machine delivery and Shipping

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation.There are multiple advantages to adding waterjet cutting capabilities to your shop.We are company leading ultrahigh-pressure waterjet system so

How to Create Connected Text – Inkscape for Laser Cutting

Step 1: Create Some TextFirst, we need some text to work with. To create the text, select the Text Tool (keyboard shortcut: T), click somewhere on the canvas, and type your text.You can use the drop-down list on the top left to select your desired font.Step 2: Convert Text to PathNext, we need to tu

Jacob from United States

I am a beginner at CNC, I’ve never used a CNC machine before and with in a day I was carving. An awesome machine for a beginner to learn as hobbyists. I used the manual and the help video. One hour to assemble and test, very friendly and easy to use. It’s a good buy for the money. I would definitely recommend this machine to someone getting into CNCs.

Weinstein from France

I've been using CNC plasma SYP2060-300A and I am very impressed with this unit.

This unit is of higher quality, made in China. Five stars all the way!

12KW Fiber Cutting - 2000X6000mm -- 이병헌 from Korea

Good machine for metal cut ! Thanks Senyo , Its prefect , I like your business patient kind!

I am a furniture manufacturer, and this machine is very good and fast. thanks Senyoqc Team ! from Bangladesh

Metal ArtWork from Denmark

The plasma cutting machine makes my artistic creation more convenient and precise!! Created more artistic ideas and value! Thank you Aillen team!

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen. from

Thanks for 3D CNC Router, so much 3D works, just everyday use machine works.that is what makes the magic happen.

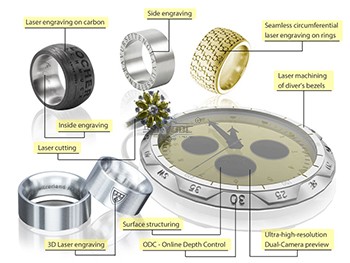

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo from

I'm getting a little bit closer to completing more art deco jewelry use fiber laser marking machine.Thank you Senyo

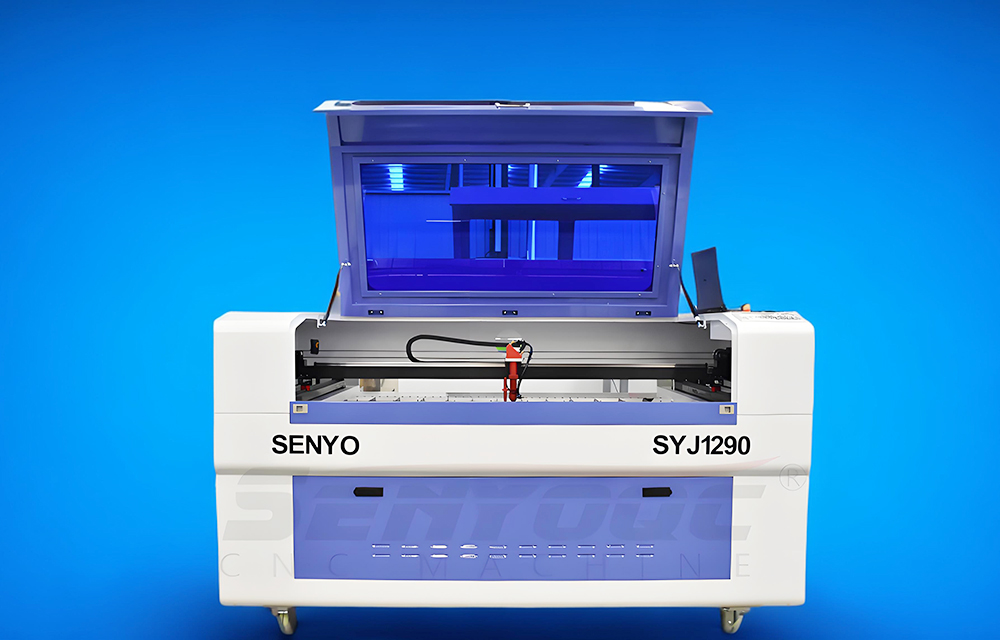

Thank you Senyo for SYJ1290-150W! from

Retired, ex mainframe systems programmer. Now full-time recreational woodworker majoring in puzzles, pens, boxes, Toys and occasional small furniture. Thank you Senyo for SYJ1290-150W!

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing! from Ricky

CNC Router I love woodworking and the Joy in the Journey! It's a Blessing!

CO2 1530H-300W Europe from

CO2 1530H-300W All really well done. these are something ive always wanted to do.

manager@senyocnc.com

manager@senyocnc.com

SENYOCNC

SENYOCNC

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

+86 1525 3141 880

2061579344

2061579344